Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- Electronic Potting Material Manufacturer

- January 6, 2026

- Acrylic Conformal Coating, Ceramic Potting Compound, circuit board potting compound, conformal coating for pcb, conformal coating material, conformal coating pcb, conformal coating silicone, conformal coating waterproof, Connector Potting Compound, deepmaterial adhesive glue, deepmaterial potting compound, electric motor potting compound, electrical potting compound, Electronic Conformal Coating, electronic encapsulation, electronic encapsulation manufacturer, Electronic Encapsulation Market, electronic encapsulation supplier, Electronic Potting and Encapsulation, Electronic Potting and Encapsulation Resins, electronic potting compound, electronics adhesive glue, electronics encapsulation adhesive, electronics encapsulation epoxy adhesive, electronics encapsulation epoxy adhesive glue, electronics epoxy adhesive, encapsulation epoxy adhesive, epoxy encapsulation, epoxy encapsulation electronic components, epoxy encapsulation led, epoxy encapsulation meaning, epoxy encapsulation molding compound, epoxy potting compound, epoxy resin encapsulation, Flexible Potting Compound, industrial adhesive suppliers, Industrial Conformal Coating, LED Potting Compound, One Part Epoxy Adhesive, polyurethane potting compound, potting compound for electronics, potting compound for pcb, silicone epoxy adhesive glue, UV curing potting compound, waterproof potting compound

Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

The modern automobile has undergone a radical transformation, evolving from a predominantly mechanical machine to a sophisticated network of electronic systems. Today’s vehicles are rolling data centers, integrating dozens of electronic control units (ECUs), advanced driver-assistance systems (ADAS), sophisticated infotainment, and, increasingly, full electric vehicle (EV) powertrains. At the heart of this revolution lies a critical, often unsung hero: electronic encapsulation. This process is not merely about packaging; it is a fundamental engineering discipline that ensures the durability, reliability, and longevity of automotive electronics in some of the most hostile environments imaginable.

The Crucible: Why Automotive Electronics Demand Robust Protection

Automotive electronics operate in a uniquely challenging arena. Unlike consumer electronics, which reside in climate-controlled environments, vehicle components must survive a relentless onslaught of stressors:

- Thermal Cycling: Components under the hood can experience temperatures from -40°C in winter to over 150°C near the engine or exhaust. This constant expansion and contraction can fatigue solder joints, crack components, and delaminate circuit boards.

- Mechanical Stress: Vibration from the road, shocks from potholes, and general acoustic noise can lead to fretting corrosion, broken wires, and cracked ceramic components.

- Chemical Exposure: Electronics are exposed to fuels, oils, brake fluids, coolant, road salts, and de-icing agents. These chemicals can corrode metal traces and connectors.

