Potting Material Manufacturer: An In-depth Exploration

- Electronic Potting Material Manufacturer

- August 23, 2024

- adhesive glue manufacturer, Automotive potting material manufacturers, circuit board potting, circuit board potting compound, Connector Potting Compound, deepmaterial potting compound, electrical potting compound, Electronic Encapsulant Potting Compound, Electronic Epoxy Encapsulant Potting Compound, electronic epoxy encapsulant potting compounds, Electronic Epoxy Potting Compound, electronic potting compound, Electronic Potting Compounds Manufacturer, electronic potting material manufacturer, epoxy potting compound, Epoxy potting material manufacturers, Flexible Potting Compound, industrial adhesive suppliers, Industrial Conformal Coating, LED Potting Compound, PCB Potting Compound, polyurethane potting compound, polyurethane potting compound for electronics, potting material for electronic components, potting material for electronics, potting material manufacturer, potting pcb, Silicone Potting Compound, UV Cure Potting Compound, waterproof potting compound

Potting Material Manufacturer: An In-depth Exploration

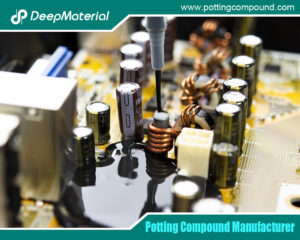

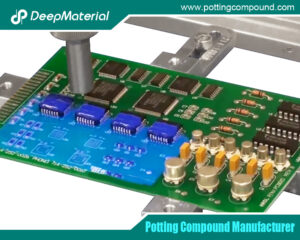

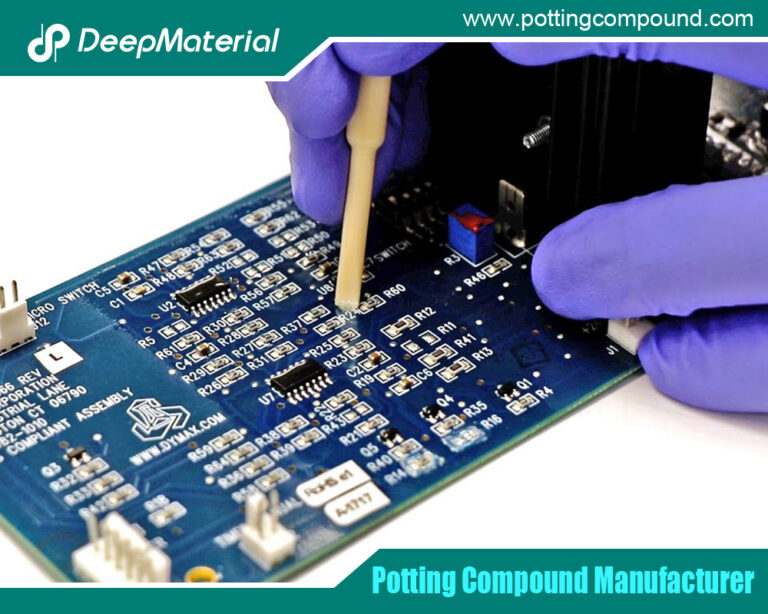

In electronics, the protection and insulation of components are paramount to ensure longevity, reliability, and safety. One of the most crucial processes in achieving this protection is potting, which involves encapsulating electronic components with a protective material known as potting material. The manufacturers of these materials play a critical role in various industries by providing solutions that enhance the performance and durability of electronic devices. This article delves into the intricacies of potting material manufacturing, the types of materials used, the industries that rely on these materials, and the key players in the market.

