Home > Potting Compound > LED Potting Compound

LED Potting Compound

In the realm of electronic applications, LED potting compound plays a crucial role in ensuring the durability, efficiency, and reliability of LED devices. This specialized compound provides protection against environmental factors, thermal stress, and mechanical damage, thereby extending the lifespan of LEDs and enhancing their performance. Let’s delve deeper into the various facets of LED potting compound and understand its significance in electronic engineering.

Table of Contents

ToggleWhat is LED potting compound, and how does it differ from traditional potting materials?

The LED potting compound is a specialized material crucial in manufacturing LED lighting systems. LEDs have grown in popularity because of their lifetime and energy efficiency as the demand for energy-efficient lighting solutions rises. However, ensuring the durability and reliability of LED fixtures requires careful consideration of their internal components, including the potting compound.

In contrast to conventional potting materials, LED potting compounds are specially made to satisfy the particular needs of LED applications. These compounds serve several essential functions, including encapsulating sensitive electronic components, providing thermal management, and enhancing mechanical stability.

One primary difference between LED potting compounds and conventional potting materials is their thermal conductivity properties. LED potting compounds are engineered to efficiently dissipate heat generated by LED components, ensuring optimal performance and extending the lifespan of the lighting system. It is essential in high-power LED applications, where efficient heat dissipation is crucial.

Moreover, LED potting compounds offer superior adhesion to various substrates commonly used in LED manufacturing, such as metals, ceramics, and plastics. Strong adhesion ensures dependable performance even in challenging circumstances by shielding sensitive components from outside elements, including vibration, moisture, and dust.

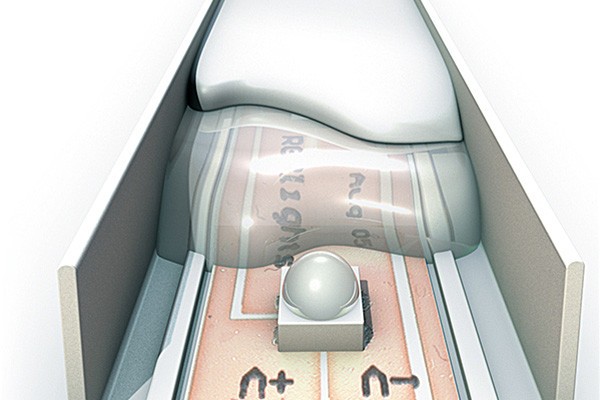

Another distinguishing feature of LED potting compounds is their optical clarity. Unlike opaque conventional potting materials, LED potting compounds are often transparent or translucent, allowing light to be transmitted without compromising the integrity of the encapsulated components. This optical clarity is essential in maintaining LED fixtures’ brightness and color consistency, making them ideal for applications where aesthetics are important.

Furthermore, LED potting compounds exhibit excellent chemical resistance, protecting the internal electronics from corrosive substances and environmental contaminants. This resistance enhances the longevity of LED lighting systems, reducing maintenance costs and downtime associated with component failure.

Why is LED potting compound essential for protecting electronic components?

In the realm of electronics, particularly in the domain of LED lighting, the utilization of LED potting compounds is becoming increasingly indispensable. This specialized compound is crucial in safeguarding electronic components, ensuring their longevity, durability, and optimal performance. Let’s delve into why LED potting compound is essential for protecting electronic components:

Environmental Protection:

- LED potting compounds create a protective barrier around electronic components, shielding them from harsh environmental elements such as moisture, dust, and chemicals.

- They prolong the components’ lifespan by preventing oxidation, corrosion, and other damage that may result from exposure to these elements.

Mechanical Stability:

- These compounds offer excellent mechanical stability, providing structural support to delicate electronic parts.

- They absorb vibrations and shocks, reducing the risk of physical damage caused by external impacts or rough handling.

Thermal Management:

- LED potting compounds have excellent thermal conductivity properties, effectively dissipating heat from electronic components.

- Maintaining optimal operating temperatures prevents overheating, which can lead to performance degradation and even component failure.

Electrical Insulation:

- Ensuring electrical insulation is crucial for preventing short circuits and electrical malfunctions.

- LED potting compounds act as insulators, effectively isolating electronic components and external conductive materials from each other.

Chemical Resistance:

- These compounds exhibit high resistance to various chemicals, solvents, and oils, making them ideal for applications in challenging environments.

- They protect electronic components from chemical corrosion and degradation, ensuring consistent performance.

UV Stability:

- LED potting compounds offer UV stability, preventing degradation or discoloration of the encapsulated components when exposed to sunlight or other UV sources.

How does LED potting compound contribute to thermal management in LEDs?

In LED technology, optimal thermal management is paramount for longevity, efficiency, and reliability. One of the critical components in achieving this crucial task is the LED potting compound. This particular substance is essential for protecting LEDs from heat-related problems, which extends their lifespan and improves performance. Let’s delve into how LED potting compound contributes significantly to thermal management in LEDs:

- Heat Dissipation:LED potting compound possesses excellent thermal conductivity properties. EncapsulatingEncapsulating the LED components facilitates efficient heat transfer away from sensitive electronic parts. It prevents overheating and ensures consistent performance even under demanding conditions.

