What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?

- Electronic Potting Material Manufacturer

- November 25, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, automotive electronic encapsulants adhesives, automotive electronic encapsulants adhesives manufacturer, automotive electronic encapsulants adhesives supplier, Automotive potting material manufacturers, Benefits of Potting Electronics, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, circuit board potting compounds, coating for electronic implants, coating heads adhesive application, coating material manufacturer, conformal coating, conformal coating electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, Conformal Coating Material Manufacturer, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coatings market for automotive electronics, Connector Potting Compound, Connector Potting Process, custom automated electronics potting, electronic encapsulants adhesives, electronic encapsulants glue, encapsulants adhesive, UV potting, uv potting compound, uv potting compounded material

What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?

In the automotive industry, electronic components are integral to modern vehicles, powering everything from engine control units (ECUs) and advanced driver-assistance systems (ADAS) to infotainment systems and electric vehicle (EV) battery management. These components operate in harsh environments, exposed to extreme temperatures, vibrations, moisture, and chemicals. Encapsulation adhesives, also known as potting compounds, play a critical role in protecting these sensitive electronics by sealing them against environmental stressors. The title’s specified temperature range of -60°C to 200°C reflects the demanding conditions in automotive applications, such as under-the-hood modules near engines or in cold-weather climates.

Automotive electronics must endure thermal cycling, where temperatures fluctuate rapidly, potentially leading to material degradation, cracking, or failure. Encapsulation adhesives like epoxies, silicones, and polyurethanes provide mechanical support, electrical insulation, and thermal management. However, designing these adhesives involves adhering to specific standards for properties like glass transition temperature (Tg) and tensile modulus to ensure reliability. Additionally, improving thermal aging stability is essential to extend the lifespan of these materials under prolonged heat exposure.

This article delves into the design standards for Tg and tensile modulus in encapsulation adhesives for automotive electronics, drawing from industry practices and standards. It also explores strategies to enhance thermal aging stability, supported by insights from adhesive manufacturers and research. By understanding these aspects, engineers can select and formulate adhesives that meet automotive reliability requirements, such as those outlined in SAE and ISO standards.

Understanding Encapsulation Adhesives in Automotive Contexts

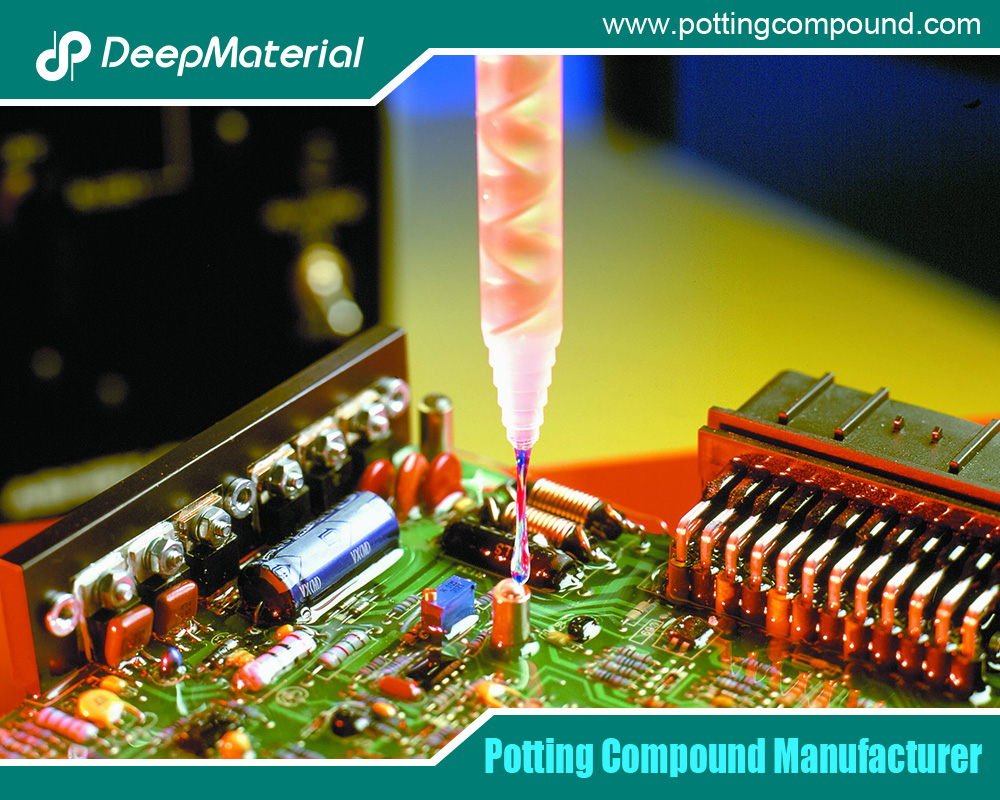

Encapsulation involves filling or coating electronic assemblies with adhesives to create a protective barrier. In automotive electronics, this is crucial for components like sensors, connectors, and power modules that face temperatures from sub-zero winters (-60°C) to high-heat engine compartments (up to 200°C or more). High-temperature-resistant encapsulants, such as those from DELO, are designed for electronic components, achieving high strength at elevated temperatures. Henkel’s potting compounds, including urethanes, offer temperature resistance up to 200°C. EpoxySet products withstand over 250°C with minimal degradation.

