Potting Compound For Solar Energy

Solar power stands out as a promising solution to our energy needs in the ever-evolving landscape of renewable energy. Solar panels are at the forefront of this technology, capturing sunlight and converting it into electricity. However, the efficiency and longevity of solar panels depend not only on the quality of the photovoltaic cells but also on the materials used to protect and insulate them. One such crucial material is a potting compound, vital in safeguarding solar panels against environmental factors and ensuring their optimal performance. This article delves into the significance of potting compounds for solar energy applications.

Understanding Potting Compound

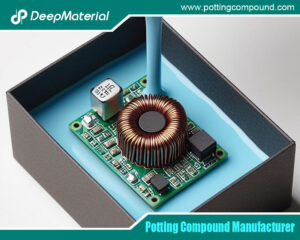

A potting compound, or potting resin or encapsulant, is used to encapsulate electronic components, protecting against moisture, dust, vibrations, and other external factors. In solar energy, potting compound is applied to solar panels to preserve delicate elements such as photovoltaic cells, junction boxes, and wiring from environmental damage.

Enhancing Durability

Solar panels are typically exposed to harsh environmental conditions, including temperature fluctuations, moisture, UV radiation, and mechanical stress. Without adequate protection, these factors can degrade the performance and lifespan of solar panels over time. The potting compound acts as a barrier, shielding the sensitive electronics from such elements and extending the durability of the solar panel system.

Preventing Moisture Ingress

Moisture ingress is one of the primary concerns for solar panels, as even small amounts of water infiltration can lead to corrosion, electrical shorts, and reduced efficiency. Potting compound forms a waterproof seal around the components, preventing moisture from seeping into critical areas and causing damage. This protection is particularly crucial for solar panels installed in humid or coastal environments where exposure to moisture is heightened.

Ensuring Electrical Insulation

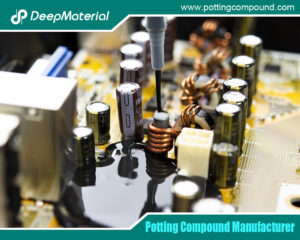

In addition to protecting against moisture, the potting compound provides electrical insulation, preventing conductive materials from coming into contact with each other and causing short circuits. This insulation is essential for maintaining the integrity of the electrical connections within the solar panel, ensuring reliable performance and safety.

Improving Thermal Management

Solar panels generate heat during operation, and excessive heat can degrade the performance of photovoltaic cells. Potting compounds with thermal conductivity properties helps dissipate heat more effectively, reducing the risk of hotspots and ensuring consistent performance across the panel. Proper thermal management also contributes to the longevity of solar panels by minimizing thermal stress on internal components.

Enhancing Environmental Resistance

Solar panels are exposed to various environmental contaminants, including dust, dirt, salt, and chemicals. Potting compound with high chemical resistance and anti-corrosion properties provides an additional layer of defense against these pollutants, preserving the functionality of the solar panel system even in harsh environments.

Facilitating Manufacturing and Installation

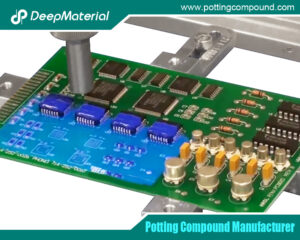

From a manufacturing perspective, potting compound streamlines the production process by simplifying the assembly of solar panels and ensuring uniform components encapsulation. Its pourable or injectable nature allows for precise application and customization according to panel design requirements. During installation, the potting compound assures the panels remain protected and perform optimally throughout their operational life.

Conclusion

The importance of potting compounds cannot be overstated in the realm of solar energy. By offering robust protection against environmental hazards, ensuring electrical insulation, improving thermal management, and simplifying manufacturing and installation processes, potting compound plays a crucial role in enhancing solar panels’ durability, reliability, and efficiency. As the demand for clean and sustainable energy continues to rise, investing in high-quality potting compounds is essential for maximizing the performance and longevity of solar energy systems.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

Potting Compound vs. Epoxy: A Comprehensive Comparison

Potting Compound vs. Epoxy: A Comprehensive Comparison In the world of electronics, manufacturing, and material encapsulation, two terms frequently come up: potting compounds and epoxy.

Potting Compound for PCB

Potting Compound for PCB A potting compound is a liquid or semi-liquid material that is poured or injected over a PCB or electronic assembly, then

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds Electronic potting compounds play a vital role in the electronics industry. They can

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices In modern industrial manufacturing, encapsulating materials are widely used in numerous

A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies In the field of electronic manufacturing, the encapsulation process of printed

Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation During the operation of electronic devices, the PCB (Printed Circuit