High-Temperature Potting Compound

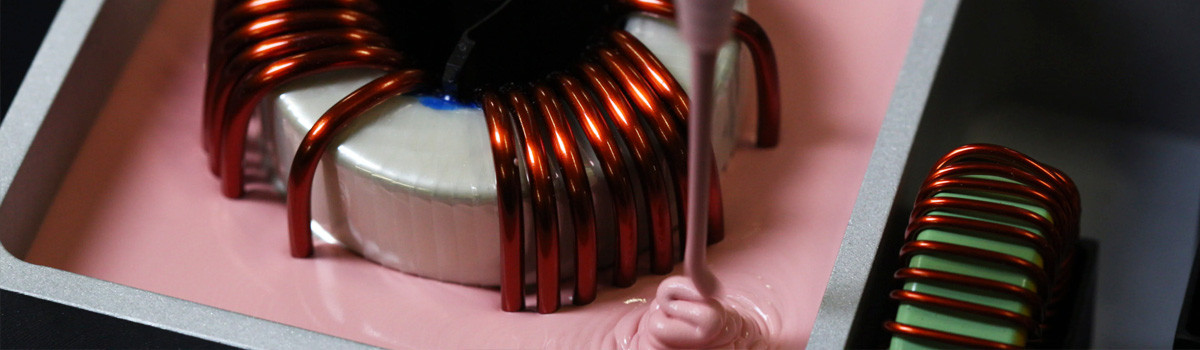

High-temperature potting compounds are crucial materials used in various industrial applications requiring extreme heat resistance. These compounds are designed to encapsulate electronic components, providing insulation and protection against heat, moisture, chemicals, and mechanical stress. From electrical transformers to automotive electronics, aerospace systems, and industrial machinery, high-temperature potting compounds play a vital role in ensuring the reliability and longevity of critical equipment operating under harsh conditions. This category delves into the essential aspects, applications, and considerations surrounding high-temperature potting compounds.

Table of Contents

ToggleVital Points That Demand Your Attention:

What are high-temperature potting compounds?

High-temperature potting compounds are specialized materials used in electronics, aerospace, automotive, and other industries where components are subjected to extreme temperatures. These compounds encapsulate or protect electronic components, wires, and circuits from environmental factors such as heat, moisture, chemicals, and mechanical stress.

One of the primary functions of high-temperature potting compounds is to provide thermal insulation and conductivity control. They act as a barrier between the component and the external environment, preventing heat transfer that could damage sensitive electronic parts. This insulation also helps maintain stable operating temperatures within the device, ensuring optimal performance and longevity.

These compounds are typically formulated using thermally conductive materials such as ceramics, silicones, epoxies, and polyurethanes. Depending on the specific formulation, these materials offer excellent heat resistance and can withstand temperatures ranging from several hundred to over a thousand degrees Celsius.

In addition to thermal properties, high-temperature potting compounds also offer excellent electrical insulation. This is crucial for protecting electronic components from short circuits and other electrical failures, especially in high-temperature environments where traditional insulating materials may degrade or fail.

Another essential characteristic of these compounds is their ability to adhere to various substrates, including metals, plastics, and ceramics. This ensures secure component encapsulation and prevents the ingress of moisture or contaminants that could compromise performance or reliability.

High-temperature potting compounds come in various forms, including liquids, pastes, and putties, allowing for flexibility in application methods. They can be poured, injected, or dispensed manually or using automated equipment, depending on the application’s specific requirements.

High-temperature potting compounds are critical in protecting electronic components and ensuring the reliability of devices operating in extreme thermal environments. Their thermal insulation, electrical properties, adhesion characteristics, and versatility make them indispensable in various industrial applications.

How do high-temperature potting compounds differ from standard potting compounds?

High-temperature potting compounds, epoxy resins, or thermally conductive potting compounds are designed to withstand extreme heat conditions without losing their structural integrity or performance. These compounds differ significantly from standard potting compounds in several key aspects:

- Temperature Resistance: The primary distinction lies in their ability to withstand high temperatures. High-temperature potting compounds are formulated to resist temperatures ranging from 150°C to over 300°C, whereas standard potting compounds typically have lower thermal resistance, usually up to around 100°C. This makes high-temperature potting compounds ideal for applications subjected to extreme heat, such as in automotive, aerospace, and industrial environments.

- Thermal Conductivity: High-temperature potting compounds often exhibit higher thermal conductivity than standard ones. This property allows for efficient dissipation of heat generated within electronic components, preventing overheating and ensuring optimal performance. Enhanced thermal conductivity is crucial in applications where heat management is critical to maintaining the reliability and longevity of electronic devices.

- Chemical Stability: High-temperature potting compounds are engineered to maintain their stability and integrity when exposed to harsh chemicals and environmental factors, such as oils, fuels, solvents, and moisture. They offer superior resistance to degradation, corrosion, and chemical attack compared to standard potting compounds, ensuring long-term reliability in challenging operating conditions.

- Mechanical Strength: Another vital difference is in their mechanical strength and durability. High-temperature potting compounds are formulated to provide robust adhesion and structural support, even at elevated temperatures. They exhibit excellent resistance to thermal cycling, shock, and vibration, minimizing the risk of damage or failure in demanding applications.

- Specialized Formulations: Manufacturers offer a variety of specialized formulations of high-temperature potting compounds tailored to specific requirements, such as flexibility, low shrinkage, flame retardancy, or electrical insulation. These formulations cater to diverse applications across various industries, providing engineers with flexibility and customization options to meet their unique needs.