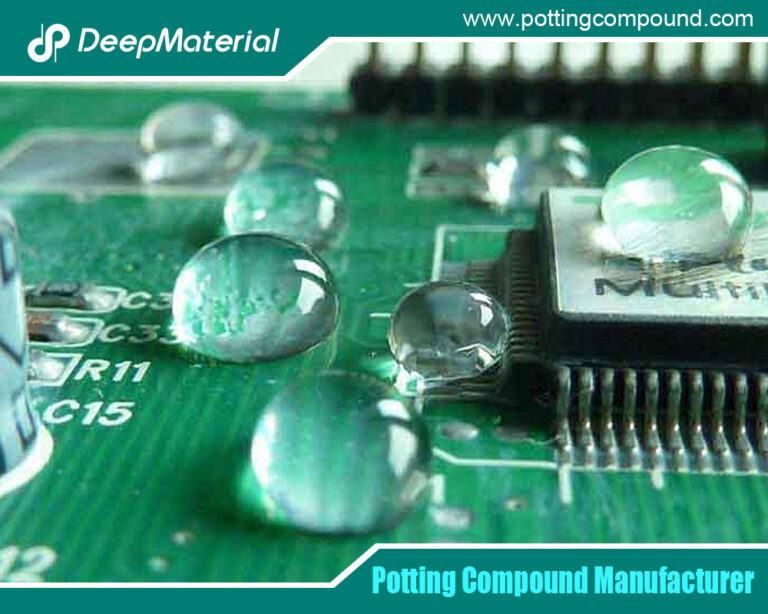

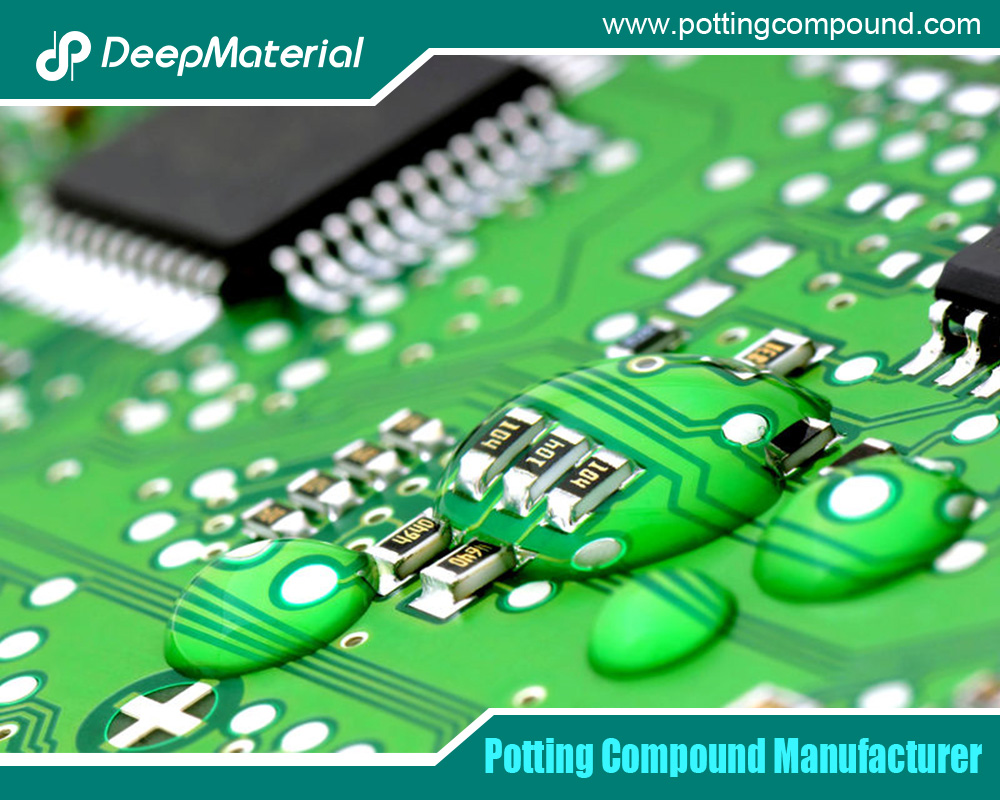

- Moisture and Humidity: Condensation, washing, and driving in rain introduce moisture, which can cause short circuits, electrochemical migration, and corrosion. The threat is especially acute with constant humidity cycling.

- Contaminants: Dust, sand, and other particulate matter can interfere with connectors, clog sensors, and cause abrasion.

- Electrical Stress: High-voltage environments in EVs (up to 800V and beyond) present significant risks of corona discharge, partial discharge, and tracking, which can degrade insulating materials over time.

Failure in any critical system—from braking and steering to battery management—is not an option. Encapsulation is the primary line of defense, creating a fortified micro-environment for delicate silicon and circuitry.

The Role of Encapsulation: More Than Just a Coating

Electronic encapsulation, or potting, involves enveloping an electronic assembly in a solid or gelatinous compound. Its functions are multifaceted:

- Environmental Sealing: Provides a hermetic or near-hermetic barrier against moisture, fluids, and contaminants.

- Mechanical Stabilization: Acts as a shock absorber, dampening vibration and preventing movement of components and wires. It distributes mechanical stress across the entire assembly, protecting brittle elements.

- Thermal Management: Many modern encapsulants are engineered to possess good thermal conductivity. They help transfer heat away from high-power components (e.g., power MOSFETs, regulators) to the module housing or heat sink, while also providing protection against thermal shock.

- Electrical Insulation: Enhances dielectric strength, prevents arc-over and tracking in high-voltage applications, and eliminates the risk of short circuits from conductive contaminants or moisture.

- Improved Reliability: By mitigating the primary failure mechanisms, encapsulation dramatically extends the operational lifespan of electronic modules, directly contributing to vehicle warranty periods and long-term customer satisfaction.

Materials Science at Work: Choosing the Right Encapsulant

Selecting the appropriate encapsulant material is a critical design decision, balancing performance requirements with manufacturability and cost. The three dominant chemistries in automotive applications are:

- Epoxy Resins:

- Properties: High rigidity, excellent chemical and moisture resistance, superior adhesion to most substrates, and good high-temperature performance.