- Enhanced Stability:The application of the LED potting compound forms a shield that shields the LED assembly from environmental factors like dust, moisture, and vibrations. This insulation not only maintains the LED’s structural integrity but also prevents internal components from degrading due to thermal cycling.

- Improved Durability:LEDs subjected to harsh operating conditions are susceptible to premature failure. However, the potting compound protects against thermal stresses, mechanical shocks, and chemical exposure. By significantly extending the lifespan of LEDs, this process reduces maintenance costs and enhances reliability.

- Customized Solutions:LED potting compounds are available in various formulations to suit specific application requirements. Whether it’s high-temperature environments, outdoor installations, or underwater applications, there’s a potting compound tailored to meet diverse needs. Manufacturers can choose from different viscosity levels, curing times, and thermal conductivity ratings to optimize performance.

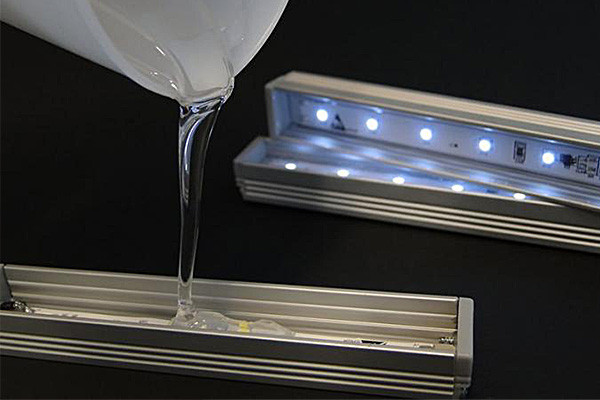

- Ease of Application:Applying LED potting compounds is simple and may be easily incorporated into current manufacturing processes. Whether through manual or automated dispensing systems, the compound can be accurately deposited to encapsulate LEDs efficiently.

What are the primary components of LED potting compound?

LED potting compound prolongs life and improves the performance of LED components by shielding them from external influences. Let’s delve into the primary elements that make up this essential material:

Epoxy Resin

- Epoxy resin serves as the primary matrix of LED potting compounds.

- It offers excellent adhesion to various surfaces, ensuring a secure encapsulation of LED components.

- Epoxy resin provides insulation, protecting LEDs from moisture, dust, and other contaminants.

Hardeners

- Hardeners are added to epoxy resin to catalyze the curing process, transforming the liquid resin into a solid material.

- They determine the potting compound’s curing time and mechanical properties, such as hardness and flexibility.

- Proper selection of hardeners is critical to achieving desired performance characteristics.

Fillers

- Fillers are incorporated into LED potting compounds to modify their properties and reduce costs.

- Joint fillers include silica, alumina, and various mineral powders.

- They enhance thermal conductivity, improve mechanical strength, and reduce shrinkage during curing.

Additives

- Additives impart specific properties to LED potting compounds, enhancing their performance in various applications.

- UV stabilizers protect against degradation caused by exposure to ultraviolet radiation.

- Flame retardants increase the material’s resistance to combustion, ensuring safety in potential fire hazards.

- Anti-oxidants prevent oxidation and degradation of the potting compound over time, prolonging its lifespan.

Colorants

- Colorants are added for aesthetic purposes or to differentiate between different formulations.

- They do not significantly affect the performance of the potting compound but may influence its UV stability or thermal conductivity.

Benefits of LED Potting Compound:

- Protection:Shields LED components from moisture, dust, and mechanical damage.

- Enhanced Performance:Improves thermal management, prolonging LED lifespan and maintaining optimal performance.

- Versatility: Can be customized with various additives and fillers to meet specific application requirements.

- Reliability: Ensures consistent performance even in harsh environments, contributing to the reliability of LED-based products.

How does LED potting compound enhance the waterproofing capabilities of LED devices?

LED devices are renowned for their energy efficiency, durability, and versatility, making them ubiquitous in various automotive and consumer electronics industries. However, effective waterproofing is crucial to ensure their longevity and performance in harsh environments. One method that significantly enhances the waterproofing capabilities of LED devices is using an LED potting compound.

What is an LED Potting Compound?

- The LED potting compound is a specialized material designed to encapsulate and protect electronic components, mainly LEDs, from environmental factors such as moisture, dust, and vibration.

- Composed of various polymers such as silicone, epoxy, or urethane, LED potting compounds provide a robust barrier against water ingress while maintaining thermal conductivity.

Enhanced Waterproofing Capabilities:

- Sealing and Encapsulation:The LED potting compound creates a seamless barrier around the LED components, sealing them from moisture and other contaminants. It prevents corrosion, short circuits, and performance degradation caused by exposure to water.

