Optically Clear Potting Compound

Optically apparent potting compounds are crucial in various industries, offering transparency and protection for sensitive electronic components. These compounds are designed to provide excellent optical clarity while delivering robust protection against environmental factors such as moisture, chemicals, and physical impact. In this category, we explore optically clear potting compounds’ features, applications, and benefits through a series of questions.

Table of Contents

ToggleWhat is an optically clear potting compound?

An optically clear potting compound is a specialized material encapsulating electronic components while maintaining exceptional optical clarity. Unlike traditional potting compounds, which may be opaque or translucent, optically apparent potting compounds are formulated to provide a transparent, glass-like appearance, allowing for high light transmission and minimal distortion of visual elements such as indicators, displays, or LEDs.

The key characteristics of an optically clear potting compound include:

High Transparency: Optically apparent potting compounds offer excellent light transmission properties, allowing for the passage of light with minimal absorption or scattering. This ensures that visual elements within the encapsulated device remain visible and legible without distortion or color shift.

Low Haze: Optically apparent potting compounds exhibit low haze, meaning they have minimal cloudiness or opaqueness when cured. This results in a clear, sharp appearance that enhances the aesthetic appeal of the encapsulated device and maintains the integrity of optical displays or indicators.

UV Stability: UV stability is crucial for optically clear potting compounds, especially in outdoor or high-UV environments. These compounds are formulated to resist yellowing, discoloration, or degradation when exposed to UV radiation over time, ensuring long-term optical clarity and durability.

Chemical Resistance: Optically clear potting compounds often possess excellent chemical resistance, protecting encapsulated components from exposure to solvents, fuels, oils, and other harsh chemicals. This prevents chemical damage, discoloration, or deterioration of the material, maintaining its optical properties and performance.

Thermal Stability: Optically clear potting compounds may also offer high thermal stability, allowing them to withstand temperature extremes without significant changes in optical clarity or physical properties. This ensures reliable performance and protection for encapsulated components in diverse operating environments.

Optically apparent potting compounds find applications in various industries, including electronics, automotive, lighting, and displays, where optical clarity is critical for functionality, aesthetics, and user experience. Their ability to provide transparent encapsulation while offering robust protection makes them indispensable for applications requiring visual appeal and reliable performance.

How does an optically clear potting compound differ from traditional potting compounds?

Optically apparent potting compounds differ from traditional potting compounds primarily in their optical properties and intended applications. Here are the key differences between the two:

Optical Clarity: The most significant difference between optically clear and traditional potting compounds is their optical clarity. Optically apparent compounds are formulated to provide exceptional transparency, allowing for high light transmission and minimal distortion of visual elements such as indicators, displays, or LEDs. In contrast, traditional potting compounds may be opaque, translucent, or cloudy, obscuring visual elements and compromising aesthetics.

Low Haze: Optically clear potting compounds typically exhibit low haze, meaning they have minimal cloudiness or opaqueness when cured. This results in a clear, sharp appearance that enhances the aesthetic appeal of encapsulated devices and maintains the integrity of optical displays or indicators. Traditional potting compounds may have higher haze levels, which can diminish visibility and affect the readability of visual elements.

UV Stability: Optically apparent potting compounds are formulated to resist yellowing, discoloration, or degradation when exposed to UV radiation over time. This UV stability is essential for outdoor or high-UV applications where prolonged exposure to sunlight may occur. In contrast, traditional potting compounds may not offer the same level of UV resistance, leading to yellowing or degradation of the material over time.

Are optically clear potting compounds UV stable?

Optically apparent potting compounds, commonly used for encapsulating electronic components or optical devices, are designed to provide excellent transparency while protecting against environmental factors such as moisture, dust, and mechanical stress. However, their UV stability can vary depending on the formulation and intended application.

UV stability refers to a material’s ability to withstand exposure to ultraviolet (UV) radiation from sunlight or artificial sources without undergoing significant degradation. UV radiation can cause yellowing, embrittlement, or loss of transparency in certain materials over time.

Many optically clear potting compounds are formulated with additives such as UV stabilizers to enhance their resistance to UV radiation. These stabilizers absorb or block UV light, thereby reducing its harmful effects on the material. However, the effectiveness of UV stabilizers can diminish over time due to prolonged exposure or environmental conditions.

The UV stability of optically clear potting compounds is influenced by various factors, including the type and concentration of UV stabilizers, the chemical composition of the resin matrix, and the thickness of the cured material. Compounds with higher levels of UV stabilizers and more robust resin systems exhibit better UV resistance.

It’s important to note that while many optically clear potting compounds offer good UV stability, they may not be entirely immune to UV-induced degradation. Extended exposure to intense UV radiation, particularly in outdoor applications, can still lead to gradual changes in appearance or properties over time.

To ensure adequate UV protection, manufacturers may recommend additional measures such as incorporating UV-blocking coatings or enclosures, limiting exposure to direct sunlight, or selecting compounds formulated explicitly for outdoor use. Additionally, periodic inspection and maintenance can help detect any signs of UV-related deterioration and prevent potential issues.

While optically clear potting compounds can be formulated to offer UV stability, their resistance to UV radiation may vary depending on the formulation and environmental conditions. Proper selection and application and proactive maintenance are essential for maximizing the longevity and performance of optically clear potted components in UV-exposed environments.

Can optically clear potting compounds to withstand extreme temperatures?

Optically apparent potting compounds are specialized materials encapsulating electronic components while maintaining optical transparency. These compounds are engineered to protect factors such as moisture, chemicals, and physical impact, allowing lightness through with minimal distortion. However, their ability to withstand extreme temperatures depends on their specific formulation and intended application.

Optically apparent potting compounds can withstand a wide range of temperatures, including high and low extremes. Manufacturers often formulate these compounds using epoxy resins, silicones, or polyurethanes, which offer different temperature resistance properties.

For applications requiring resistance to high temperatures, manufacturers may incorporate heat-resistant additives or use thermally stable resin systems. These compounds can typically withstand temperatures ranging from -40°C to over 150°C, making them suitable for use in environments where heat generation or exposure to elevated temperatures is a concern.

However, extreme temperatures beyond this range may pose challenges. For example, prolonged exposure to temperatures above the upper limit of a compound’s temperature range can cause degradation, leading to loss of optical clarity, changes in mechanical properties, or even failure of the encapsulated components. Similarly, exposure to extremely low temperatures can affect the flexibility and durability of the potting material, compromising its effectiveness as a protective barrier.

To enhance temperature resistance, manufacturers may employ strategies such as optimizing the curing process, selecting additives with superior thermal stability, or customizing formulations based on specific application requirements. Additionally, proper encapsulation techniques, such as ensuring thorough coverage and minimizing air voids, can help improve optically apparent potting compounds’ overall performance in extreme temperatures.

While optically clear potting compounds can offer excellent optical transparency and protection for electronic components, their ability to withstand extreme temperatures depends on the formulation, curing process, and application environment. By selecting the appropriate materials and techniques, engineers can ensure that these compounds meet the desired temperature resistance requirements for various applications.

How do these compounds protect against moisture ingress?

Various compounds protect against moisture ingress through their unique properties and mechanisms of action. These compounds are crucial in diverse industries ranging from construction to electronics, where exposure to moisture can lead to degradation, corrosion, or malfunction. Here are some common compounds and how they provide protection:

- Silicone Sealants: Silicone sealants are widely used for their excellent water resistance properties. They form durable, flexible seals that prevent moisture ingress into joints, gaps, or seams in buildings, automobiles, and electronic devices. Silicone’s inherent hydrophobic nature repels water, effectively sealing out moisture and preventing damage.

- Epoxy Resins: Epoxy resins are popular in coatings and adhesives due to their high chemical and moisture resistance. When cured, epoxy forms a rigid, impermeable barrier that shields surfaces from moisture ingress. This protective barrier prevents corrosion, delamination, and other forms of metal, concrete, and wood degradation.

- Polyurethane Coatings: Polyurethane coatings provide robust protection against moisture intrusion in various applications, including flooring, marine structures, and automotive coatings. These coatings create a seamless, waterproof barrier that resists moisture penetration while offering excellent durability and flexibility.

- Desiccants: Desiccants such as silica gel or molecular sieves actively absorb moisture from the surrounding environment, effectively reducing humidity levels and preventing moisture-related damage. These compounds are commonly used in packaging materials, electronic devices, and pharmaceutical products to maintain dry conditions during storage and transportation.

- Corrosion Inhibitors: Corrosion inhibitors are additives incorporated into coatings, lubricants, and metal treatments to protect against moisture-induced corrosion. These inhibitors form a protective film on metal surfaces, which acts as a barrier against moisture and corrosive agents, thus extending the lifespan of metal components and structures.

- Waterproof Membranes: Waterproof membranes, typically made from materials like bitumen, PVC, or EPDM rubber, are used in construction for roofing, foundation waterproofing, and underground structures. These membranes provide a continuous, impenetrable barrier that prevents water ingress into buildings, ensuring structural integrity and longevity.

