Potting Compound for RF Devices

In electronics, Radio Frequency (RF) devices play a pivotal role in enabling wireless communication across various sectors. RF components are omnipresent, transmitting and receiving data seamlessly from smartphones to IoT devices. However, ensuring the reliability and performance of these devices amidst challenging environmental conditions is a constant endeavor for engineers and manufacturers. One key solution that has gained prominence in recent years is the utilization of potting compounds for RF devices. In this article, we delve into the significance of potting compounds and how they enhance the functionality and longevity of RF devices.

Understanding RF Devices:

RF devices encompass a wide array of components, such as amplifiers, filters, oscillators, and antennas. These devices operate within the radio frequency spectrum, typically ranging from 3 kHz to 300 GHz. Due to their susceptibility to interference and environmental factors, ensuring the integrity of RF devices is paramount for optimal performance.

Challenges Faced by RF Devices:

RF devices encounter numerous challenges that can compromise their functionality and longevity. Factors such as moisture ingress, thermal stress, vibration, and mechanical shock pose significant threats to the reliability of these components. Exposure to harsh chemicals or extreme temperatures can also exacerbate degradation, leading to performance issues and, ultimately, device failure.

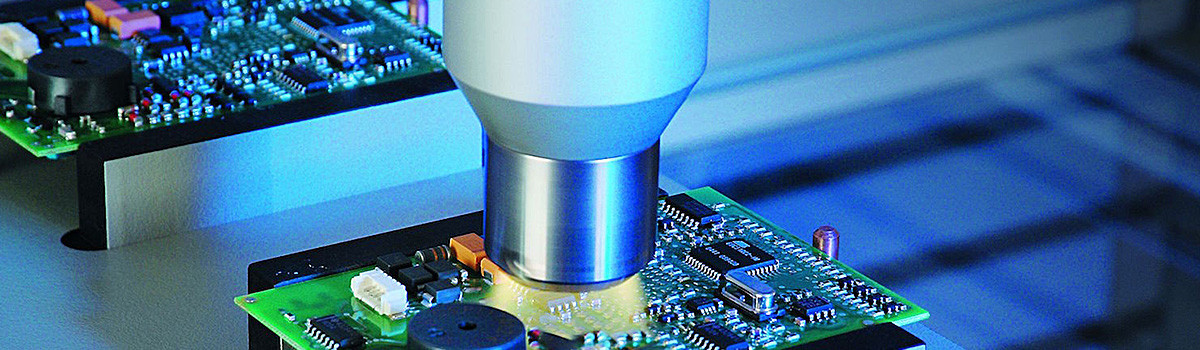

The Role of Potting Compounds:

Potting compounds serve as a protective barrier for RF devices, encapsulating sensitive components and shielding them from external influences. Composed of various materials such as epoxies, silicones, and polyurethanes, potting compounds offer a myriad of benefits, including:

1. Environmental Protection:

Potting compounds create an airtight seal around RF devices, preventing moisture ingress and safeguarding against corrosion. This is particularly crucial for outdoor applications or devices deployed in harsh industrial environments where exposure to moisture and contaminants is inevitable.

2. Thermal Management:

RF devices are susceptible to overheating, which can degrade performance and reliability. Potting compounds with excellent thermal conductivity help dissipate heat efficiently, ensuring optimal operating temperatures and mitigating the risk of thermal-induced failures.

3. Mechanical Stability:

Vibration and mechanical shock can compromise the structural integrity of RF devices, leading to component misalignment or solder joint fractures. Potting compounds act as shock absorbers, providing mechanical support and enhancing the device’s overall durability.

4. Electrical Insulation:

Potting compounds offer electrical insulation, preventing short circuits and signal interference. This is crucial for maintaining signal integrity and ensuring the proper functioning of RF circuits, especially in high-frequency applications where even minor disruptions can have significant ramifications.

5. Chemical Resistance:

Specific environments may expose RF devices to corrosive chemicals or solvents, which can degrade materials and compromise performance. Potting compounds with robust chemical resistance properties provide an additional layer of protection, extending the device’s lifespan in chemically aggressive environments.

Conclusion:

In conclusion, potting compounds are pivotal in enhancing RF devices’ reliability, performance, and longevity. Potting compounds address the myriad challenges RF components face by providing environmental protection, thermal management, mechanical stability, electrical insulation, and chemical resistance. As the demand for robust and reliable wireless communication continues to escalate, integrating high-quality potting compounds remains indispensable for ensuring the seamless operation of RF devices across various applications.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

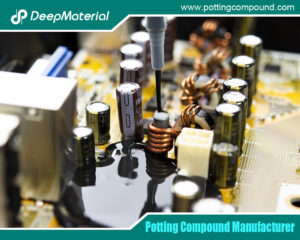

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

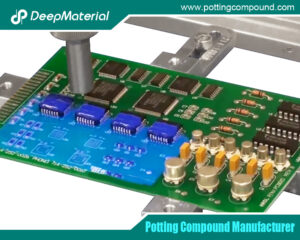

Potting Compound for PCB

Potting Compound for PCB A potting compound is a liquid or semi-liquid material that is poured or injected over a PCB or electronic assembly, then

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds Electronic potting compounds play a vital role in the electronics industry. They can

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices In modern industrial manufacturing, encapsulating materials are widely used in numerous

A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies In the field of electronic manufacturing, the encapsulation process of printed

Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation During the operation of electronic devices, the PCB (Printed Circuit

A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs In modern electronic devices, the printed circuit board (PCB) plays a central