Understanding Potting Material

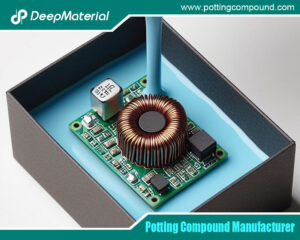

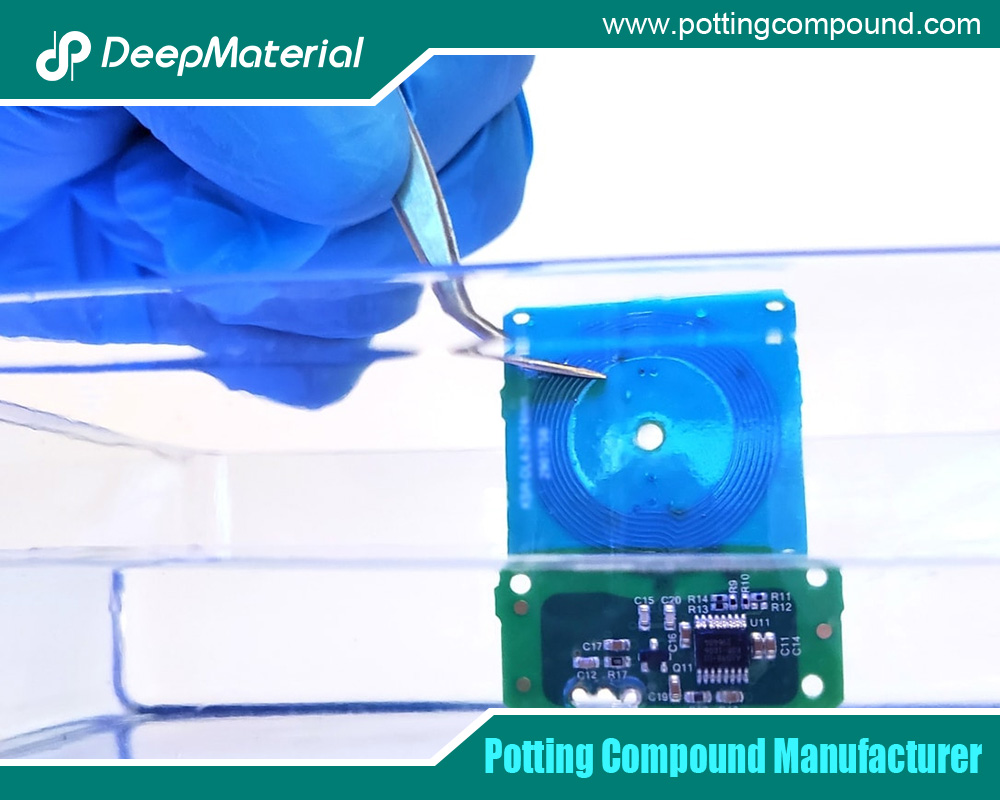

Potting is a process in which electronic components are encapsulated with a liquid compound that hardens to form a solid, protective barrier. This barrier shields the components from environmental factors such as moisture, dust, chemicals, and mechanical stress. Therefore, the potting material must possess specific properties that protect the components while enhancing their performance effectively.

Types of Potting Materials

- Epoxy Resins

- Properties:Epoxy resins are the most commonly used potting materials due to their excellent adhesion, chemical resistance, and mechanical strength. They offer good thermal conductivity and are ideal for applications that require high-temperature resistance.

- Applications:Epoxy resins are widely used in automotive electronics, power supplies, and industrial control systems.

- Polyurethane Resins

- Properties:Polyurethane resins are known for their flexibility, making them suitable for applications where vibration and thermal cycling are concerns. They offer good moisture resistance and are often used in outdoor applications.

- Applications:Polyurethane resins are commonly used in LED drivers, sensors, and marine electronics.

- Silicone Resins

- Properties:Silicone resins are highly resistant to extreme high and low temperatures, making them ideal for applications in harsh environments. They also offer excellent electrical insulation properties and flexibility.

- Applications:Silicone resins are used in aerospace electronics, automotive under-the-hood applications, and medical devices.

- Acrylic Resins

- Properties:Acrylic resins are known for their transparency and UV resistance. They are easy to apply and cure quickly, making them suitable for applications that require a quick turnaround.

- Applications:Acrylic resins are often used in LED encapsulation and other applications requiring clear potting.

Manufacturing Process of Potting Materials

Manufacturing potting materials involves several critical steps to ensure that the final product meets the stringent requirements of the industries it serves. Below is an overview of the manufacturing process:

- Raw Material Selection

- The process begins with selecting raw materials, which include various resins, curing agents, and additives. The choice of raw materials is crucial as it determines the properties of the final potting material, such as thermal conductivity, chemical resistance, and mechanical strength.

- Mixing

- Once the raw materials are selected, they are mixed in precise proportions to create the potting compound. The mixing process must be carefully controlled to ensure uniformity and consistency in the final product. Advanced mixing equipment is used to achieve a homogeneous mixture free from air bubbles or contaminants.

- Degassing

- After mixing, the compound undergoes a degassing process to remove any trapped air bubbles. Air bubbles can compromise the integrity of the potting material, leading to voids or weak spots that can reduce its protective capabilities.

- Formulation and Testing

- The mixed and degassed compound is then formulated into the desired potting material. This involves adding specific additives to enhance certain properties, such as flame retardancy or thermal conductivity. The formulation is rigorously tested to ensure it meets the required specifications.

- Packaging

- Once the potting material is formulated and tested, it is packaged in containers that prevent contamination and degradation. Packaging is critical, as exposure to air or moisture can affect the material’s performance.

Key Players in the Potting Material Manufacturing Industry

Several companies dominate the potting material manufacturing industry, each offering various products tailored to different applications. Some of the key players include:

- Henkel AG & Co. KGaA

- Henkel is a global leader in adhesives and sealants, including potting materials. Their range of Loctite potting compounds is widely used in automotive, aerospace, and industrial applications.