These compounds offer protection against moisture ingress through various mechanisms, such as forming barriers, absorbing moisture, or inhibiting corrosion. By effectively sealing out moisture, they help preserve the integrity and performance of materials and structures in various applications.

Are optically clear potting compounds resistant to chemicals?

Optically apparent potting compounds, often used in electronic and optical applications, offer transparency while protecting sensitive components. Their resistance to chemicals varies depending on the specific formulation and intended application. While many optically clear potting compounds are designed to resist certain chemicals, complete resistance to all chemicals may not be achievable due to the diverse nature of chemical substances.

The chemical resistance of optically clear potting compounds primarily depends on the type of resin used in their formulation. Epoxy resins, for instance, are commonly employed in these compounds due to their optical clarity and mechanical properties. Epoxy-based potting compounds resist various chemicals, including solvents, oils, and acids. However, they may degrade in the presence of strong acids or bases.

Silicone-based optically clear potting compounds are also popular choices, especially in applications where flexibility and thermal stability are crucial. Silicones typically offer excellent resistance to moisture, UV radiation, and many chemicals, making them suitable for outdoor and harsh environments. They are often preferred for applications where exposure to chemicals like acids, alkalis, and solvents is anticipated.

In addition to the base resin, additives, and fillers can influence the chemical resistance of potting compounds. Reinforcing agents such as silica or glass microspheres can enhance chemical resistance by providing a barrier against chemical ingress. However, certain additives might reduce resistance to specific chemicals or introduce new vulnerabilities.

Optically apparent potting compounds may still experience degradation despite their chemical resistance when exposed to aggressive chemicals or extreme conditions. Compatibility testing should be conducted to determine the suitability of a specific potting compound for a given application. Manufacturers often provide data sheets detailing chemical resistance properties to aid in material selection.

While optically clear potting compounds can resist various chemicals, their effectiveness depends on factors such as resin type, additives, and application conditions. Careful consideration of these factors is essential to ensure optimal performance and longevity in diverse operating environments.

What are the typical curing mechanisms for these compounds?

Curing mechanisms vary depending on the compound being cured, but some standard methods include thermal, UV, and chemical curing.

- Thermal Curing: This is one of the most traditional methods and involves the application of heat to initiate the curing reaction. Typically, a catalyst or initiator is added to the compound, which reacts with the polymer chains when heated, causing them to crosslink and form a solid network. The heat accelerates the reaction kinetics, and as the temperature increases, so does the curing rate. Examples of materials cured thermally include epoxies, polyurethanes, and silicones.

- UV Curing: UV curing relies on ultraviolet (UV) light to initiate the process. Photoinitiators are added to the compound, which absorbs UV radiation and generates reactive species such as free radicals or cations. These reactive species then initiate polymerization of the monomers or oligomers present in the material, leading to crosslinking and curing. UV curing is often preferred for its rapid curing times, energy efficiency, and the ability to cure specific areas selectively. It is commonly used in adhesives, coatings, and dental materials.

- Chemical Curing: Chemical curing involves using chemical reactions to initiate curing without heat or light. It can include reactions such as oxidation, addition reactions, or condensation reactions. For example, in the case of moisture-curing adhesives or sealants, curing occurs through the reaction of functional groups with moisture present in the environment, forming cross links and curing the material. Chemical curing is often used when heat or light is not feasible or practical.

These curing mechanisms are crucial in transforming liquid or semi-solid compounds into solid materials with the desired strength, flexibility, and durability. The choice of curing method depends on factors such as the specific application, desired curing speed, environmental considerations, and the properties required in the final cured material.

Can optically clear potting compounds be customized for specific applications?

Yes, optically clear potting compounds can be customized for specific applications, offering a range of properties tailored to meet particular requirements. These compounds, often made of epoxy or silicone materials, encapsulate electronic components, sensors, LEDs, and other devices where optical clarity is crucial for performance or aesthetics.

Customization of these compounds involves several key aspects:

- Optical Properties: Optically clear potting compounds can be formulated to have specific optical properties such as refractive index, transmission spectrum, and light diffusion characteristics. These properties are crucial for optimal performance in applications like optical sensors or LED lighting, where clarity and light transmission efficiency are critical.

- Mechanical Properties: The mechanical properties of potting compounds, such as flexibility, hardness, and impact resistance, can be adjusted based on the application’s requirements. For example, UV resistance and weatherability may be essential factors to consider in outdoor applications.

- Chemical Resistance: Custom formulations can be developed to resist specific chemicals or environmental conditions, ensuring the longevity and reliability of the encapsulated components in harsh operating environments.

- Thermal Conductivity and Stability: Optically clear potting compounds can be engineered to have tailored thermal conductivity properties, allowing for efficient heat dissipation from enclosed components. Additionally, thermal stability at elevated temperatures is essential for applications subjected to heat cycling or high operating temperatures.

- Curing Process: The curing process of potting compounds can be adjusted to accommodate different production requirements, such as room temperature, heat curing, or UV curing. This flexibility enables manufacturers to optimize production efficiency and compatibility with specific assembly processes.

- Adhesion Properties: Customized adhesion properties can be incorporated into the formulation to ensure strong bonding to various substrates, including metals, plastics, and ceramics, enhancing the durability and reliability of the encapsulated devices.

Optically clear potting compounds offer a versatile solution for a wide range of applications requiring optical clarity and protection of sensitive components. By customizing optical, mechanical, chemical, thermal, curing, and adhesion properties, these compounds can be precisely tailored to meet the specific performance and environmental requirements of diverse applications, ultimately enhancing product performance and reliability.

What are the typical applications of optically clear potting compounds?

Optically apparent potting compounds find widespread applications across various industries due to their unique properties. Here are some typical applications:

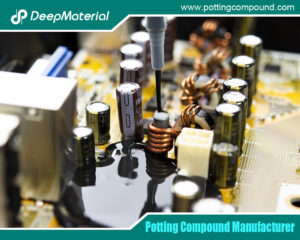

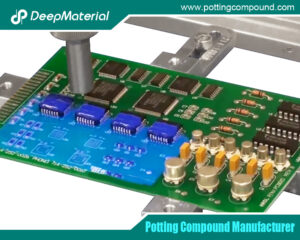

- Electronics Encapsulation: Optically apparent potting compounds are extensively used for encapsulating electronic components like LEDs, sensors, and displays. The transparency of these compounds allows for efficient transmission of light, making them ideal for applications where visibility of the components is necessary, such as in automotive displays, consumer electronics, and LED lighting systems.

- Solar Panel Encapsulation: Optically apparent potting compounds encapsulate photovoltaic cells in solar panel manufacturing. These compounds protect against environmental factors such as moisture, dust, and mechanical stress while allowing maximum light transmission to enhance the efficiency of solar panels.

- Medical Devices: Optically apparent potting compounds are employed in medical device manufacturing to encapsulate sensitive electronic components in imaging equipment, diagnostic devices, and wearable health monitors. The biocompatibility and transparency of these compounds are crucial for ensuring safe and accurate operation of medical devices.

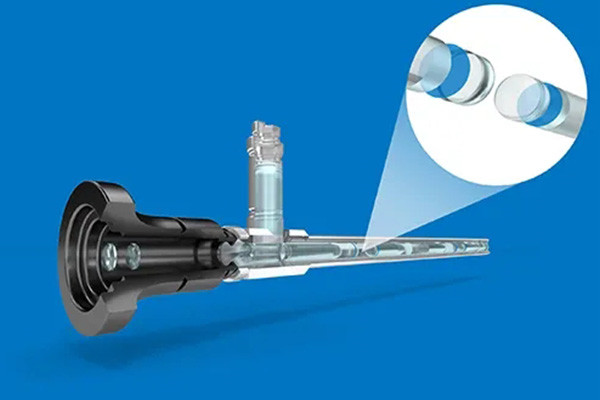

- Optical and Photonic Applications: In optical and photonic systems, such as fiber optics, lenses, and laser assemblies, optically apparent potting compounds are utilized for bonding and encapsulation purposes. These compounds help to minimize light scattering and maintain optical clarity, ensuring optimal performance of the optical components.

- Aerospace and Defense: Optically apparent potting compounds play a critical role in aerospace and defense applications, where high-performance electronic systems require protection against harsh environments, including extreme temperatures, vibration, and moisture. These compounds are used to pot avionics systems, radar equipment, and military displays while maintaining optical clarity for visibility and sensor functionality.

- Automotive Industry: Within the automotive sector, optically apparent potting compounds are utilized for encapsulating electronic control units (ECUs), sensors, and lighting systems. Their ability to withstand automotive environments, including temperature variations and exposure to chemicals, makes them indispensable for ensuring the reliability and longevity of automotive electronics.

Potting compounds’ versatility and optical clarity make them indispensable across various industries, including electronics, renewable energy, healthcare, aerospace, automotive, and telecommunications, where transparent encapsulation and protection of sensitive components are essential requirements.