- Improved Mechanical Protection:LED potting compound provides encapsulation that shields against water and enhances mechanical durability. It protects LEDs from physical damage due to shock, vibration, or rough handling, extending their lifespan.

- Thermal Management:Despite being waterproof, LED potting compounds also facilitate heat dissipation, which is crucial for maintaining optimal LED performance. They transfer heat away from the LED components, preventing overheating and ensuring consistent operation even in demanding conditions.

Applications:

- Outdoor Lighting:LED potting compound is widely used in outdoor lighting fixtures such as streetlights, floodlights, and garden lights, where exposure to moisture and varying temperatures is common.

- Automotive Lighting:In automotive applications, LED potting compound ensures the longevity of headlights, taillights, and interior lighting, even in challenging environments like underbody lighting where water and debris exposure is high.

- Marine and Aerospace:LED potting compound is found in marine and aerospace lighting applications, where water resistance and durability are paramount due to exposure to saltwater, humidity, and extreme temperatures.

Can LED potting compound withstand extreme temperature variations?

LED potting compound is a specialized material that encapsulates LED components, providing insulation and protection from moisture, mechanical shock, and thermal stress.

Key Factors in Evaluating Temperature Resistance:

- Thermal Conductivity:Efficient dissipation of heat generated by LEDs is essential for optimal performance and longevity.

- Coefficient of Thermal Expansion (CTE): Matching the coefficient of thermal expansion (CTE) with LED materials is crucial to prevent stress-induced damage.

- Operating Temperature Range:Ability to function within a specified temperature range.

Factors Influencing Temperature Resistance:

- Composition:Silicones, epoxies, and polyurethanes are common materials used in LED potting compounds, each with varying thermal properties.

- Fillers:Adding thermally conductive fillers like ceramics or metals enhances heat dissipation.

- Curing Process:Proper curing ensures the compound can withstand temperature fluctuations without degrading.

Benefits of Temperature Resistance:

- Extended Lifespan:Resisting temperature extremes prevent premature failure of LED components.

- Reliability:Ensures consistent performance under diverse environmental conditions.

- Reduced Maintenance:Minimizes the need for frequent replacements or repairs due to temperature-induced damage.

Challenges and Solutions:

- Thermal Cycling:Rapid temperature changes can lead to expansion and contraction, potentially causing delamination or cracking. Solutions include optimizing CTE or using flexible formulations.

- High-Temperature Environments:Applications in hot climates or near heat sources require compounds with superior heat resistance, often achieved through advanced formulations or fillers.

How does LED potting compound prevent moisture ingress in electronic assemblies?

The LED potting compound is crucial in safeguarding electronic assemblies from the detrimental effects of moisture ingress. As the demand for compact and efficient electronic devices continues to rise, manufacturers are increasingly turning to advanced materials like potting compounds to enhance the durability and reliability of their products.

Moisture ingress poses a significant threat to electronic components, leading to corrosion, short circuits, and, ultimately, device failure. Sensitive components like LEDs, often exposed to harsh environmental conditions, exemplify this challenge. However, applying LED potting compound provides a robust solution to this problem.

One of the primary functions of LED potting compounds is to create a protective barrier around electronic assemblies, sealing them off from external elements, including moisture, dust, and chemicals. Encapsulation achieves this by carefully pouring or injecting the potting compound around the components, forming a solid, waterproof layer.

The key to the effectiveness of LED potting compounds lies in their unique properties. These substances are designed to offer superior adhesion to various substrates while preserving their flexibility and thermal stability. It ensures the encapsulated components remain securely sealed and protected even under extreme conditions.

Furthermore, LED potting compounds are engineered to have low permeability to moisture, preventing water molecules from penetrating the encapsulated area. Preserving the integrity of electronic assemblies is essential, particularly in applications where prolonged exposure to moisture is unavoidable.

In addition to moisture resistance, LED potting compounds offer thermal conductivity properties, helping dissipate heat generated by the electronic components. Maintaining optimal operating temperatures and prolonging the lifespan of the devices are crucial goals to achieve.

Moreover, LED potting compounds come in different formulations to suit specific application requirements. Whether for outdoor lighting fixtures, automotive electronics, or industrial equipment, manufacturers can choose the appropriate potting compound that offers the desired level of protection and performance.

What role does LED potting compound play in reducing vibration-induced damage?

In electronics, especially in LED lighting, protecting delicate components from external factors is paramount. One such protective measure gaining prominence is the utilization of LED potting compounds. These compounds serve a crucial role in reducing vibration-induced damage, ensuring the longevity and reliability of LED systems.

Understanding LED Potting Compound:

- Composition:LED potting compounds typically consist of resins, hardeners, and additives designed to create a robust, protective layer around the LED assembly.

- Properties:These compounds possess excellent adhesion properties, allowing them to form a strong bond with the LED components, effectively encapsulating and shielding them from external stressors.

- Application:LED potting compounds are applied in liquid form, allowing them to flow around and encase the delicate electronic components before curing into a solid, protective layer.

Mitigating Vibration-Induced Damage:

- Shock Absorption:LED potting compounds act as a buffer, absorbing and dispersing the energy generated by vibrations, thus preventing it from reaching the sensitive LED components.

- Dampening Effect:By dampening vibrations, potting compounds minimize the oscillations experienced by LEDs, reducing the likelihood of mechanical failure or dislodgment of solder joints.

- Enhanced Reliability: Potting compounds significantly enhance the reliability of LED systems, particularly in applications prone to high levels of vibration, such as automotive lighting or outdoor signage.

Benefits of LED Potting Compounds:

- Extended Lifespan:By shielding LEDs from vibration-induced stress, potting compounds contribute to an extended operational lifespan, reducing the frequency of maintenance and replacement.

- Improved Performance:The stability provided by potting compounds ensures consistent performance of LEDs, maintaining brightness levels and color accuracy over time.

- Environmental Protection:LED potting compounds resist moisture, dust, and other environmental contaminants, safeguarding internal electronics from corrosion and degradation.

How does LED potting compound facilitate ease of assembly during manufacturing?

In LED manufacturing, efficiency is key to meeting the growing demand for energy-efficient lighting solutions. LED potting compound emerges as a critical facilitator in streamlining the assembly process, offering numerous benefits contributing to ease of manufacturing. Let’s explore how LED potting compound enhances assembly efficiency:

- Encapsulation Simplification:LED potting compound is a versatile encapsulation material that simplifies the assembly of LED components. EncapsulatingEncapsulating delicate electronic parts such as LED chips, drivers, and circuitry eliminates the need for intricate assembly steps, reducing the overall complexity of the manufacturing process.

- Protection and Insulation:LEDs are exposed to various environmental factors that can compromise their performance and longevity during assembly. LED potting compound provides a protective barrier, shielding components from moisture, dust, corrosion, and mechanical stress. LEDs are subjected to various environmental conditions during construction that may impair their longevity and performance.

- Enhanced Structural Integrity:Applying LED potting compounds reinforces the structural integrity of LED modules and luminaires. Securely bonding components together prevents loosening or misalignment, ensuring uniformity and consistency in the assembly. It results in robust, reliable LED products that meet stringent quality standards.

- Customized Formulations:LED potting compounds are available in various formulations tailored to specific manufacturing requirements. Manufacturers can choose from different viscosity levels, cure times, and thermal conductivity ratings to optimize performance and compatibility with their assembly processes. This customization ensures seamless integration into existing workflows without compromising efficiency.

- Facilitated Dispensing:Dispensing LED potting compounds can be easily integrated into automated assembly systems, enabling precise and uniform application. Whether through manual or automated dispensing techniques, the potting compound can be accurately deposited to encapsulate LEDs efficiently. It reduces assembly time and minimizes material waste, contributing to cost savings and increased productivity.

What are the key considerations for selecting the right LED potting compound?

LED potting compounds protect LEDs from environmental factors such as moisture, temperature fluctuations, and physical damage. Choosing a suitable compound is essential to ensure optimal performance and longevity of LED devices. Here are some key considerations to keep in mind when selecting an LED potting compound:

- Thermal Conductivity: To effectively dissipate heat produced by the LED, avoid overheating, and extend its lifespan, use a potting compound with good thermal conductivity.

- Chemical Compatibility: Ensure compatibility between the potting compound and other materials used in the LED assembly to avoid chemical reactions that could compromise performance or lead to failure.

- Optical Clarity: For applications where light transmission is crucial, such as in outdoor lighting or signage, select a potting compound with excellent optical clarity to maintain brightness and visibility.

- UV Stability: LEDs exposed to outdoor environments are susceptible to degradation from UV radiation. Choose a potting compound with UV stabilizers to prevent yellowing or deterioration of the material over time.

- Flexibility vs. Rigidity: Consider the mechanical properties required for your application. Flexible potting compounds are suitable for applications where vibration or movement is expected, while rigid compounds provide better protection against physical impacts.

- Curing Time and Method: Evaluate the curing time and method of the potting compound to ensure compatibility with your manufacturing process and production timeline.

- Environmental Resistance: Examine the potting compound’s resilience to external elements, including dampness, chemicals, and high or low temperatures, to guarantee long-term dependability under varied operating circumstances.

- Ease of Application: Choose a potting compound that is easy to handle and apply, whether by dispensing equipment or manual processes, to streamline manufacturing and reduce labor costs.

By carefully considering these factors, manufacturers can select the most suitable LED potting compound for their specific application, ensuring optimal performance, durability, and reliability of LED devices in various operating environments.

How does LED potting compound affect the optical properties of LEDs?

LED potting compound, also known as encapsulant, is a material used to protect and enhance the performance of LEDs. It surrounds the LED chip, providing mechanical support, thermal management, and protection against environmental factors such as moisture, dust, and vibration.

Impact on Optical Properties:

The choice of potting compound significantly affects the optical properties of LEDs, including brightness, color consistency, and light distribution. Here’s how:

- Refractive Index:LED potting compounds matching refractive indices to the LED chip material help minimize light loss at the interface. It ensures efficient light transmission and enhances brightness.

- Color Rendering: The transparency and color stability of the potting compound influence the LED’s color rendering index (CRI). High-quality potting materials maintain color consistency and prevent discoloration over time, preserving the LED’s ability to render accurate colors.

- Light Diffusion:Some potting compounds are designed to scatter or diffuse light evenly, reducing hotspots and glare. It improves illumination uniformity and enhances visual comfort, particularly in applications where soft, diffused light is desired.

- Thermal Management:Efficient thermal management maintains LED performance and longevity. Certain potting compounds possess excellent thermal conductivity, dissipating heat away from the LED chip and ensuring stable operation at optimal temperatures. It indirectly influences optical properties by preventing the thermal degradation of materials.

- UV Stability: Exposure to UV radiation can degrade the optical properties of LEDs over time. UV-stable potting compounds shield the LED from UV damage, preserving its optical clarity and preventing the yellowing or hazing of encapsulant materials.

Choosing the Right Potting Compound:

Selecting the appropriate potting compound involves considering various factors, including:

- Application requirements (indoor/outdoor, harsh environments)

- Thermal conductivity and heat dissipation

- Optical transparency and color stability

- Chemical resistance and environmental durability

Can LED potting compound be customized for specific application requirements?

In the dynamic landscape of LED technology, versatility and adaptability are paramount. LED potting compound emerges as a versatile solution, offering the flexibility to be customized for specific application requirements. Let’s delve into the realm of customization and explore the possibilities of tailoring LED potting compound:

- Formulation Flexibility:LED potting compounds come in diverse formulations, allowing for precise customization to meet the unique needs of various applications. Manufacturers can adjust parameters such as viscosity, curing time, and thermal conductivity to achieve optimal performance in specific environments.

- Temperature Extremes:Different applications may demand LED lighting solutions that operate in extreme temperatures, whether in high-temperature industrial settings or freezing outdoor environments. LED potting compounds can be customized to withstand these temperature extremes, ensuring consistent performance and reliability.

- Chemical Resistance:Certain applications expose LED components to harsh chemicals, solvents, or corrosive substances. Customized potting compounds can be formulated with enhanced chemical resistance properties, protecting LEDs from degradation and ensuring longevity even in chemically challenging environments.

- Mechanical Protection:In rugged industrial environments or outdoor installations, LEDs are subjected to mechanical stress, vibrations, and impacts. Tailored potting compounds can provide superior mechanical protection, reinforcing the structural integrity of LED assemblies and minimizing the risk of damage due to handling or environmental factors.

- Waterproofing and Environmental Sealing:Outdoor LED lighting fixtures, automotive lighting, and underwater applications require effective waterproofing and environmental sealing to prevent moisture ingress and ensure long-term reliability. Customized potting compounds can be engineered with advanced waterproofing capabilities, creating a robust barrier against moisture and environmental contaminants.

- Specialized Applications:Some niche applications may have unique requirements that demand specialized solutions. Whether it’s aerospace, medical devices, or marine lighting, LED potting compounds can be customized to meet these specialized industries’ stringent standards and performance criteria.

What are the environmental benefits of using LED potting compound?

Industries are pivoting towards sustainable practices in a world increasingly aware of its environmental footprint. One such advancement is using LED potting compounds, revolutionizing manufacturing processes and end-product sustainability. Let’s delve into the environmental benefits associated with this innovative material:

Reduced Waste Generation:

- LED potting compound facilitates efficient encapsulation of electronic components, minimizing material wastage during production.

- Its precise application ensures minimal excess, optimizing resource utilization and reducing overall waste generation.

Enhanced Durability and Lifespan:

- LED potting compounds extend the lifespan of electronic devices by providing robust protection against environmental factors such as moisture, dust, and vibration.

- This longevity diminishes the frequency of replacements, thereby curbing the accumulation of electronic waste in landfills.

Energy Efficiency:

- LED potting compounds play a pivotal role in enhancing the energy efficiency of LED lighting systems.

- By effectively dissipating heat and preventing thermal degradation, these compounds contribute to energy conservation efforts, aligning with global sustainability goals.

Non-Toxic Formulations:

- Many modern LED potting compounds are formulated with non-toxic materials, reducing environmental hazards during production and disposal.

- This eco-friendly composition mitigates the release of harmful substances into the environment, fostering safer working conditions and minimizing ecological impact.

Recyclability and Reusability:

- Specific formulations of LED potting compounds are designed for easy disassembly and material recovery, facilitating recycling.

- Components encapsulated with these compounds can be efficiently refurbished or repurposed, promoting circular economy principles and conserving valuable resources.

Eco-Friendly Manufacturing Processes:

- The production of LED potting compounds often involves eco-conscious practices such as solvent-free formulations and energy-efficient manufacturing techniques.

- These sustainable approaches reduce carbon emissions and contribute to the conservation of natural resources.

Regulatory Compliance:

- Compliance with these requirements demonstrates manufacturers’ dedication to good business operations and environmental care.

How does LED potting compound improve the reliability of electronic devices in harsh environments?

LED potting compound plays a pivotal role in enhancing the reliability of electronic devices, especially in harsh environments where exposure to moisture, temperature fluctuations, and mechanical stress can compromise their performance. This specialized compound provides a protective barrier around delicate electronic components, safeguarding them from various environmental factors and ensuring uninterrupted operation even under adverse conditions.

One critical way LED potting compound improves the reliability of electronic devices is by offering superior moisture resistance. Moisture ingress can lead to corrosion, short circuits, and electrical failures, particularly in outdoor or industrial settings where humidity levels are high. LED potting compounds form a waterproof seal around electronic assemblies, preventing moisture from seeping into sensitive areas and causing damage. This moisture resistance is essential for maintaining the functionality and longevity of electronic devices, even in damp or humid environments.

Additionally, LED potting compounds provide excellent thermal management properties, crucial for electronic devices operating in environments with elevated temperatures. High temperatures can accelerate component degradation and reduce the lifespan of electronic devices. LED potting compounds help dissipate heat generated by electronic components, preventing overheating and ensuring optimal performance over time. By efficiently transferring heat away from critical components, these compounds contribute to the reliability and stability of electronic devices, even in environments where temperature fluctuations are typical.

Furthermore, LED potting compounds offer mechanical protection, shielding electronic components from physical impact, vibration, and shock. In rugged industrial environments or applications subjected to constant movement or handling, electronic devices are susceptible to mechanical stress, which can lead to component failure or damage. The encapsulating properties of LED potting compounds help absorb shocks and vibrations, reducing the risk of physical harm and enhancing the overall robustness of electronic assemblies.

Another way LED potting compound enhances reliability is by providing chemical resistance against corrosive substances commonly found in industrial or outdoor environments. Exposure to chemicals can corrode electronic components, leading to malfunctions or failure. LED potting compounds act as a barrier against corrosive agents, ensuring the integrity of the internal electronics and prolonging the service life of electronic devices operating in chemically aggressive environments.

What testing procedures are conducted to ensure the quality of LED potting compound?

The LED potting compound protects LED components from environmental factors while ensuring optimal performance. Rigorous testing procedures are conducted to ensure the highest quality of these compounds. Here’s a breakdown of the key testing procedures:

Material Compatibility Testing:

- Evaluate the compatibility of the potting compound with LED materials to prevent any chemical reactions or degradation over time.

- Conduct tests for thermal expansion coefficients to ensure compatibility with different materials.

Electrical Insulation Testing:

- Test the compound’s ability to insulate electrical components effectively.

- Assess dielectric strength to ensure it meets required electrical safety standards.

- Verify resistance to electrical breakdown under varying conditions.

Thermal Conductivity Testing:

- Measure thermal conductivity to ensure efficient dissipation of heat from LED components.

- Conduct tests under different temperature and humidity conditions to simulate real-world usage.

Mechanical Properties Testing:

- Evaluate the compound’s tensile strength, elongation, and flexibility to withstand mechanical stress and vibrations.

- Assess impact resistance to guarantee protection against accidental damage.

Environmental Testing:

- Subject the compound to environmental stress testing, including exposure to UV radiation, moisture, and temperature cycling.

- Evaluate resistance to chemicals, such as solvents and corrosive substances, to ensure longevity in harsh environments.

Aging Tests:

- Conduct accelerated aging tests to simulate long-term exposure to environmental factors.

- Monitor changes in physical, electrical, and thermal properties over time to predict product lifespan.

Adhesion Testing:

- Assess the bond strength between the potting compound and LED components or housing materials.

- Evaluate resistance to delamination or peeling under different conditions.

Quality Control Checks:

- Implement strict quality control checks throughout manufacturing to maintain consistency and reliability.

- Perform batch testing to verify conformity to specifications and standards.

How does LED potting compound mitigate the risks of electrical short circuits?

LED potting compound, a specialized material used in the electronics industry, is crucial in mitigating the risks associated with electrical short circuits. Here’s a breakdown of how this compound effectively safeguards electronic devices:

- Insulation:LED potting compound is a robust insulator, creating a protective barrier around delicate electronic components. Encapsulating the circuitry prevents exposure to moisture, dust, and other environmental factors that could lead to short circuits.

- Sealing Properties:One of the primary functions of LED potting compounds is to seal electronic assemblies, ensuring no gaps or openings are left vulnerable. This tight seal prevents contaminants from ingress, which could compromise the integrity of the circuitry and cause short circuits.

- Thermal Management:LED lighting systems generate heat during operation, which can exacerbate the risk of electrical failures if not properly managed. Specific formulations of LED potting compounds are designed to dissipate heat efficiently, helping to maintain optimal operating temperatures and reducing the likelihood of short circuits due to overheating.

- Vibration Resistance:In applications where electronic devices are subject to vibration or mechanical stress, such as automotive or aerospace environments, LED potting compound provides crucial mechanical support. Securely anchoring components minimizes the risk of loose internal connections and causing short circuits.

- Chemical Resistance:LED potting compounds are engineered to resist various chemicals, including solvents, fuels, and cleaning agents. This chemical resistance ensures that the encapsulated electronics remain protected even in harsh industrial or outdoor settings where exposure to corrosive substances is a concern.

- Electrical Isolation:By encapsulating individual components within a homogeneous matrix, LED potting compound effectively isolates them from each other electrically. This isolation reduces the likelihood of unintended electrical contact or arcing, which can lead to short circuits and potentially catastrophic failures.

What role does LED potting compound play in prolonging the lifespan of LEDs?

The LED potting compound is vital in extending the lifespan of Light Emitting Diodes (LEDs), offering a protective shield against various environmental stressors. Because of its energy efficiency and resilience, LED technology is still ruling the lighting market. As a result, potting compounds play a crucial role in guaranteeing the dependability and lifetime of LED-based products.

At the core of the LED potting compound’s function is its ability to provide robust encapsulation for delicate LED components. LEDs are susceptible to external factors such as moisture, dust, vibration, and temperature fluctuations, all of which can accelerate their degradation over time. By encasing the LEDs in a solid, waterproof layer, potting compounds effectively shield them from these harmful elements, thus minimizing the risk of premature failure.

Moisture ingress is one of the primary culprits behind LED deterioration. The internal components of LEDs are susceptible to corrosion when exposed to moisture, which can result in a decline in performance and eventual malfunction. LED potting compounds counteract this threat by creating an impenetrable barrier that prevents water molecules from penetrating the encapsulated area. This moisture resistance is essential, particularly in outdoor and industrial applications where LEDs are exposed to harsh environmental conditions.

Furthermore, LED potting compounds offer excellent thermal management properties that are crucial in prolonging LED lifespan. During operation, LEDs produce heat, and too much heat might eventually deteriorate their dependability and performance. Potting compounds with high thermal conductivity help dissipate heat away from the LED junction, maintaining optimal operating temperatures and preventing thermal stress-induced failures.

In addition to moisture and thermal protection, LED potting compounds provide mechanical reinforcement to the delicate LED components. They act as a shock-absorbing layer, dampening vibrations and preventing physical damage caused by mechanical shocks or impacts. This mechanical stability ensures the LEDs remain intact and operational even in demanding environments.

Moreover, LED potting compounds come in various formulations to cater to specific application requirements. Whether for indoor lighting fixtures, automotive headlights, or underwater illumination, manufacturers can choose the appropriate potting compound that offers the desired level of protection and performance.

How does LED potting compound compare to conformal coatings in terms of protection?

In electronic device manufacturing, robust protection against environmental factors is paramount. Two commonly utilized methods for safeguarding sensitive components are LED potting compounds and conformal coatings. Both have unique benefits, but knowing how they differ is essential to choosing the best option for a given set of circumstances.

LED Potting Compound:

- Encapsulation Strength: LED potting compound offers exceptional encapsulation strength, forming a solid barrier around components and shielding them from moisture, dust, and other contaminants.

- Thermal Conductivity: Many LED potting compounds boast excellent thermal conductivity properties, dissipating heat efficiently and preventing overheating issues.

- Shock and Vibration Resistance: With high impact resistance, LED potting compounds provide robust protection against mechanical stresses, including shock and vibration, enhancing the durability of electronic assemblies.

- Customization Options: LED potting compounds come in various formulations, allowing manufacturers to tailor the material’s properties to meet specific requirements, such as flexibility, hardness, and curing time.

Conformal Coatings:

- Thin Film Application: Conformal coatings offer a thin film application, providing a protective layer that conforms precisely to the contours of electronic components and PCBs, ensuring coverage even in intricate designs.

- Chemical Resistance: Certain conformal coatings exhibit superior chemical resistance, guarding against corrosion caused by exposure to harsh chemicals or environmental pollutants.

- Repairability: Conformal coatings can be removed and re-applied relatively quickly, facilitating repairs and component replacements without compromising the assembly’s integrity.

- UV Stability: Some conformal coatings offer enhanced UV stability, preventing degradation and yellowing of components exposed to prolonged sunlight or UV radiation.

Comparison:

- Protection Level: LED potting compounds typically provide a higher level of protection due to their robust encapsulation and superior resistance to environmental factors.

- Application Flexibility:Conformal coatings offer greater flexibility in application, particularly for assemblies with intricate designs or components requiring frequent maintenance.

- Thermal Management: Because of their exceptional thermal conductivity, LED potting compounds are perfect for applications where effective heat dissipation is essential.

Can LED potting compound be removed or reworked if necessary?

LED potting compounds are commonly used to protect LEDs from environmental hazards and provide mechanical support. However, there are instances where removal or rework of the potting compound may be necessary, such as for repairs, upgrades, or component replacement. Let’s explore whether LED potting compounds can be removed or reworked and the considerations involved:

- Type of Potting Compound:The removability or reworkability of LED potting compounds largely depends on their formulation. Some potting compounds are designed to be permanent and offer high chemical and mechanical resistance, making them difficult to remove or rework. On the other hand, specific formulations are engineered to be removable or reworkable, allowing for easier access to components when needed.

- Removal Methods:If the potting compound needs to be removed, several methods can be employed depending on the type of compound and the application requirements. Standard removal methods include mechanical methods such as scraping or drilling, thermal methods involving heat application to soften the compound, or chemical methods using solvents or strippers specifically formulated to dissolve the potting material without damaging surrounding components.

- Reworking Considerations:Reworking LED potting compounds requires careful consideration to avoid damaging the LED or other electronic components. It may involve partial removal of the potting material, which should be performed precisely and cautiously to prevent unintended damage. Additionally, proper cleaning and preparation of the area before reapplication of the potting compound are essential to ensure optimal adhesion and performance.

- Impact on Performance:Even though some LED potting compounds can be removed or reworked, it’s important to consider how that might affect the LED device’s dependability and performance. Repeated removal and rework processes can introduce stress to the components and affect their functionality. Therefore, minimizing the need for rework and carefully planning maintenance procedures to mitigate any adverse effects is advisable.

How does LED potting compound contribute to cost-effectiveness in electronic manufacturing processes?

In the fast-paced world of electronic manufacturing, efficiency and cost-effectiveness are paramount. LED potting compound, a versatile material, plays a significant role in streamlining manufacturing processes and reducing costs. Let’s delve into how this compound contributes to cost-effectiveness:

Improved Product Durability:

- LED potting compound enhances the durability of electronic components by protecting against moisture, dust, and other environmental factors.

- Its increased durability reduces the need for frequent replacements or repairs, saving on maintenance costs in the long run.

Enhanced Thermal Management:

- The compound’s thermal conductivity properties help dissipate heat generated by LEDs, preventing overheating and prolonging the lifespan of electronic devices.

- Improved thermal management reduces the risk of component failure, minimizing warranty claims and associated expenses.

Optimized Production Efficiency:

- LED potting compound facilitates faster production cycles by simplifying the assembly process.

- Its self-leveling properties ensure uniform encapsulation, reducing the need for manual adjustments and minimizing production errors.

- Streamlined production processes result in higher throughput and lower labor costs per unit produced.

Reduced Material Waste:

- The precise application of LED potting compound minimizes material waste during manufacturing.

- Its adaptability to intricate forms and dimensions guarantees effective use and lowers the expense of disposing of extra material.

Cost-Efficient Inventory Management:

- Utilizing LED potting compounds with a longer shelf life reduces the risk of material wastage due to expiration.

- Manufacturers can optimize inventory levels, minimizing storage costs and the need for frequent replenishment orders.

Compliance with Industry Standards:

- LED potting compounds are formulated to meet stringent industry regulations, ensuring safety and environmental standards compliance.

- Avoiding non-compliance issues helps prevent costly fines and penalties, safeguarding the company’s reputation and bottom line.

Conclusion

In conclusion, LED potting compound stands as a cornerstone in the realm of electronic engineering, offering a myriad of benefits ranging from protection against environmental hazards to enhancing the longevity and performance of LED devices. As technology advances and the demand for efficient and durable electronic components grows, the role of LED potting compound becomes increasingly indispensable. By understanding its applications, properties, and benefits, engineers can make informed decisions to optimize the reliability and functionality of LED-based systems.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

The Comprehensive Guide to Epoxy Potting Compound Manufacturers

The Comprehensive Guide to Epoxy Potting Compound Manufacturers Epoxy potting compounds are essential materials in the electronics industry, providing robust protection for sensitive components against

The Essential Guide to Potting Materials for Electronics

The Essential Guide to Potting Materials for Electronics In the rapidly evolving field of electronics, ensuring device reliability and longevity is critical. One of the

The Expanding Horizon of the Mini Silicone Optical Glue Market

The Expanding Horizon of the Mini Silicone Optical Glue Market The mini silicone optical glue market is witnessing unprecedented growth, fueled by technological advancements and

The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics

The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling functionality in

Comprehensive Insights on PCB Encapsulation in Potting Material

Comprehensive Insights on PCB Encapsulation in Potting Material In the fast-evolving landscape of electronics, ensuring the durability, reliability, and longevity of printed circuit boards

The Vital Role of Industrial Silicone Adhesive Manufacturers in Modern Industry

The Vital Role of Industrial Silicone Adhesive Manufacturers in Modern Industry In today’s fast-paced industrial landscape, the demand for reliable and durable adhesives is