- Applications: Ideal for sensors, under-hood ECUs, and components where maximum dimensional stability and hard shell protection are needed. They are often used in transfer molding processes for high-volume production like ignition modules and microprocessors.

- Durability Contribution: Their robust nature provides outstanding protection against solvents and mechanical abrasion. However, their rigidity can be a drawback in high-flex or high-thermal-cycle applications if not formulated correctly, as they may transfer stress to solder joints.

- Silicone Elastomers:

- Properties: Exceptional flexibility across a wide temperature range (-50°C to 200°C+), excellent thermal stability, superb electrical insulation properties, and inherent hydrophobicity.

- Applications: The gold standard for high-reliability and extreme environments. Used in EV battery management systems (BMS), power inverters, LED lighting, and sensors exposed to extreme thermal cycling. Their soft, rubbery consistency provides excellent stress relief.

- Durability Contribution: Silicones excel in managing thermal expansion mismatch. They “decouple” components from the housing, allowing for movement without inducing stress. Their UV and ozone resistance also makes them suitable for exposed applications.

- Polyurethanes (PU):

- Properties: A balance between epoxy hardness and silicone softness. They offer good moisture resistance, low viscosity for easy processing, and decent flexibility.

- Applications: Commonly used for potting cable harness connectors, smaller ECUs, and components where some degree of reworkability is desired (though fully cured PUs can be difficult to remove).

- Durability Contribution: Provide a tough, abrasion-resistant barrier with good damping characteristics for vibration. They are a cost-effective solution for many mid-range durability requirements.

Emerging and Specialized Materials:

- Thermally Conductive Encapsulants: Formulations filled with alumina, boron nitride, or other ceramics to enhance heat dissipation. Critical for high-power density modules in EVs.

- Low-Density Foams: Used for both encapsulation and thermal insulation in battery packs.

- Gap Fillers: Soft, putty-like materials used to fill air gaps between heat-generating components and housings, improving thermal pathway efficiency.

Application Techniques and Manufacturing Considerations

The application method significantly impacts the performance and consistency of the encapsulation:

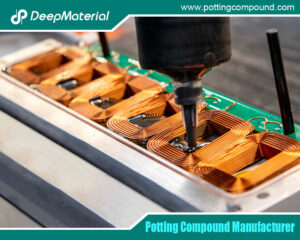

- Potting: The liquid encapsulant is dispensed into a housing containing the electronic assembly, completely surrounding it. This is the most common method for high-level protection.