- 3M Company

- 3M offers a variety of potting and encapsulating materials designed for electronic protection. Their products are known for their reliability and performance in demanding environments.

- Dow Inc.

- Dow is a leading manufacturer of silicone-based potting materials. Their products are used in various industries, including automotive, aerospace, and consumer electronics.

- Master Bond Inc.

- Master Bond specializes in high-performance potting and encapsulating materials. Their products are designed for challenging applications where durability and reliability are critical.

- Huntsman Corporation

- Huntsman offers a wide range of polyurethane and epoxy-based potting compounds. These versatile materials are used in various industries, including automotive, electronics, and construction.

Applications of Potting Materials

Potting materials are used in a wide range of industries to protect and enhance the performance of electronic components. Some of the most common applications include:

- Automotive Electronics

- Potting materials protect electronic control units (ECUs), sensors, and other critical vehicle components. The materials must withstand extreme temperatures, vibrations, and exposure to chemicals.

- Aerospace and Defense

- In the aerospace and defense industries, potting materials protect avionics, radar systems, and other sensitive electronics from harsh environmental conditions. The materials must be lightweight, durable, and resistant to extreme temperatures.

- Consumer Electronics

- Potting materials protect the internal components of consumer electronics, such as smartphones, tablets, and wearable devices. They help prevent damage from moisture, dust, and physical impact.

- Medical Devices

- Medical devices like pacemakers and imaging equipment rely on potting materials to protect their electronic components. The materials used must be biocompatible and resistant to sterilization processes.

- Renewable Energy

- In the renewable energy sector, potting materials protect the electronic components of solar panels, wind turbines, and battery storage systems. The materials must withstand exposure to the elements and provide long-term durability.

Challenges in Potting Material Manufacturing

The manufacturing of potting materials has its challenges. Some of the critical challenges faced by manufacturers include:

- Meeting Industry Standards

- Potting materials must meet stringent industry standards and regulations, particularly in sectors such as aerospace, automotive, and medical devices. Manufacturers must ensure their products comply with these standards to gain market acceptance.

- Environmental Concerns

- The production and disposal of potting materials can have environmental impacts. Manufacturers are increasingly focused on developing eco-friendly materials that reduce their carbon footprint and minimize environmental harm.

- Material Compatibility

- Potting materials must be compatible with the electronic components they encapsulate. Incompatibility can lead to delamination, poor adhesion, or reduced performance. Manufacturers must carefully select and test their materials to ensure compatibility.

- Cost

- The cost of raw materials and the manufacturing process can be significant. To remain competitive, manufacturers must balance the need for high-performance materials with cost considerations.

Future Trends in Potting Material Manufacturing

The potting material manufacturing industry continuously evolves, driven by technological advancements and changing market demands. Some of the future trends in the industry include:

- Development of Smart Potting Materials

- Researchers are developing intelligent potting materials that can provide real-time data on the condition of the encapsulated components. These materials could monitor temperature, stress, and moisture levels, allowing for predictive maintenance and improved reliability.

- Sustainability Initiatives

- As environmental concerns grow, manufacturers are focusing on developing sustainable potting materials. This includes using bio-based resins, reducing hazardous chemicals, and improving the recyclability of materials.

- Advanced Formulations for High-Performance Applications

- The demand for high-performance potting materials in aerospace, defense, and renewable energy industries is driving the development of advanced formulations. These materials will offer improved thermal conductivity, chemical resistance, and mechanical strength, meeting the needs of increasingly complex applications.

- Miniaturization of Electronic Components

- As electronic components continue to shrink, potting materials must evolve to provide adequate protection without adding bulk. Manufacturers are developing thinner, lighter potting materials that offer the same level of protection as traditional materials.

Conclusion

Potting material manufacturers play a vital role in the electronics industry by providing solutions that protect and enhance the performance of electronic components. The materials they produce are used in various applications, from automotive electronics to medical devices, and must meet stringent durability, reliability, and performance standards. As technology advances and environmental concerns grow, the industry is poised for continued innovation, with the development of intelligent, sustainable, and high-performance potting materials on the horizon. Whether protecting a critical sensor in an aerospace application or ensuring the longevity of a consumer electronic device, potting material manufacturers are at the forefront of innovation, delivering the materials that keep our world running smoothly.

For more about choosing the top potting material manufacturer: an in-depth exploration, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Potting Compound vs. Epoxy: A Comprehensive Comparison

- Potting Compound for PCB

- In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

- A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

- A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

- Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

- A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

- In-depth Analysis of the Reparability of Encapsulation Materials

- A Comprehensive Analysis of Post-Potting PCB Issues and the Repair and Rework of Potting Materials

- A Comprehensive Analysis of the Compatibility between Encapsulation Materials and PCBs: Exploration of Chemical Reactions and Their Impact on Performance