High-temperature potting compounds distinguish themselves from standard potting compounds through their superior temperature resistance, thermal conductivity, chemical stability, mechanical strength, and specialized formulations. These advanced properties make them indispensable for protecting electronics and electrical components operating in extreme heat environments, ensuring optimal performance, reliability, and longevity.

What are the primary components of high-temperature potting compounds?

High-temperature potting compounds are essential materials used in various industries where there’s a need for robust protection against extreme temperatures, chemicals, moisture, and other environmental factors. These compounds typically contain several primary components carefully formulated to provide thermal stability and insulation. Here are the key components:

- Resins: Resins form the matrix of the potting compound, providing structural integrity and binding other components together. Epoxy resins are commonly used due to their excellent thermal and chemical resistance. They provide the compound with strength and stability, even at high temperatures.

- Fillers: Fillers are added to improve the mechanical properties of the compound and reduce cost. Joint fillers include silica, alumina, and various ceramic powders. These materials enhance thermal conductivity, improve dimensional stability, and reinforce the resin matrix.

- Curing Agents: Curing agents initiate the cross-linking reaction of the resin, transforming it from a liquid to a solid state. They determine the curing characteristics and final properties of the compound. For high-temperature applications, curing agents with high thermal stability are chosen to ensure the integrity of the compound at elevated temperatures.

- Modifiers: Modifiers are additives incorporated into the formulation to enhance specific properties of the compound. For high-temperature potting compounds, modifiers may include flame retardants to improve fire resistance, antioxidants to prevent degradation at high temperatures, and adhesion promoters to ensure strong bonding with substrates.

- Solvents: Solvents adjust the compound’s viscosity for ease of application. However, solvents are minimized or eliminated in many high-temperature formulations to prevent outgassing and ensure dimensional stability during curing.

- Inorganic Materials: Inorganic materials such as ceramics, glass fibers, or metals may be added to improve thermal conductivity and mechanical strength. These materials can withstand extreme temperatures and provide additional reinforcement to the compound.

- Cross-linking Agents: In some formulations, cross-linking agents are added to promote stronger chemical bonds between polymer chains, enhancing the compound’s overall durability and thermal stability.

High-temperature potting compounds typically combine resins, fillers, curing agents, modifiers, inorganic materials, solvents (if necessary), and cross-linking agents. Each component is crucial in providing the desired properties required for applications in high-temperature environments.

What is the temperature range typically covered by high-temperature potting compounds?

High-temperature potting compounds are specially formulated materials designed to withstand elevated temperatures without degrading or losing their structural integrity. These compounds find applications in various industries, such as electronics, automotive, aerospace, and energy, where exposure to high temperatures is expected. The temperature range covered by high-temperature potting compounds can vary depending on the specific formulation and intended application, but typically, they can withstand temperatures ranging from around 150°C to over 300°C.

High-temperature potting compounds may begin to soften or degrade slightly at the lower end of the temperature range, but they still maintain their structural integrity and insulation properties. This lower limit is often around 150°C, making these compounds suitable for applications requiring moderate heat resistance, such as automotive under-the-hood electronics or industrial control systems.

High-temperature potting compounds perform reliably as the temperature increases, offering excellent thermal stability and insulation. Many formulations can withstand temperatures between 200°C and 250°C without significant degradation. This level of heat resistance makes them suitable for use in environments where exposure to heat generated by machinery, engines, or industrial processes is expected.

Some advanced high-temperature potting compounds are engineered to withstand even higher temperatures, surpassing 300°C. These compounds are typically used in demanding applications such as aerospace, where components may be exposed to extreme temperatures during flight or near engines and propulsion systems. They may also find use in energy applications, such as oil and gas drilling equipment or high-temperature electrical systems.

The precise temperature range covered by a specific high-temperature potting compound depends on several factors, including the type of resin used, filler materials, curing process, and any additives included to enhance thermal stability. Manufacturers may tailor formulations to meet the requirements of specific applications, resulting in a wide range of temperature resistance capabilities within the category of high-temperature potting compounds. Overall, these materials play a crucial role in enabling the reliable operation of electronic and mechanical systems in challenging thermal environments.

What industries commonly use high-temperature potting compounds?

High-temperature potting compounds find applications across various industries where there is a need for protection, insulation, and stability in high-temperature environments. These compounds are specially formulated to withstand elevated temperatures without degrading, ensuring the integrity of electronic components, machinery, and structures. Here are some industries commonly utilizing high-temperature potting compounds:

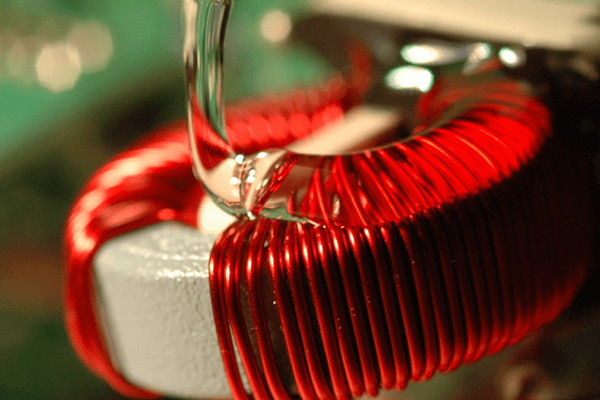

- Electronics and Electrical: Within this sector, high-temperature potting compounds are extensively used for encapsulating and protecting sensitive electronic components such as power supplies, transformers, sensors, and circuit boards. They safeguard these components from thermal shock, vibration, and moisture, thus extending their lifespan and reliability.

- Automotive: In the automotive industry, high-temperature potting compounds are employed for various applications, including encapsulating ignition coils, sensors, and control modules. These compounds provide thermal stability and protection against harsh operating conditions in engine compartments, exhaust systems, and braking systems.

- Aerospace and Defense: High-temperature potting compounds are crucial in aerospace and defense applications where extreme temperatures, vibration, and shock are prevalent. They are used for potting avionics, radar equipment, missile guidance systems, and other critical electronic components, ensuring their performance and reliability in demanding environments.

- Oil and Gas: In the oil and gas industry, where equipment operates in high-temperature and high-pressure environments, potting compounds protect electronic instrumentation, sensors, and control systems used in drilling, production, and refining processes. These compounds help maintain the functionality of equipment exposed to extreme conditions.

- Renewable Energy: High-temperature potting compounds are vital in renewable energy sectors such as solar and wind power. They encapsulate and protect electronics and electrical components in solar panels, wind turbines, inverters, and energy storage systems, ensuring their durability and performance in outdoor environments with fluctuating temperatures.

- Industrial Manufacturing: Various manufacturing processes involve high temperatures, and potting compounds protect electronic controls, sensors, and monitoring systems in industrial machinery such as furnaces, ovens, and presses. This ensures reliable operation and minimizes downtime due to component failure.

High-temperature potting compounds play a crucial role in ensuring electronic and electrical components’ reliability, performance, and longevity across a wide range of industries operating in extreme temperature environments. Their ability to withstand elevated temperatures and provide protection against thermal stress makes them indispensable in modern technological applications.

What are the benefits of using high-temperature potting compounds?

High-temperature potting compounds offer a range of benefits across various industries, owing to their ability to withstand extreme temperatures and harsh environmental conditions. Here are some key advantages:

- Thermal Stability: High-temperature potting compounds excel in environments with elevated temperatures. They maintain their structural integrity and functionality, ensuring reliable performance even in extreme heat conditions, making them ideal for aerospace, automotive, and electronics applications.

- Electrical Insulation: These compounds provide excellent electrical insulation properties, preventing short circuits and electrical failures even when exposed to high temperatures. This characteristic is crucial in electronic devices, power systems, and automotive components where electrical insulation is critical for safety and performance.

- Chemical Resistance: High-temperature potting compounds often resist various chemicals, including oils, solvents, and fuels. This resistance ensures longevity and reliability in environments where exposure to corrosive substances is daily, such as industrial machinery, oil drilling equipment, and chemical processing plants.

- Mechanical Strength: These compounds offer high mechanical strength and stability, protecting delicate electronic components and assemblies from mechanical stress, vibrations, and shocks. Their ability to maintain structural integrity under mechanical strain enhances the durability and reliability of encapsulated devices and systems.

- Environmental Protection: High-temperature potting compounds form a protective barrier around sensitive components, shielding them from moisture, dust, and other environmental contaminants. This protection is essential for outdoor applications, harsh industrial environments, and automotive under-the-hood applications where exposure to environmental hazards is a concern.

- Dimensional Stability: These compounds typically exhibit low shrinkage during curing, ensuring dimensional stability and precise component encapsulation. This characteristic is crucial for maintaining tight tolerances and preventing voids or gaps that could compromise the performance or reliability of encapsulated devices.

- Ease of Application: Many high-temperature potting compounds are formulated for easy application, offering convenient mixing, pouring, and curing processes. This simplifies manufacturing and assembly processes, reducing production time and costs for encapsulated products.

The benefits of using high-temperature potting compounds include thermal stability, electrical insulation, chemical resistance, mechanical strength, environmental protection, dimensional stability, and ease of application, making them indispensable for a wide range of demanding applications across various industries.

How do high-temperature potting compounds provide thermal insulation?

High-temperature potting compounds are specialized materials that provide thermal insulation in demanding environments. They achieve this through several vital mechanisms inherent in their composition and structure.

These compounds often consist of thermally resistant polymers or resins, such as silicone or epoxy, with inherently low thermal conductivity. Thermal conductivity refers to a material’s ability to conduct heat. Using polymers with low thermal conductivity minimizes heat transfer through the potting compound, thus providing adequate thermal insulation. Additionally, these polymers can withstand high temperatures without significant degradation, ensuring the integrity of the insulation under extreme thermal conditions.

Secondly, high-temperature potting compounds may incorporate fillers or additives with insulating properties. Typical filler materials include ceramics, glass microspheres, or mineral-based powders. These fillers create a barrier within the compound, reducing the movement of heat energy through the material. They effectively scatter and reflect heat, preventing it from passing through the insulation effortlessly. Furthermore, these fillers can enhance the mechanical strength and stability of the compound, improving its performance in harsh environments.

Moreover, the formulation of high-temperature potting compounds often involves careful porosity control. Manufacturers can minimize convective heat transfer by controlling the distribution and size of pores within the material. Convection occurs when heat is transferred through the movement of fluids, such as air or gases, within pores or voids. High-temperature potting compounds can limit convective heat transfer by reducing porosity and enhancing thermal insulation properties.

Additionally, the application method of these compounds plays a crucial role in maximizing thermal insulation. Proper encapsulation of heat-generating components ensures efficient heat dissipation pathways, preventing localized hotspots and maintaining overall thermal stability.

High-temperature potting compounds provide thermal insulation through low-thermal conductivity polymers, insulating fillers, controlled porosity, and practical application techniques. These compounds can protect electronic components, machinery, and other sensitive materials from extreme heat environments by leveraging these mechanisms, ensuring reliable performance and longevity.

Can high-temperature potting compounds withstand thermal cycling?

High-temperature potting compounds are formulated to endure extreme thermal conditions, typically ranging from -50°C to 200°C or higher. These compounds are engineered to provide robust protection for electronic components, ensuring insulation, stability, and longevity even in demanding environments.

Thermal cycling involves repeated heating and cooling cycles and can exert significant stress on materials. High-temperature potting compounds are designed to withstand such thermal cycling by exhibiting several key characteristics:

- Thermal Stability: These compounds possess excellent thermal stability, maintaining their structural integrity and electrical insulation properties across a wide temperature range.

- Low Coefficient of Thermal Expansion (CTE): A low CTE minimizes dimensional changes during temperature variations, reducing the risk of cracks or delamination that can compromise encapsulation.

- Flexibility: Some potting compounds are formulated to remain flexible even at high temperatures, allowing them to accommodate thermal expansion and contraction without cracking.

- Adhesion: Strong adhesion to various substrates ensures that the potting compound remains securely bonded to the components, preventing the ingress of moisture or contaminants that could degrade performance.

- Chemical Resistance: Resistance to chemicals and solvents further enhances the durability of high-temperature potting compounds, protecting electronic assemblies from environmental hazards.

- Accelerated Testing: Manufacturers subject these compounds to rigorous accelerated aging tests, simulating thousands of thermal cycles to evaluate their long-term performance under real-world conditions.

While high-temperature potting compounds are engineered to withstand thermal cycling, proper application techniques and adequate cure times are crucial for optimal performance. Additionally, selecting the appropriate compound based on specific application requirements, such as temperature range, thermal cycling frequency, and environmental exposure, is essential for maximizing reliability and longevity.

What role do high-temperature potting compounds play in electronics manufacturing?

High-temperature potting compounds are essential in electronics manufacturing, particularly for applications where components are subjected to elevated operating temperatures. These compounds serve multiple crucial roles in ensuring electronic devices’ reliability, performance, and longevity.

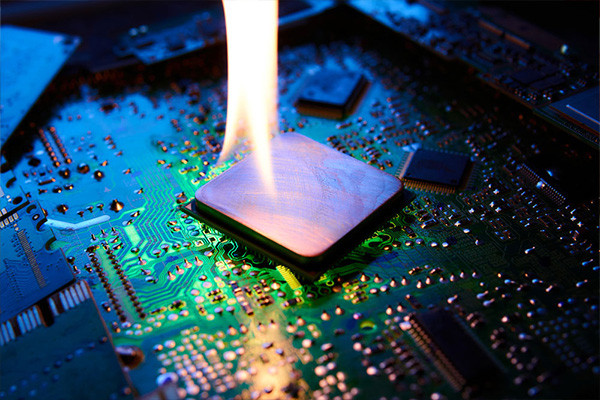

First and foremost, high-temperature potting compounds provide thermal insulation and heat dissipation properties. Electronics often generate heat during operation, and excessive heat can degrade performance or even lead to component failure. Potting compounds encapsulate sensitive components, forming a protective barrier that helps to dissipate heat away from critical parts, thereby preventing overheating and maintaining optimal operating temperatures.

Moreover, these compounds protect against environmental factors such as moisture, dust, chemicals, and vibration. By encapsulating electronic assemblies, potting compounds shield delicate components from corrosive agents and physical damage, enhancing the device’s durability and reliability, especially in harsh operating environments.

Another crucial role of high-temperature potting compounds is mechanical stabilization. They provide structural support by securing components within the device, preventing movement or displacement due to mechanical shocks or vibrations. This stabilization minimizes the risk of damage to solder joints, wires, or delicate components, ensuring the integrity of the electronic assembly.

Furthermore, potting compounds contribute to electrical insulation, safeguarding against short circuits and electrical interference. By encapsulating conductive elements, these compounds prevent unintended contact between components, reducing the risk of electrical malfunctions or failures.

In addition to their protective functions, high-temperature potting compounds also aid in the miniaturization of electronic devices. Their ability to encapsulate components without adding significant bulk allows for compact designs, which are essential for limited space applications.

High-temperature potting compounds play a critical role in electronics manufacturing by providing thermal management, environmental protection, mechanical stabilization, electrical insulation, and facilitating compact designs. Their use ensures electronic devices’ reliability, performance, and longevity, particularly in demanding operating conditions.

Are there different types of high-temperature potting compounds available?

Yes, various types of high-temperature potting compounds are designed to provide thermal stability and protection for electronic components operating in extreme environments. These compounds are formulated to withstand elevated temperatures, harsh chemicals, and mechanical stresses while providing electrical insulation and environmental protection. Here are some common types:

- Epoxy Potting Compounds: Epoxy resins are famous for their excellent adhesion, chemical resistance, and thermal stability. Depending on the formulation, they can withstand temperatures ranging from 120°C to 200°C. Epoxy potting compounds are commonly used in power supplies, motors, and automotive electronics applications.

- Silicone Potting Compounds: Silicone-based potting compounds offer exceptional flexibility, thermal stability (up to 250°C), and resistance to moisture, chemicals, and UV radiation. They are ideal for high-temperature resistance and flexibility applications, such as LED lighting, sensors, and aerospace electronics.

- Polyurethane Potting Compounds: Polyurethane resins provide good thermal and mechanical properties and excellent moisture resistance. Depending on the formulation, they can withstand temperatures up to 150°C to 180°C,. Polyurethane potting compounds are commonly used in industrial electronics, automotive sensors, and outdoor lighting applications.

- Phenolic Potting Compounds: Phenolic resins offer high thermal stability and chemical resistance. They can withstand temperatures up to 200°C to 250°C. Phenolic potting compounds are often used in high-temperature environments such as oil and gas drilling equipment, electrical transformers, and aerospace components.

- Ceramic Potting Compounds: Ceramic-filled potting compounds provide exceptional thermal conductivity and insulation properties. They can withstand temperatures exceeding 300°C. Ceramic potting compounds are used in high-power electronic devices, power modules, and automotive engine control units.

- Hybrid Potting Compounds: Some potting compounds combine properties of two or more resin types to achieve specific performance requirements. For example, a hybrid epoxy-silicone compound may offer thermal stability and flexibility, making it suitable for various applications.

High-temperature potting compounds come in various formulations to meet the diverse needs of electronic devices operating in extreme environments. The choice of potting compound depends on factors such as temperature range, chemical resistance, mechanical properties, and application requirements.

How do you select the suitable high-temperature potting compound for a specific application?

Selecting a suitable high-temperature potting compound is crucial for ensuring the durability and performance of electronic components in demanding applications. Here are the key steps to consider when choosing the appropriate compound:

- Identify Application Requirements: Understand the specific requirements of your application, including temperature range, chemical exposure, mechanical stress, and environmental conditions. These factors will dictate the type of potting compound needed.

- Temperature Range: High-temperature potting compounds are designed to withstand elevated temperatures without degradation. Determine the maximum and minimum temperatures the compound will be exposed to during operation.

- Chemical Resistance: Consider the chemicals or solvents the potting compound may contact during its lifetime. Choose a compound that offers resistance to these substances to prevent degradation or failure.

- Mechanical Properties: Evaluate the mechanical stress the potting compound must endure, such as vibration, impact, or thermal cycling. Select a compound with appropriate flexibility, adhesion, and shock-absorption properties to withstand these stresses.

- Electrical Insulation: Ensure the potting compound provides sufficient insulation to protect sensitive electronic components from short circuits or electrical leakage.

- Application Method: Consider the potting process and application method. Some compounds may require specific conditions, such as heat or room temperature. Choose a compound compatible with your manufacturing process.

- Compatibility: Verify compatibility with potted materials, such as circuit boards, wires, or sensors. Incompatible materials could lead to delamination or reduced performance.

- Certifications and Standards: Check if the potting compound meets your application’s relevant industry standards or certifications, such as UL recognition for electrical insulation.

- Cost and Availability: Evaluate the cost-effectiveness and availability of the chosen potting compound. Balance performance requirements with budget constraints and ensure a reliable supply chain.

By considering these factors and conducting thorough testing and evaluation, you can select the suitable high-temperature potting compound that meets the specific needs of your application, ensuring optimal performance and reliability.

Can high-temperature potting compounds resist chemical exposure?

High-temperature potting compounds are specially formulated materials designed to withstand elevated temperatures while providing electrical insulation and environmental protection to electronic components. While these compounds excel in thermal stability, their resistance to chemical exposure can vary depending on their composition and intended application.

Many high-temperature potting compounds use thermosetting resins like epoxy, silicone, or polyurethane. These resins resist various chemicals, including solvents, acids, and bases. However, their performance can be influenced by factors such as the specific chemicals involved, concentration, temperature, and duration of exposure.

Epoxy-based potting compounds are renowned for their chemical resistance, particularly to solvents and acids. They form strong, durable bonds and protect against moisture and environmental contaminants. Additionally, epoxies offer good adhesion to various substrates, enhancing the overall robustness of the encapsulated electronics.

Silicone-based potting compounds offer exceptional thermal stability and flexibility over a wide temperature range. They are inherently resistant to moisture, UV radiation, and many chemicals, making them suitable for harsh operating conditions. Silicone’s molecular structure provides a barrier against moisture and contaminants, ensuring long-term reliability in challenging environments.

Polyurethane potting compounds strike a balance between thermal performance and chemical resistance. They provide reasonable protection against moisture and environmental stresses while offering moderate resistance to chemicals. However, their performance can be compromised by exposure to certain solvents and aggressive chemicals over extended periods.

It’s important to note that while high-temperature potting compounds offer some degree of chemical resistance, they may not be immune to all types of chemical exposure. Engineers and designers must carefully evaluate the specific requirements of their application and select potting materials accordingly. In cases where extreme chemical resistance is needed, additional protective measures such as barrier coatings or specialized encapsulation techniques may be necessary to ensure the longevity and reliability of electronic components in harsh chemical environments.

Are there any environmental considerations when using high-temperature potting compounds?

High-temperature potting compounds play a vital role in various industries, offering protection and stability to electronic components operating in extreme conditions. However, their usage warrants careful consideration of environmental impacts during the manufacturing and disposal stages.

- Chemical Composition: Many high-temperature potting compounds contain chemicals that can harm the environment if not handled properly. Common constituents such as epoxy resins, curing agents, and fillers may include hazardous substances like volatile organic compounds (VOCs) or heavy metals. Manufacturers must adhere to strict regulations to minimize emissions and ensure safe handling practices to mitigate environmental risks.

- Energy Consumption: The production process of high-temperature potting compounds often requires significant energy input, particularly during curing or polymerization stages. Energy-intensive manufacturing processes contribute to carbon emissions and overall environmental footprint. Implementing energy-efficient practices and utilizing renewable energy sources can help mitigate these impacts.

- Waste Generation: Unused or excess potting compounds and waste generated during manufacturing processes pose challenges for disposal. Improper disposal can lead to soil and water contamination, affecting ecosystems and human health. Recycling programs for unused compounds and implementing waste reduction strategies can help minimize environmental pollution.

- End-of-Life Considerations: Properly disposal of potting-compound-encapsulated components is crucial when electronic devices end their lifecycle. Recycling or adequate disposal methods should be employed to prevent leaching of harmful chemicals into the environment. Developing biodegradable or recyclable alternatives to traditional potting compounds can further reduce environmental impacts.

- Long-Term Performance and Durability: High-temperature potting compounds contribute to the longevity and reliability of electronic devices subjected to harsh operating conditions. Enhancing the durability and thermal stability of these compounds can reduce the frequency of component replacement, thereby lowering overall environmental impacts associated with manufacturing and disposal.

While high-temperature potting compounds offer essential benefits for electronic component protection, their usage requires careful consideration of environmental implications throughout the product life cycle. By adopting sustainable manufacturing practices, minimizing waste generation, and exploring eco-friendly alternatives, the ecological footprint of these compounds can be effectively mitigated.

How do high-temperature potting compounds affect the performance of electronic components?

High-temperature potting compounds protect electronic components from harsh environmental conditions, ensuring their longevity and reliability. These compounds, typically made of thermally conductive materials such as epoxy resins or silicone rubber, are designed to withstand elevated temperatures without degrading, thus providing a stable environment for the enclosed components. Their impact on performance can be understood through several key factors:

- Thermal Conductivity: High-temperature potting compounds with good thermal conductivity help dissipate heat generated by electronic components. By efficiently transferring heat away from sensitive parts, these compounds prevent overheating, which can degrade performance and lead to premature failure. Enhanced thermal management contributes to maintaining optimal operating conditions and overall system reliability.

- Mechanical Protection: Potting compounds are a barrier against mechanical stresses such as vibrations, shocks, and impacts. They encapsulate delicate electronic components, shielding them from physical damage and reducing the risk of mechanical failure. Improved mechanical protection ensures the integrity of connections and solder joints, sustaining performance under challenging conditions.

- Environmental Resistance: Electronic components exposed to high temperatures are susceptible to corrosion, moisture ingress, and chemical exposure, compromising performance and lifespan. High-temperature potting compounds provide a protective seal, guarding against environmental contaminants and preventing oxidation or chemical reactions that could degrade component functionality.

- Electrical Insulation: Effective insulation is crucial for maintaining electrical integrity and preventing short circuits or leakage currents, especially in high-temperature environments with a heightened risk of arcing or electrical breakdown. Potting compounds with high dielectric strength offer superior electrical insulation, safeguarding components and circuits from electrical faults.

- Compatibility and Compatibility: Compatibility with a wide range of substrates and components is essential to ensure proper adhesion and integration within electronic assemblies. Moreover, compatibility with manufacturing processes such as potting, curing, and post-processing facilitates efficient production and assembly workflows.

High-temperature potting compounds positively influence the performance of electronic components by providing thermal management, mechanical protection, environmental resistance, electrical insulation, and compatibility. Their ability to withstand elevated temperatures and harsh conditions ensures the reliability and longevity of electronic systems in demanding applications.

Are there any regulatory standards or certifications for high-temperature potting compounds?

ThereThere are regulatory standards and certifications for high-temperature potting compounds, particularly those used in electronic and electrical applications where exposure to elevated temperatures is expected. These standards ensure the potting materials’ safety, reliability, and performance in various environments. Some of the critical standards and certifications include:

- UL Recognition: Underwriters Laboratories (UL) provides recognition for potting compounds through testing and evaluation according to specific standards such as UL 94 for flammability, UL 746B for polymeric materials used in electrical equipment, and UL 746C for polymeric materials used in electrical equipment with specific reference to resistance to high temperatures.

- IEC Standards: The International Electrotechnical Commission (IEC) sets electrical and electronic components standards. For potting compounds, standards such as IEC 60085 (Thermal classification of electrical insulation materials and insulating systems) and IEC 60707 (Guide for the classification of insulating liquids according to fire point and net calorific value) may be applicable.

- IPC Standards: The Institute for Printed Circuits (IPC) develops standards for the electronics industry. Standards such as IPC-CC-830 (Qualification and Performance Specification of Permanent Solder Mask and Flexible Cover Materials) may apply to potting compounds used in electronics manufacturing.

- ISO Certification: ISO 9001 certification ensures that the manufacturer of potting compounds follows quality management standards. ISO 14001 certification ensures adherence to environmental management standards.

- RoHS Compliance: Restriction of Hazardous Substances (RoHS) directive restricts using certain hazardous materials in electrical and electronic equipment. Potting compounds must comply with RoHS regulations to ensure they do not contain harmful substances.

- REACH Compliance: Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation applies to using chemicals in the European Union. Potting compounds must comply with REACH requirements to ensure the safety of human health and the environment.

Compliance with these standards and certifications assures users that high-temperature potting compounds meet specific safety, performance, and environmental criteria, enhancing the reliability and trustworthiness of the electronic and electrical systems in which they are used.

What are the challenges associated with using high-temperature potting compounds?

High-temperature potting compounds offer unique advantages in various industrial applications, providing thermal stability, electrical insulation, and mechanical protection in environments with elevated temperatures. However, they also present several challenges that need to be carefully addressed:

- Thermal Conductivity: While high-temperature potting compounds are designed to withstand elevated temperatures, they may have lower thermal conductivity than metals or other materials. This can lead to heat buildup within the potted components, potentially causing overheating and reduced performance or premature failure of sensitive electronics or machinery.

- Cure Profile: Properly curing high-temperature potting compounds can be challenging, especially in applications where precise control of temperature and time is crucial. Improper curing can result in incomplete polymerization, reduced mechanical strength, increased porosity, and compromised thermal resistance.

- Compatibility: High-temperature potting compounds must be compatible with the materials they come into contact with, including substrates, components, and encapsulated electronics. Chemical incompatibility can lead to degradation of the potting material, corrosion of surrounding materials, or even failure of the entire system.

- Mechanical Properties: While these compounds offer excellent thermal resistance, they may exhibit inferior mechanical properties compared to lower-temperature alternatives. This includes factors such as tensile strength, elongation, and impact resistance, which ensure long-term reliability and durability in harsh operating conditions.

- Cost: High-temperature potting compounds often come at a higher cost than standard potting materials due to their specialized formulations and enhanced thermal properties. Balancing the performance benefits against the increased cost is essential when selecting a potting compound for a particular application.

- Handling and Application: Some high-temperature potting compounds may have specific handling and application requirements, such as mixing ratios, pot life, viscosity, and curing conditions. Proper training and equipment are necessary to ensure consistent and reliable potting results, minimizing the risk of defects or inconsistencies in the finished product.

Addressing these challenges requires a thorough understanding of the application requirements, careful selection of materials, and adherence to best practices in handling, processing, and testing high-temperature potting compounds. Additionally, ongoing research and development efforts aim to improve these materials’ performance, reliability, and cost-effectiveness to meet the evolving needs of various industries.

Can high-temperature potting compounds be customized for specific applications?

High-temperature potting compounds are versatile materials that encapsulate electronic components, protecting environmental factors such as moisture, chemicals, and thermal stress. These compounds can be customized for specific applications, offering tailored properties to meet the unique requirements of various industries.

One key aspect of customization is the selection of base materials. High-temperature potting compounds are often formulated using epoxy, silicone, or polyurethane resins, offering distinct advantages. Epoxy resins, for example, provide excellent adhesion and mechanical strength, while silicone resins offer exceptional flexibility and thermal stability. Polyurethane resins strike a balance between flexibility and rigidity. The appropriate base material depends on operating temperature, chemical exposure, and desired physical properties.

Furthermore, additives and fillers can be incorporated to enhance specific characteristics of the potting compound. For applications requiring superior thermal conductivity, fillers such as aluminum oxide or boron nitride can be added to improve heat dissipation. Conversely, insulating fillers like glass microspheres may be utilized for applications demanding electrical insulation. The concentration and type of fillers can be adjusted to achieve the desired thermal, electrical, or mechanical properties.

Moreover, the curing process of potting compounds can be tailored to suit specific manufacturing requirements. Some formulations cure at room temperature, offering convenience and energy savings during production. Others may require elevated temperatures or UV exposure for rapid curing. Manufacturers can adjust curing time, temperature, and conditions to optimize productivity without compromising the final product’s performance.

Additionally, customization extends to the physical characteristics of the potting compound, such as viscosity, color, and hardness. Viscosity can be adjusted to ensure proper flow and penetration around complex electronic assemblies, while color options facilitate identification and aesthetic preferences. Hardness can be tailored to provide the desired level of protection and vibration resistance.

High-temperature potting compounds can be customized by selecting base materials, incorporating additives, adjusting curing processes, and fine-tuning physical characteristics. This versatility enables manufacturers to address the specific needs of diverse applications, ensuring optimal performance and reliability in challenging environments.

How do you apply high-temperature potting compounds effectively?

Applying high-temperature potting compounds effectively requires careful preparation, proper application techniques, and adherence to safety measures. These compounds commonly encapsulate electronic components or sensitive parts in environments with elevated temperatures. Here’s a guide on how to apply them effectively:

- Preparation: Before starting the potting process, ensure the work area is clean, dry, and well-ventilated. Gather all necessary equipment and materials, including the potting compound, mixing tools, molds, and safety gear such as gloves and goggles.

- Mixing: Follow the manufacturer’s instructions for mixing the potting compound. Typically, this involves combining the resin and hardener in the correct ratios. Use clean mixing tools to ensure uniformity and consistency in the mixture.

- Degassing: Some high-temperature potting compounds may contain air bubbles that can affect the performance of the encapsulated components. Degassing the mixture using a vacuum chamber can help remove these bubbles and improve the overall quality of the potting.

- Application: Carefully pour or inject the mixed potting compound into the prepared mold or directly onto the components to be encapsulated. Ensure thorough coverage while avoiding trapping air pockets. Use a spatula or similar tool to spread the compound evenly if necessary.

- Curing: The potting compound can cure according to the manufacturer’s specifications. This typically involves exposing it to elevated temperatures for a specified period. Ensure that the curing environment is suitable and free from contaminants that could affect the final product.

- Post-curing inspection: Inspect the encapsulated components for any defects or irregularities once cured. Check for proper adhesion, coverage, and absence of air bubbles or voids.

- Safety: Throughout the process, prioritize safety by wearing appropriate protective gear and following safety guidelines provided by the manufacturer. Some potting compounds may emit harmful fumes during curing, so proper ventilation is essential.

- Documentation: Keep records of the potting process, including the type of compound used, mixing ratios, curing conditions, and any other relevant information. This documentation can be valuable for quality control and troubleshooting purposes.

Following these steps, you can effectively apply high-temperature potting compounds to protect electronic components or sensitive parts in demanding environments. Always refer to the specific instructions provided by the manufacturer for the best results.

What are the typical curing methods for high-temperature potting compounds?

High-temperature potting compounds are commonly used in various industries where components need protection from extreme temperatures, chemicals, moisture, and mechanical stress. Curing these compounds is crucial for achieving their desired properties, such as thermal stability, electrical insulation, and mechanical strength. Several curing methods are employed for high-temperature potting compounds:

- Heat Curing: Heat curing is one of the most common methods for curing high-temperature potting compounds. It involves exposing the compound to elevated temperatures for a specific duration. Typically, the compound is placed in an oven or a heated chamber, where it undergoes polymerization or cross-linking to form a solid matrix. The temperature and duration of heat curing depend on the specific compound formulation and manufacturer’s recommendations.

- Room Temperature Curing: Some high-temperature potting compounds are designed to cure at room temperature without requiring additional heat. These compounds often contain special catalysts or accelerators that initiate curing reactions when exposed to air or moisture. Room temperature curing is advantageous for applications where heat curing is impractical or costly.

- Moisture Curing: Moisture-curable potting compounds rely on ambient moisture to initiate curing reactions. These compounds typically contain moisture-sensitive functional groups that react with water vapor in the air to cross-link and form a solid network. Moisture curing is convenient for applications where exposure to moisture is unavoidable.

- UV Curing: UV curing involves exposing the potting compound to ultraviolet (UV) light, which initiates photopolymerization reactions to cure the material. UV-curable potting compounds contain photoinitiators that absorb UV light and generate free radicals or reactive species, leading to cross-linking and curing. UV curing offers rapid curing times and precise control over the curing process.

- Dual-Cure Systems: Dual-cure potting compounds combine two curing mechanisms: heat curing and moisture curing or UV curing and thermal curing. These systems provide versatility and reliability by ensuring curing under various environmental conditions or when one mechanism alone may be insufficient.

Each curing method has advantages and limitations, and the selection depends on factors such as application requirements, substrate compatibility, curing time, and environmental conditions. Manufacturers often provide guidelines and recommendations for selecting the appropriate curing method for specific high-temperature potting compounds.

How do high-temperature potting compounds contribute to the overall reliability of electronic systems?

High-temperature potting compounds play a crucial role in enhancing the reliability and longevity of electronic systems, particularly in harsh environments. These compounds are specially formulated materials designed to encapsulate electronic components, providing insulation, protection, and stability under extreme temperature conditions. Here’s how they contribute to overall system reliability:

- Thermal Management: High-temperature potting compounds have excellent thermal conductivity properties, which enable efficient heat dissipation from electronic components. By facilitating heat transfer away from sensitive parts, they prevent overheating and thermal stress, extending the components’ lifespan and the overall system.

- Environmental Protection: Electronic systems operating in demanding environments, such as automotive, aerospace, and industrial settings, are exposed to contaminants like moisture, chemicals, dust, and vibrations. High-temperature potting compounds form a protective barrier around sensitive components, shielding them from these external factors. This protection reduces the risk of corrosion, electrical short circuits, and other forms of damage, thus improving the system’s reliability.

- Mechanical Stability: The encapsulation provided by potting compounds enhances the mechanical stability of electronic assemblies. It helps to immobilize components and prevent movement or vibration-induced failures. This is particularly critical in applications subject to mechanical shocks or vibrations, where even minor movements can lead to performance degradation or component detachment.

- Electrical Insulation: Potting compounds offer excellent electrical insulation properties, essential for preventing short circuits and electrical breakdowns, especially in high-voltage applications. By insulating conductive elements and avoiding contact with external conductors or the environment, these compounds ensure the integrity and safety of electronic systems.

- Chemical Resistance: High-temperature potting compounds are formulated to resist a wide range of chemicals and solvents, protecting electronic components from corrosive substances in the operating environment. This resistance minimizes the risk of chemical damage and degradation, thereby enhancing the system’s reliability and longevity.

Overall, high-temperature potting compounds significantly improve the reliability of electronic systems by providing thermal management, environmental protection, mechanical stability, electrical insulation, and chemical resistance. Their use helps ensure consistent performance and prolonged service life, even in the most challenging operating conditions.

Conclusion:

In conclusion, high-temperature potting compounds are indispensable materials in industries where extreme heat resistance and reliability are paramount. Their ability to protect electronic components from heat, moisture, chemicals, and mechanical stress ensures the longevity and performance of critical equipment. By understanding their composition, applications, and selection criteria, industries can make informed decisions to optimize the performance and durability of their electronic systems in harsh operating environments.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

The Comprehensive Guide to Polyurethane Potting Compound Manufacturers

The Comprehensive Guide to Polyurethane Potting Compound Manufacturers In today’s rapidly advancing technological landscape, the protection and reliability of electronic components have become paramount.

The Comprehensive Guide to Epoxy Potting Compound Manufacturers

The Comprehensive Guide to Epoxy Potting Compound Manufacturers Epoxy potting compounds are essential materials in the electronics industry, providing robust protection for sensitive components against

The Essential Guide to Potting Materials for Electronics

The Essential Guide to Potting Materials for Electronics In the rapidly evolving field of electronics, ensuring device reliability and longevity is critical. One of the

The Expanding Horizon of the Mini Silicone Optical Glue Market

The Expanding Horizon of the Mini Silicone Optical Glue Market The mini silicone optical glue market is witnessing unprecedented growth, fueled by technological advancements and

The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics

The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling functionality in

Comprehensive Insights on PCB Encapsulation in Potting Material

Comprehensive Insights on PCB Encapsulation in Potting Material In the fast-evolving landscape of electronics, ensuring the durability, reliability, and longevity of printed circuit boards