How do these compounds enhance the performance of LED lighting systems?

Several compounds play crucial roles in enhancing the performance of LED (Light Emitting Diode) lighting systems. When incorporated into LED design and manufacturing processes, these compounds contribute to improved efficiency, longevity, and light quality.

- Phosphors: Phosphors are vital in producing white light in LEDs. When excited by the blue light emitted by the LED chip, phosphors emit light at longer wavelengths, resulting in a mixture of blue and yellow light that appears white to the human eye. Advancements in phosphor technology have led to improvements in the color rendering index (CRI), which measures the accuracy of color reproduction and LEDs’ efficacy. This allows for brighter and more energy-efficient lighting solutions.

- Thermal Interface Materials (TIMs): TIMs are compounds used to improve the thermal management of LEDs. LEDs generate heat during operation; excess heat can degrade performance and reduce lifespan. High-quality TIMs facilitate efficient heat transfer away from the LED chip, ensuring it operates within the optimal temperature range. This enhances performance and longevity by reducing thermal stress on the LED components.

- Encapsulation Materials: Encapsulation materials protect LED chips from environmental factors such as moisture, dust, and mechanical damage. Silicone-based encapsulants are commonly used due to their excellent optical properties, flexibility, and resistance to yellowing over time. These materials ensure LED lighting systems’ long-term reliability and stability, even in harsh operating conditions.

- Substrate Materials: Substrates provide mechanical support and electrical connectivity for LED chips. Materials like aluminum nitride (AlN) and ceramic substrates offer high thermal conductivity, which helps dissipate heat efficiently. This prevents thermal runaway and improves the overall performance and reliability of the LED.

- Doping Agents: Doping agents are used in semiconductor fabrication to alter the electrical properties of materials. Manufacturers can tailor their electrical characteristics by carefully doping the semiconductor layers within an LED, such as forward voltage and efficiency. This allows optimizing LED performance for specific applications, such as high-brightness displays or automotive lighting.

Compounds such as phosphors, TIMs, encapsulation materials, substrate materials, and doping agents enhance the performance of LED lighting systems by improving efficiency, longevity, thermal management, and light quality. Continued advancements in material science and manufacturing techniques are driving further improvements in LED technology, making them increasingly attractive for a wide range of lighting applications.

Are optically clear potting compounds suitable for outdoor applications?

Optically apparent potting compounds are typically formulated to provide excellent clarity, making them ideal for encapsulating and protecting delicate electronic components where visual inspection is necessary. While these compounds offer transparency and aesthetic appeal, their suitability for outdoor applications depends on various factors.

Firstly, it’s essential to consider the environmental conditions to which the potted electronics will be exposed. Outdoor environments can subject materials to various challenges, including UV radiation, temperature fluctuations, moisture, and mechanical stress. Optically apparent potting compounds must resist these elements to maintain clarity and effectively protect the enclosed electronics.

UV stability is a critical consideration for outdoor applications. Prolonged exposure to sunlight can cause yellowing, degradation, or loss of optical clarity in some materials. Optically apparent potting compounds formulated with UV stabilizers can resist yellowing and maintain transparency over time, ensuring long-term performance in outdoor settings.

Furthermore, outdoor applications often involve temperature variations. Optically apparent potting compounds should exhibit a broad operating temperature range to withstand extreme cold and heat without compromising their optical properties or mechanical integrity.

Moisture resistance is another crucial factor. Outdoor environments may expose potted electronics to rain, humidity, or even submersion in water. Optically apparent potting compounds should provide adequate moisture protection to prevent ingress and maintain the integrity of the encapsulated components.

Additionally, mechanical durability is essential for outdoor applications where potted electronics may be subjected to vibrations, impacts, or other mechanical stresses. The potting compound should have sufficient flexibility and adhesion to withstand such forces without cracking or delamination, which could compromise both the protection and optical clarity of the encapsulated components.

Optically apparent potting compounds can be suitable for outdoor applications, provided they are formulated to withstand UV radiation, temperature fluctuations, moisture exposure, and mechanical stress. Manufacturers should carefully evaluate the specific requirements of their outdoor applications and select potting compounds that meet these criteria to ensure optimal performance and longevity.

Do these compounds comply with industry standards and regulations?

To accurately determine whether compounds comply with industry standards and regulations, several factors need consideration, including the specific compounds in question, the industry they are intended for, and the regulatory bodies overseeing that industry. Generally, industries such as pharmaceuticals, food and beverages, cosmetics, and chemicals are heavily regulated to ensure safety, efficacy, and quality.