Common types include:

- Epoxy Resins: Rigid, with excellent adhesion and chemical resistance, suitable for high-temperature applications up to 260°C.

- Silicone Adhesives: Flexible, with a wide range from -100°C to 200°C, ideal for vibration damping.

- Polyurethanes: Balanced flexibility and toughness, often used for EV batteries.

These materials must comply with automotive standards like AEC-Q100 for reliability testing, which includes thermal shock and aging tests.

Design Standards for Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is a critical property defining the point at which an adhesive transitions from a rigid, glassy state to a more flexible, rubbery state. Below Tg, the material is stiff and brittle; above it, it becomes compliant, which can lead to reduced mechanical strength and potential failure in load-bearing applications. In automotive electronics, where temperatures can reach 200°C, a high Tg is essential to maintain structural integrity during operation.

- Importance of Tg in Automotive Encapsulation

For encapsulation adhesives, Tg directly impacts performance under thermal stress. In high-temperature environments like engine sensors, adhesives with Tg upwards of 250°C are required to prevent softening and ensure electrical insulation. Master Bond highlights adhesives with Tg over 180°C for high-temperature applications, offering optical clarity and physical properties. Standard epoxies have Tg of 40-60°C for Bis-A resins, but Novolac resins can exceed 100°C; silicones typically have lower Tg around -120°C, making them suitable for low-temperature flexibility but requiring careful selection for high-heat stability.

Tg can be optimized by varying polymer composition, such as incorporating fillers or cross-linkers. In EVs, where battery modules generate heat, high-Tg epoxies prevent delamination during thermal cycling.

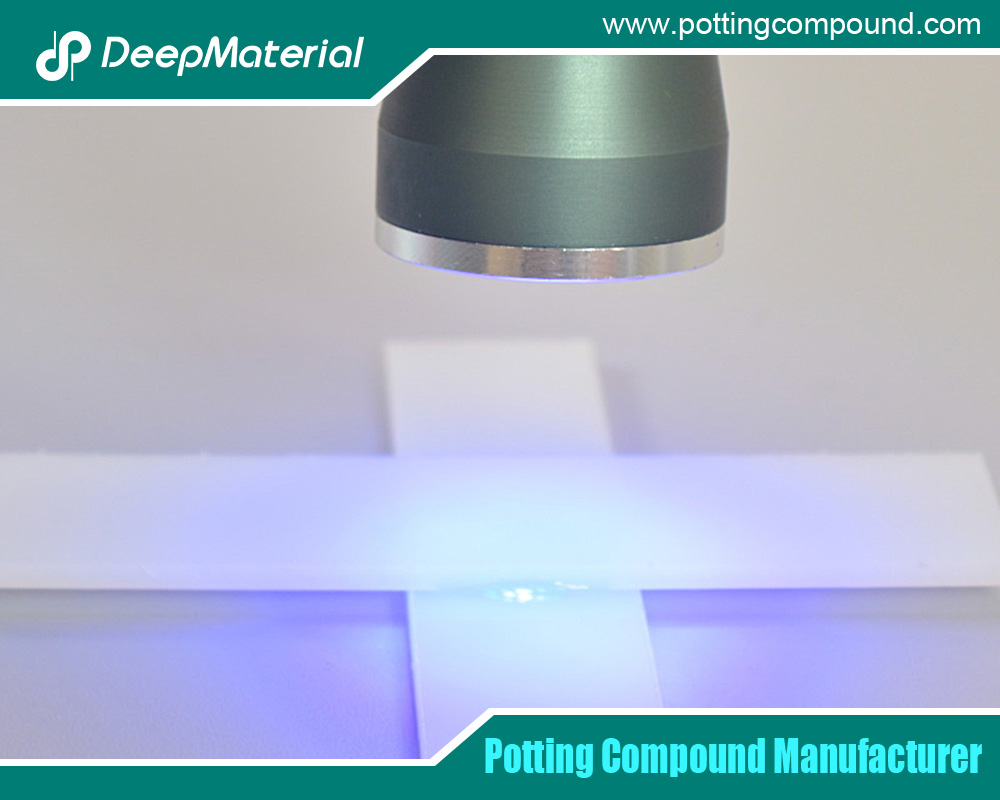

- Measurement and Standards

Tg is measured using Differential Scanning Calorimetry (DSC) per ASTM E1356, which assigns Tg by detecting heat flow changes. Dynamic Mechanical Analysis (DMA) per ISO 6721-7 is also used, providing viscoelastic data. For automotive standards, SAE J774 specifies material properties for encapsulants, emphasizing Tg alignment with operating temperatures. AEC-Q200 requires components to withstand 1000 hours at 150°C, implying adhesives with Tg at least 20-50°C above maximum service temperature to avoid rubbery transition.

Design guidelines recommend Tg > 150°C for under-hood applications to ensure the adhesive remains glassy up to 200°C. For example, INCURE’s high-Tg epoxies are tailored for automotive use, with Tg exceeding 150°C. In practice, a safety margin of 20-30°C above the maximum temperature is standard to account for thermal gradients.

- Challenges and Considerations

Low Tg can lead to creep or loss of adhesion under heat, while excessively high Tg may cause brittleness at low temperatures (-60°C). Balancing Tg with other properties is key; for instance, hybrid epoxies combine high Tg with flexibility.

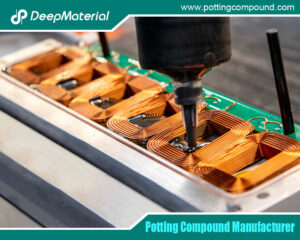

Design Standards for Tensile Modulus

Tensile modulus, or Young’s modulus, measures an adhesive’s stiffness under tensile stress, indicating resistance to deformation. In encapsulation, it ensures the material can withstand mechanical loads from vibrations and thermal expansion without cracking or delaminating.

- Role in Automotive Electronics

Automotive encapsulants need high tensile modulus for structural integrity in high-vibration environments like vehicle chassis. For example, adhesives with 4-7 GPa modulus are used in brake linings and electrical components. Master Bond’s systems feature high tensile modulus and compressive strength for potting. In electronics, modulus affects stress distribution; too high can transfer vibrations to components, while too low may not provide adequate protection.

For liquid crystal polymers (LCP) in automotive, tensile modulus can reach 1.20×10^6 psi (8.4×10^3 MPa), influencing encapsulant choice. CAPLINQ’s non-conductive adhesives show modulus from 175 N/mm² to 22,000 N/mm².

- Standards and Testing

SAE standards for automotive adhesives, like SAE AMS-A-25463, address modulus for encapsulants, suggesting elastomeric materials with modulus <172 MPa for flexibility. However, for rigid epoxies, higher values (1-10 GPa) are common. IPC-HDBK-850 provides guidelines for encapsulation design, including modulus selection based on application. Testing follows ASTM D638 for tensile properties.

In automotive, modulus should be 1-5 GPa for epoxies to balance stiffness and damping, ensuring compatibility with substrate CTE (coefficient of thermal expansion) to minimize stress at -60°C to 200°C. For EV batteries, ITW’s Insulcast products emphasize modulus for heat sink bonding.

- Balancing Modulus with Temperature

At low temperatures, high modulus prevents brittleness; at high, it maintains shape. Standards like ISO 527 require modulus testing across temperatures.

Improving Thermal Aging Stability

Thermal aging stability refers to an adhesive’s ability to resist degradation over time at elevated temperatures, preventing yellowing, cracking, or loss of properties. In automotive electronics, where components may operate for 15+ years, enhancing stability is vital.

- Factors Affecting Thermal Aging

Aging involves oxidation, chain scission, or cross-linking, accelerated by heat. Studies on epoxy adhesives use thermogravimetric analysis (TGA) for weight loss and adhesion degradation, enabling lifetime predictions. Silicones offer inherent stability up to 200°C.

- Strategies for Improvement

- Additive Incorporation: Omnistab additives enhance silicone thermal stability by scavenging free radicals. Panacol’s MLA adhesives resist yellowing during aging.

- Formulation Optimization: High-thermal-conductivity organosilicon potting adhesives use fillers like alumina to dissipate heat, reducing aging. Epoxies with aromatic structures improve stability.

- Material Selection: Silicones for flexibility and stability; epoxies for strength, with high-Tg variants. High-temperature aging “hardens” adhesives, improving robustness.

- Design Adjustments: Smaller joint sizes reduce strain. TA Instruments’ tools like DSC and TGA optimize TIMs.

- Testing Protocols: Accelerate aging per AEC-Q101, simulating 1000 hours at 175°C.

These methods ensure adhesives maintain performance over the vehicle’s lifecycle.

Case Studies and Best Practices

In EVs, polyurethane encapsulants protect batteries from thermal runaway. DELO’s defined encapsulation protects sensors. Best practices include surface preparation, vacuum potting, and CTE matching.

Conclusion

Encapsulation adhesives for automotive electronics must navigate extreme temperatures, with Tg standards favoring values >150°C and tensile modulus 1-5 GPa for balance. Improving thermal aging via additives and formulations ensures longevity. As electrification advances, ongoing innovations will refine these materials, enhancing vehicle reliability.

For more about what are the design standards for the glass transition temperature (Tg) and tensile modulus of automotive electronic encapsulants adhesives, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Conformal Coating vs. Potting: What’s the Difference for Your PCB?

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

Tags

Related Posts

Common Mistakes to Avoid When Applying Conformal Coating

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB