Potting Compound For Micro-Electronics

Microelectronics represent the pinnacle of miniaturization in electronics, enabling the development of increasingly compact and powerful devices. From smartphones to medical implants, microelectronics have revolutionized numerous industries, offering unprecedented levels of functionality in diminutive packages. However, as devices shrink in size, they become more susceptible to environmental factors and mechanical stress, necessitating innovative solutions for protection and reliability. In this article, we delve into the significance of potting compounds for microelectronics and how they bolster the performance and resilience of these cutting-edge devices.

Understanding Micro-Electronics:

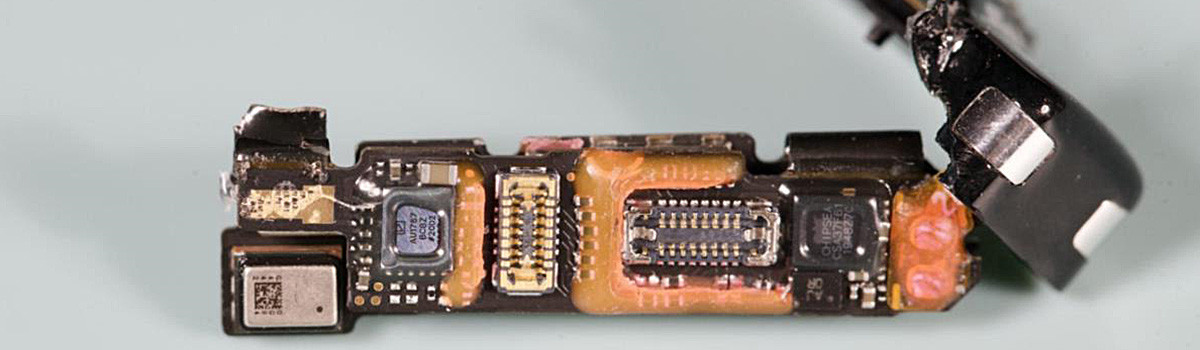

Micro-electronics encompass a broad spectrum of devices characterized by their minute size and intricate circuitry. These devices often incorporate microprocessors, sensors, and other miniature components, enabling sophisticated functionalities in constrained spaces. Micro-electronics proliferation has fueled advancements in fields such as telecommunications, healthcare, automotive, and consumer electronics, driving innovation and reshaping the technological landscape.

Challenges Faced by Micro-Electronics:

Despite their remarkable capabilities, micro-electronics face many challenges threatening their reliability and longevity. Miniaturization renders these devices more susceptible to moisture ingress, thermal fluctuations, mechanical stress, and vibration-induced damage. Furthermore, the delicate nature of micro-electronic components heightens the risk of performance degradation or failure when exposed to harsh environments or operational stresses.

The Role of Potting Compounds:

Potting compounds emerge as a versatile solution for safeguarding micro-electronic devices against external threats and ensuring robust performance in diverse operating conditions. These compounds, typically composed of epoxy resins, silicones, or polyurethanes, offer a range of benefits tailored to the unique requirements of micro-electronics:

Encapsulation and Environmental Protection:

Potting compounds encapsulate delicate electronic components, forming a protective barrier that shields them from moisture, dust, chemicals, and other environmental contaminants. This airtight seal prevents corrosion, oxidation, and electrochemical degradation, extending the lifespan of micro-electronic devices and maintaining their functionality in harsh operating environments.

Thermal Management:

Effective thermal management is critical for micro-electronics to dissipate heat generated during operation and maintain optimal operating temperatures. Potting compounds with high thermal conductivity facilitate heat transfer away from sensitive components, preventing overheating and thermal-induced failures. By enhancing thermal dissipation, these compounds contribute to the reliability and efficiency of micro-electronic systems.

Mechanical Stability:

Micro-electronics are susceptible to mechanical stress, including shock and vibration, which can compromise their structural integrity and solder connections. Potting compounds act as cushions, providing mechanical support and dampening vibrations to minimize the risk of physical damage. This ensures the integrity of solder joints, wire bonds, and delicate components, enhancing microelectronic devices’ durability and shock resistance.

Dielectric Properties and Electrical Insulation:

Potting compounds exhibit excellent dielectric properties, serving as insulating materials that prevent electrical short circuits and signal interference within micro-electronic circuits. This insulation is crucial for maintaining signal integrity, preventing electrical leakage, and ensuring the reliable operation of sensitive electronic components in micro-electronic devices.

Conclusion:

In conclusion, potting compounds are pivotal in fortifying the resilience and performance of micro-electronic devices against environmental, thermal, mechanical, and electrical challenges. Potting compounds enable the seamless integration of microelectronics into a wide range of applications by encapsulating components, providing environmental protection, enhancing thermal management, ensuring mechanical stability, and offering electrical insulation. As the demand for miniaturized, high-performance devices continues to grow, the utilization of advanced potting compounds will remain indispensable for unlocking the full potential of microelectronics across diverse industries.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

The Potting and Encapsulating Compounds Market: An In-Depth Exploration of Trends, Innovations, and Future Prospects

The Potting and Encapsulating Compounds Market: An In-Depth Exploration of Trends, Innovations, and Future Prospects In the rapidly evolving technology landscape, the potting and

The Comprehensive Guide to Polyurethane Potting Compound Manufacturers

The Comprehensive Guide to Polyurethane Potting Compound Manufacturers In today’s rapidly advancing technological landscape, the protection and reliability of electronic components have become paramount.

The Comprehensive Guide to Epoxy Potting Compound Manufacturers

The Comprehensive Guide to Epoxy Potting Compound Manufacturers Epoxy potting compounds are essential materials in the electronics industry, providing robust protection for sensitive components against

The Essential Guide to Potting Materials for Electronics

The Essential Guide to Potting Materials for Electronics In the rapidly evolving field of electronics, ensuring device reliability and longevity is critical. One of the

The Expanding Horizon of the Mini Silicone Optical Glue Market

The Expanding Horizon of the Mini Silicone Optical Glue Market The mini silicone optical glue market is witnessing unprecedented growth, fueled by technological advancements and

The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics

The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling functionality in