Firstly, it’s essential to identify the compounds and their intended use. For instance, in pharmaceuticals, active pharmaceutical ingredients (APIs) must adhere to stringent regulations set by authorities like the Food and Drug Administration (FDA) in the United States or the European Medicines Agency (EMA) in the European Union. These regulations encompass purity, stability, and efficacy, as guidelines like Good Manufacturing Practices (GMP) outline.

Similarly, compounds in the food and beverage industry are subject to regulations by agencies like the FDA (in the U.S.) or the European Food Safety Authority (EFSA) in Europe. These regulations cover food additives, preservatives, and contaminants, ensuring products are safe for consumption.

In the cosmetics industry, compounds must comply with regulations set forth by organizations like the FDA (for the U.S. market) or the Cosmetic Ingredient Review (CIR) panel. These regulations focus on ingredient safety, labeling requirements, and restrictions on certain substances.

Chemical compounds’ regulations vary depending on their application. Compounds used in agriculture, for example, are regulated by agencies like the Environmental Protection Agency (EPA) in the U.S., which assesses factors such as environmental impact and human health risks.

Companies typically conduct thorough testing, documentation, and quality control measures throughout the manufacturing process to ensure compliance. This may involve analytical testing, stability studies, and adherence to specific manufacturing protocols.

Compounds’ compliance with industry standards and regulations depends on various factors, including their intended use and the regulatory framework governing that industry. Adherence to these standards is critical to ensuring product safety, efficacy, and legality in the marketplace.

What are the considerations for selecting the suitable optically clear potting compound?

Selecting the appropriate optically clear potting compound involves carefully considering several factors to ensure optimal performance and compatibility with the intended application.

- Optical Clarity: The primary requirement is optical clarity. The potting compound should have minimal coloration, haze, or distortion to ensure it does not interfere with light transmission. This is crucial for applications with essential visibility or light transmission, such as LED lighting or optical sensors.

- Refractive Index: Matching the refractive index of the potting compound to that of the materials it will be in contact with, such as lenses or substrates, helps minimize reflection and refraction at interfaces, thereby maintaining optical clarity and maximizing light transmission.

- Chemical Compatibility: The potting compound must be compatible with the materials it will encapsulate to prevent degradation or discoloration over time. Consider the effects of exposure to heat, moisture, chemicals, and UV radiation, particularly in harsh operating environments.

- Mechanical Properties: Assess the mechanical properties of the potting compound, such as hardness, flexibility, and impact resistance. The chosen material should provide sufficient protection against physical damage while accommodating any thermal expansion or contraction.

- Adhesion: Adequate adhesion to the substrate is essential to ensure long-term stability and prevent delamination or moisture ingress. Consider surface preparation techniques or using primers to promote adhesion if necessary.

- Thermal Conductivity: Depending on the application, thermal conductivity may be critical for dissipating heat generated by components within the encapsulated assembly. Opt for potting compounds with suitable thermal conductivity to prevent overheating and maintain performance.

- Curing Method: Evaluate the curing method of the potting compound—whether it requires heat curing, UV curing, or room-temperature curing. Ensure compatibility with the manufacturing process and equipment available.

- Regulatory Compliance: Verify that the chosen potting compound complies with relevant industry standards and regulations, particularly regarding safety, environmental impact, and electrical insulation properties.

By carefully considering these factors, manufacturers can select the most suitable optically clear potting compound to meet the specific requirements of their application while ensuring durability, reliability, and performance.

How do optically apparent potting compounds contribute to product aesthetics?

Optically apparent potting compounds are crucial in enhancing product aesthetics across various industries. These compounds, often made of transparent resins like epoxy or silicone, offer several key benefits that contribute to the overall visual appeal of a product.

First and foremost, optically apparent potting compounds provide a pristine, glass-like finish that allows for maximum visibility of internal components. Whether used in electronics, automotive parts, lighting fixtures, or decorative items, these compounds’ transparency ensures that intricate designs, branding elements, and other details remain visible to the user. This transparency creates a sense of sophistication and modernity, elevating the product’s perceived quality.

Furthermore, optically apparent potting compounds offer exceptional clarity and light transmission properties. They allow light to pass through with minimal distortion, resulting in bright, vibrant displays and illuminated features. In applications such as LED lighting or electronic displays, this clarity enhances visibility and ensures that colors appear true to life, creating an engaging visual experience for the end user.

Moreover, these compounds provide a protective barrier for sensitive electronic components or delicate assemblies without sacrificing aesthetics. By encapsulating internal parts in a clear resin, manufacturers can safeguard against moisture, dust, and other environmental factors without obstructing the view of the components. This not only enhances the product’s durability and reliability but also maintains its sleek appearance over time.

Additionally, optically apparent potting compounds offer versatility in design, allowing for complex shapes, intricate patterns, and custom finishes. Manufacturers can incorporate unique textures, embedded objects, or decorative elements into the resin, further enhancing the visual appeal of the finished product. Whether creating a futuristic electronic device or a high-end decorative item, these compounds provide endless possibilities for creative expression.

Optically apparent potting compounds contribute to product aesthetics by providing transparency, clarity, and protection without compromising design integrity. By enhancing visibility, optimizing light transmission, and enabling creative freedom, these compounds elevate the overall visual appeal of products across various industries, ultimately improving the user experience and brand perception.

Can optically clear potting compounds be easily removed or reworked?

Optically apparent potting compounds, often used in electronics and optical applications, protect while maintaining optical clarity. However, their removal or reworkability depends on several factors, including the specific compound used, the application, and the desired outcome.

Optically apparent potting compounds are generally formulated to provide excellent adhesion to substrates, making them challenging to remove. Many of these compounds cure to form strong bonds with surfaces, ensuring stability and protection. Their chemical composition typically includes resins such as epoxies or silicones, contributing to their durability and optical clarity.

Removing or reworking optically clear potting compounds usually involves specialized techniques and tools. Mechanical methods like scraping or grinding may damage delicate components or substrates, making them unsuitable for many applications. Chemical solvents can be effective, but they may also affect the potted materials or require careful handling due to their toxicity and environmental impact.

Some optically clear potting compounds are designed to be reworkable, allowing for easier removal or adjustment without causing damage. These formulations often incorporate additives or modifiers that facilitate disassembly or reworking processes. However, reworkable compounds may sacrifice properties like adhesion strength or optical clarity compared to their non-reworkable counterparts.

In some instances, thermal methods such as heating or freezing can weaken the bond of the potting compound, making it easier to remove. However, these methods require precise control to avoid damaging sensitive components or substrates.

Ultimately, the ease of removal or reworkability of optically clear potting compounds depends on the specific requirements of the application and the properties of the compound itself. While some compounds may be more challenging to remove due to their strong adhesion and curing properties, others may offer reworkability options for applications that require flexibility or adjustments during assembly or maintenance. It’s crucial to carefully consider these factors when selecting a potting compound for a particular application to ensure optimal performance and ease of handling.

What are the environmental implications of using optically clear potting compounds?

Optically apparent potting compounds offer advantages in various industries, especially electronics, providing protection, insulation, and optical clarity for sensitive components. However, their use also brings environmental implications that warrant consideration.

- Chemical Composition: Optically clear potting compounds often contain synthetic polymers and resins like epoxy or silicone. These materials may include additives like plasticizers, fillers, and curing agents. Some of these additives, particularly certain plasticizers and curing agents, can be toxic or environmentally harmful if released into the environment.

- Manufacturing Process: The production of optically clear potting compounds involves energy-intensive processes and may generate waste, emissions, and pollutants. Chemical synthesis and refining of raw materials contribute to greenhouse gas emissions and other forms of pollution. Additionally, the disposal of manufacturing byproducts can pose environmental risks if not managed properly.

- End-of-Life Disposal: Disposal at the end of the product lifecycle presents challenges. Optically apparent potting compounds may not be easily recyclable due to their complex composition and the challenges of separating them from other materials in electronic devices. Improper disposal, such as landfilling or incineration, can release harmful substances into the environment, potentially contaminating soil, water, and air.

- Longevity and Durability: While optically clear potting compounds protect electronic components, their longevity and durability can lead to concerns. If electronic devices encapsulated with these compounds are discarded or obsolete, the compounds may persist in the environment for long periods without degrading, contributing to electronic waste accumulation.

- Alternatives and Sustainable Practices: Addressing the environmental implications of optically clear potting compounds requires exploring alternative materials and sustainable practices. This may involve the development of bio-based or biodegradable alternatives, improving recycling technologies for electronic components, and implementing eco-friendly manufacturing processes to reduce environmental impact.

While optically clear potting compounds offer valuable benefits for electronic applications, their use raises environmental concerns related to chemical composition, manufacturing processes, end-of-life disposal, and longevity. Addressing these implications requires a concerted effort from manufacturers, regulators, and consumers to adopt more sustainable practices and develop environmentally friendly alternatives.

Are there any emerging trends or innovations in the development of these compounds?

These compounds, such as electronic devices, LED lighting, and optical sensors, are commonly used in applications where transparency and optical clarity are essential. Some of the trends and innovations in this field include:

- Improved Optical Clarity: Researchers and manufacturers continuously improve the optical clarity of OCPCs to meet the growing demand for high-quality transparent materials in various industries. This involves developing new formulations and manufacturing processes that minimize the presence of impurities and bubbles, resulting in more transparent materials.

- Enhanced UV Stability: UV stability is crucial for OCPCs in outdoor applications or environments exposed to sunlight. Innovations focus on formulating compounds with improved UV stability to prevent yellowing or degradation over time, thus extending the lifespan of optical components.

- Thermal Management: Effective thermal management is essential for many electronic devices and LED lighting applications. Innovations in OCPCs involve incorporating materials with high thermal conductivity to dissipate heat efficiently while maintaining optical clarity. This helps prevent overheating and extend the lifespan of electronic components.

- Customization and Specialty Applications: There’s a growing demand for OCPCs tailored to specific applications and requirements. Manufacturers offer customizable formulations to meet the unique needs of different industries, such as aerospace, automotive, and medical devices. Specialty OCPCs may have properties like biocompatibility, flame retardancy, or resistance to harsh chemicals.

- Low Shrinkage Formulations: Shrinkage during curing can lead to stress build-up and optical distortion in transparent materials. Innovations aim to develop OCPC formulations with minimal shrinkage during curing, ensuring dimensional stability and optical clarity.

- Environmental Considerations: With increasing emphasis on sustainability, there’s a trend towards developing OCPCs with reduced environmental impact. This includes using renewable or bio-based raw materials and formulating compounds that are recyclable or biodegradable.

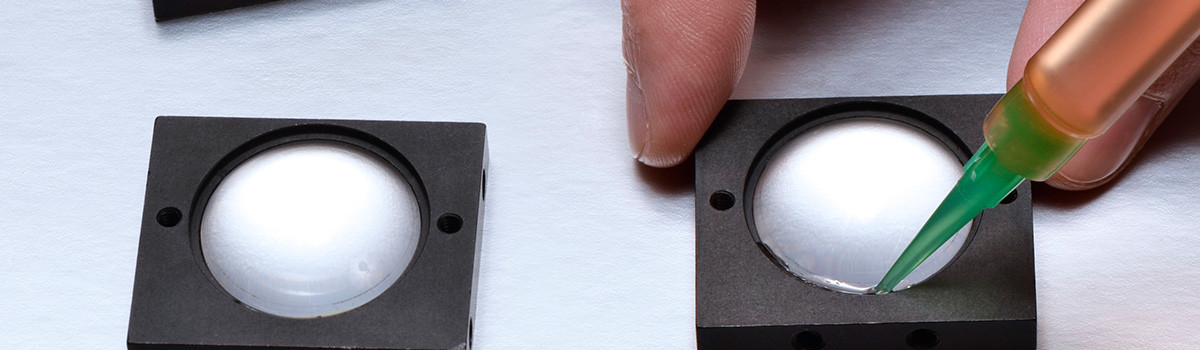

- Improved Dispensing and Processing: Advances in dispensing and processing technologies enable more precise application of OCPCs, reducing waste and improving efficiency in manufacturing processes. This includes developments in automated dispensing systems, enhanced flow properties of compounds, and optimized curing processes.

These trends and innovations reflect the ongoing efforts to enhance the performance, reliability, and versatility of Optically Clear Potting Compounds to meet the evolving needs of various industries. For the latest developments beyond my last update, it’s advisable to consult recent literature, industry reports, and technical conferences in materials science and engineering.

Conclusion:

Optically apparent potting compounds offer a unique blend of optical transparency and protective properties, making them indispensable in various electronics, automotive, and aerospace industries. Their ability to provide optical clarity while safeguarding delicate components against environmental hazards makes them a preferred choice for designers and engineers. As technology advances and new applications emerge, the demand for optically clear potting compounds is expected to grow, driving further innovation in this field.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

Potting Compound for PCB

Potting Compound for PCB A potting compound is a liquid or semi-liquid material that is poured or injected over a PCB or electronic assembly, then

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds Electronic potting compounds play a vital role in the electronics industry. They can

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices In modern industrial manufacturing, encapsulating materials are widely used in numerous

A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies In the field of electronic manufacturing, the encapsulation process of printed

Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation During the operation of electronic devices, the PCB (Printed Circuit

A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs In modern electronic devices, the printed circuit board (PCB) plays a central