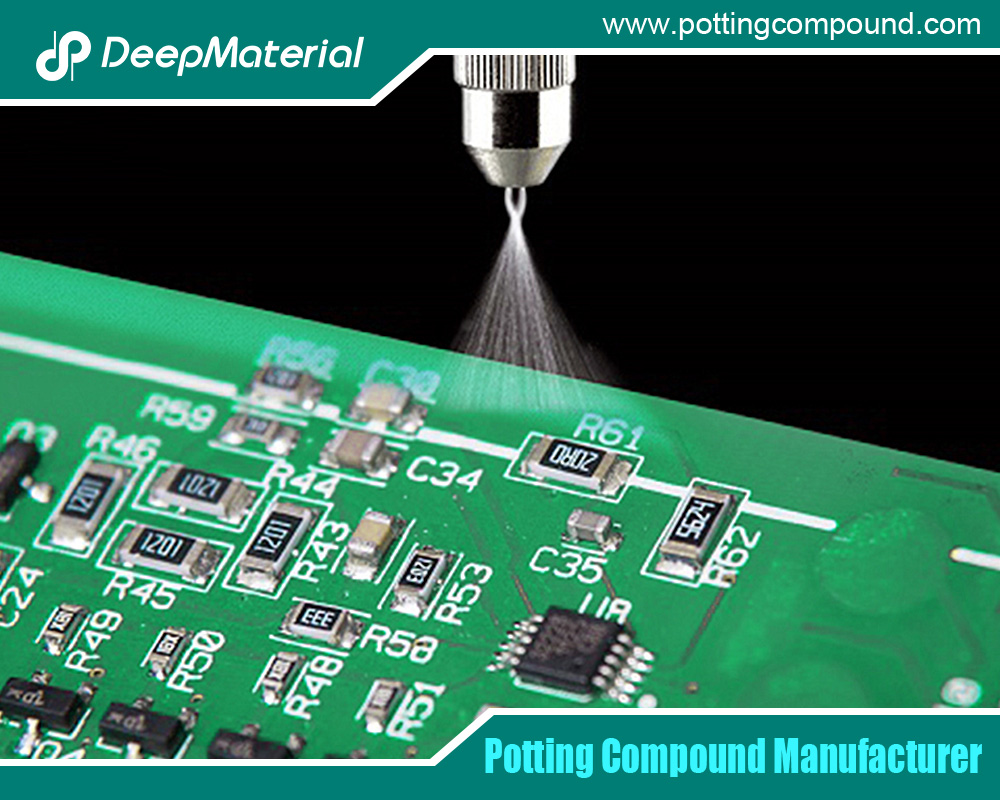

- Conformal Coating: A thin polymeric film (often acrylic, silicone, or polyurethane) is applied to the PCB, following its contours. It provides protection against moisture and contamination but less mechanical support. Often used for smaller, low-profile boards.

- Molding (Transfer/Compression): The electronic component is placed in a mold cavity, and the encapsulant (typically epoxy) is forced under pressure and heat to form a precise, hard shell around it. This is highly automated and consistent, perfect for high-volume components.

Manufacturing challenges include ensuring complete fill without air bubbles (voids), managing exothermic heat during cure, achieving adhesion to different materials (PCB, components, housing), and designing for potential rework or failure analysis.

Case Studies in Durability Enhancement

- Electric Vehicle Traction Inverter:

This unit converts DC battery power to AC for the drive motor. It operates at very high voltages and currents, generating significant heat. Encapsulation here serves a triple role:

- Electrical Insulation: Prevents corona discharge and arc faults between high-voltage terminals.

- Thermal Management: Thermally conductive silicone efficiently transfers heat from IGBT (Insulated-Gate Bipolar Transistor) modules to the cooling system.

- Mechanical Stabilization: Secures heavy busbars and power components against high-vibration environments. The encapsulation system is critical for achieving the required power density and 15+ year lifespan.

- Under-Hood Sensors (e.g., Camshaft, Crankshaft, Pressure Sensors):

Exposed to extreme temperatures, oil splash, and fuel vapors. A hard epoxy transfer mold provides a hermetic seal for the sensing element, protects the ASIC (Application-Specific Integrated Circuit), and ensures signal integrity in a electrically noisy environment. - ADAS and LiDAR Modules:

Mounted behind the windshield or in bumpers, these systems require absolute optical clarity and reliability. Encapsulation protects the delicate laser and receiver electronics from temperature-induced misalignment, humidity-induced fogging, and vibration, ensuring the system’s calibration and accuracy are maintained over the vehicle’s life.

Future Trends and Challenges

As automotive electronics advance, so too do encapsulation demands:

- Higher Power Density: The push for more compact, powerful electronics demands encapsulants with even better thermal conductivity.

- Wide-Bandgap Semiconductors: The adoption of SiC (Silicon Carbide) and GaN (Gallium Nitride) devices enables higher switching frequencies and temperatures, requiring encapsulants stable above 200°C.

- Autonomous Driving (Level 4/5): The “fail-operational” requirement means redundancy and unprecedented reliability. Encapsulation will be vital in creating robust, self-contained sensor and compute modules.

- Sustainability: There is growing pressure to develop bio-based, recyclable, or more easily removable encapsulants to support end-of-life vehicle recycling and a circular economy.

- Advanced Testing: Simulation and validation techniques (e.g., multi-physics modeling of stress, thermal, and fluid flow) are becoming essential to predict encapsulant performance before physical prototyping.

Conclusion

Electronic encapsulation is a cornerstone technology in the journey towards safer, more reliable, and more intelligent vehicles. It is a sophisticated interplay of materials science, process engineering, and design. By transforming vulnerable printed circuit boards into ruggedized, environmentally sealed modules, encapsulation directly enables the placement of critical electronics anywhere in the vehicle—from the scorching depths of the engine bay to the splash zones of the wheel wells.

As the automotive industry accelerates into an era defined by electrification and autonomy, the role of encapsulation will only grow in importance. The relentless pursuit of durability through advanced encapsulation is not just about protecting circuits; it is about safeguarding the very functionality that defines the modern driving experience and ensuring that the electronic heart of the automobile beats reliably for hundreds of thousands of miles, in all conditions, for years to come. The silent guardian of silicon, encapsulation is truly a key enabler of automotive innovation.

For more about electronic encapsulation technology to enhance the durability of automotive electronics, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB