How to Choose the Right Potting Material for Your PCB

- Electronic Potting Material Manufacturer

- January 22, 2026

- china electronic potting silicone supplier, circuit board potting, circuit board potting compound, circuit board potting compounds, Connector Potting Compound, Connector Potting Process, custom automated electronics potting, deepmaterial PCB Potting, deepmaterial potting compound, electrical potting compound, electronic encapsulant potting compounds, Electronic Encapsulation Market, electronic encapsulation supplier, Electronic Potting and Encapsulation, electronic potting material, electronics encapsulation epoxy adhesive, encapsulation epoxy adhesive, epoxy encapsulation electronic components, epoxy encapsulation led, epoxy encapsulation meaning, epoxy potting compound, Flexible Potting Compound, industrial adhesive suppliers, Industrial Conformal Coating, LED Potting Compound, One Part Epoxy Adhesive, PCB Potting Compound, PCB Potting Compound and Conformal Coating Adhesive, PCB potting compounds, PCB Potting Material, PCB potting material china hotsale, PCB potting material factory wholesale, PCB potting service, polyurethane potting compound, potting compound for electronics, potting compound for pcb, potting material, potting material for electronic, potting material for electronic components, potting material for electronic compounds, potting material for electronics, potting material manufacturers, Potting Materials for Electronics, silicone epoxy adhesive glue, UV curing potting compound

How to Choose the Right Potting Material for Your PCB

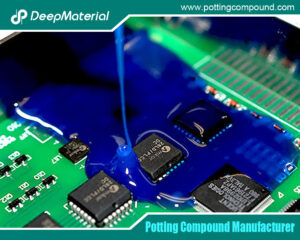

Printed Circuit Boards (PCBs) form the backbone of modern electronics, but their delicate copper traces and components remain vulnerable to environmental stresses. Potting—the process of applying a protective coating or potting compound—serves as the essential shield against moisture, chemicals, thermal cycling, mechanical shock, and contaminants. Choosing the wrong material can lead to premature failure, while the right selection enhances reliability, extends service life, and ensures performance in demanding conditions. This comprehensive guide examines the critical factors, material options, and selection methodology for PCB potting.

Understanding Potting: More Than Just Protection

PCB Potting, also referred to as potting or conformal coating, involves enveloping a PCB assembly in a protective polymeric material. Beyond basic protection, it provides:

- Electrical Insulation: Prevents short circuits from moisture or conductive dust.

- Thermal Management: Some materials aid in heat dissipation.

- Mechanical Stabilization: Anchors components, reducing stress on solder joints from vibration.

- Chemical Resistance: Shields against corrosive atmospheres.

- Environmental Sealing: Creates a barrier against humidity, salt spray, and pollutants.

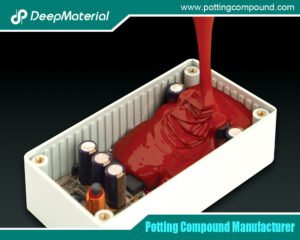

The Potting process can range from spraying a thin conformal coat to completely potting the assembly in a resin-filled enclosure.

Key Material Classes and Their Properties

- Silicones

Characteristics: Elastomeric, flexible, excellent high-temperature performance (-50°C to 200°C+).

Advantages:

- Outstanding thermal cycling resistance due to low modulus and high elasticity.

- Good moisture resistance and electrical properties.

- UV and ozone resistant.

- Relatively easy rework.

Disadvantages: - Lower mechanical strength.

- Can be permeable to gases.

- Often requires adhesion promoters.

Best For: High-temperature applications, flexible assemblies, environments with extreme thermal cycling (e.g., automotive under-hood, aerospace, LED lighting).

- Epoxies

Characteristics: Rigid, high-strength, excellent adhesion.

Advantages:

- Exceptional mechanical strength and hardness.

- Superior chemical and solvent resistance.

- Low shrinkage during cure.

- Excellent moisture barrier.

- Can be formulated with high thermal conductivity.

Disadvantages: - Brittle, prone to cracking under thermal stress.

- Difficult, often destructive, rework.

- Exothermic cure can damage heat-sensitive components.

Best For: High mechanical stress environments, applications requiring robust chemical resistance, and where structural rigidity is beneficial (e.g., industrial controls, down-hole electronics).

- Polyurethanes

Characteristics: Range from flexible to rigid, good toughness.

Advantages:

- Good moisture resistance.

- Excellent abrasion and vibration damping.

- Low-temperature flexibility.

- Moderate reworkability.

Disadvantages: - Sensitive to moisture during cure (can cause bubbling).

- Poor high-temperature performance (typically limited to ~125°C).

- Can degrade with prolonged heat exposure.

Best For: Applications subject to vibration and mechanical shock, outdoor environments with wide temperature swings (e.g., automotive sensors, marine electronics).

- Acrylics (Common for Conformal Coatings)

Characteristics: Fast curing, easy rework.

Advantages:

- Easy application and rapid cure.

- Excellent fungal resistance.

- Remarkably easy to rework with solvents.

- Good general-purpose moisture protection.

Disadvantages: - Lower chemical and solvent resistance.

- Can become brittle at low temperatures.

- Limited thermal endurance.

Best For: High-volume consumer electronics, commercial devices where repairability is a priority, and moderate environments.

- Parylene (Vapor-Deposited Polymer)

Characteristics: Ultra-thin, pinhole-free, conformal coating applied via vapor deposition.

Advantages:

- Extremely uniform, penetrating coating.

- Excellent dielectric strength and chemical barrier.

- Biocompatible and USP Class VI certified.

- Minimal added weight or dimension.

Disadvantages: - Very expensive process.

- Requires specialized deposition equipment.

- Difficult local rework.

Best For: Ultra-reliable, miniaturized, or implantable medical devices, military/aerospace electronics, harsh chemical environments.

Comparison Table: Key Material Properties

| Property | Silicone | Epoxy | Polyurethane | Acrylic |

| Flexibility | High | Rigid | Med-High | Low-Med |

| Max Temp | >200°C | ~150°C | ~125°C | ~130°C |

| Chem Resistance | Good | Excellent | Good | Fair |

| Moisture Barrier | Good | Excellent | Very Good | Good |

| Rework Ease | Moderate | Very Difficult | Moderate | Easy |

| Dielectric Strength | High | Very High | High | High |

| Thermal Conductivity | Low-Med | Can be High | Low | Low |

| Cost | Medium-High | Low-Med | Medium | Low |

The Selection Framework: 8 Critical Factors

- Operational Environment

This is the primary driver. Define all exposures:

- Temperature Range & Cycling: Consider both operating extremes and rates of change. Silicones excel in wide, rapid cycling.

- Humidity/Moisture: Continuous immersion vs. condensation. Epoxies provide the best barrier.

- Chemical Exposure: Industrial solvents, fuels, acids, or alkalis. Check chemical compatibility charts.

- Mechanical Stress: Constant vibration (damping needed – polyurethanes), occasional shock, or abrasion.

- Outdoor/UV Exposure: Requires UV-stable formulations (silicones, certain acrylics).

- Electrical Requirements

- Dielectric Strength: Critical for high-voltage applications (e.g., power supplies, EV components).

- Dielectric Constant & Loss Tangent: Important for high-frequency/RF circuits. Low Dk materials like some silicones minimize signal loss.

- Surface & Volume Resistivity: To prevent leakage currents.

- Thermal Management Needs

- Does the assembly generate significant heat? Thermally conductive formulations (epoxies and silicones filled with Al₂O₃, BN, or AlN) can help transfer heat to a heatsink or enclosure.

- Ensure the material’s Coefficient of Thermal Expansion (CTE) is somewhat matched to components and substrate to minimize stress.

- Physical & Mechanical Constraints

- Flexibility vs. Rigidity: Will the PCB bend? Will components with different CTEs cause stress? Flexible boards require elastomeric coatings (silicones, flexible urethanes).

- Weight Restrictions: Potting adds mass. Low-density foams or thin Parylene coatings are options.

- Optical Requirements: Some applications (LEDs, displays) need optically clear or light-diffusing materials.

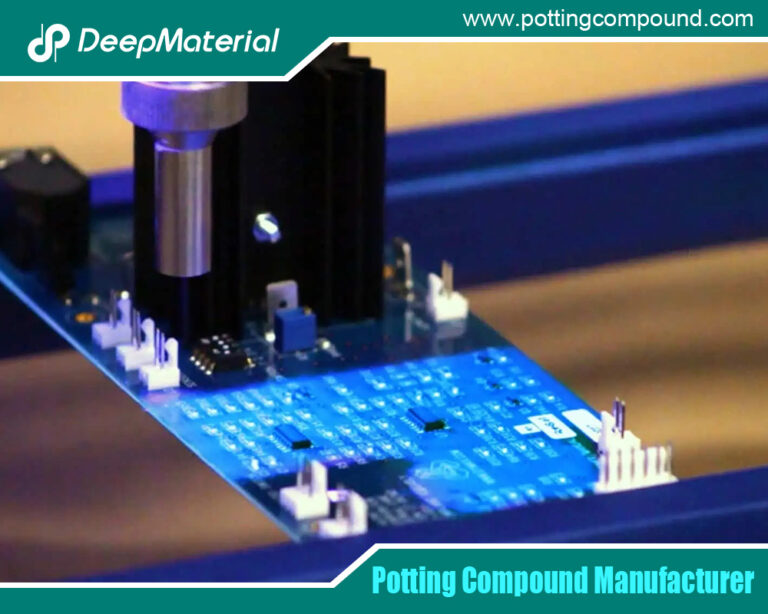

- Manufacturing & Lifecycle Considerations

- Cure Process: Time, temperature, and equipment. Room Temperature Vulcanizing (RTV) silicones are simple; heat-cure epoxies need ovens. UV-cure acrylics offer instant throughput.

- Pot Life: Working time of mixed resins. Critical for production line planning.

- Adhesion: To PCB substrate (FR4, polyimide), components, and connectors. Primers may be necessary.

- Reworkability & Repairability: Is the product intended to be serviced? Acrylics and some silicones allow component replacement; epoxies are typically permanent.

- Regulatory & Compliance Standards

- UL 94 Flammability Rating: Often required for consumer and industrial goods.

- IPC-CC-830: Standard for conformal coating qualification.

- Military Standards: Such as MIL-I-46058C (superseded but still referenced).

- Medical/Biocompatibility: ISO 10993 or USP Class VI for implants or devices contacting bodily fluids.

- RoHS/REACH: Restriction of hazardous substances.

- Cost Analysis (Total Applied Cost)

- Material cost per unit.

- Application cost: manual vs. automated dispensing, masking, curing equipment.

- Scrap and rework costs.

- Warranty and failure costs influenced by protection level.

- Long-Term Reliability & Testing

Never skip validation. Perform or require:

- Thermal Cycling: JEDEC, ASTM D4332.

- Temperature/Humidity Bias: 85°C/85% RH testing.

- Chemical Resistance Spot Tests.

- Vibration & Shock Testing: MIL-STD-810 or tailored profiles.

Application-Specific Recommendations

Industrial Motor Drives

- Environment: Vibration, occasional chemical splash, elevated temperatures.

- Choice: Filled Epoxy or Rigid Polyurethane. Provides structural rigidity, excellent environmental sealing, and good thermal conductivity to dissipate heat from power components.

Automotive Under-Hood Sensor

- Environment: -40°C to 150°C, constant thermal cycling, vibration, exposure to fuels and oils.

- Choice: Flexible Silicone. Its elastomeric nature accommodates CTE mismatches and relentless thermal cycles without cracking.

Consumer Drone Flight Controller

- Environment: Condensation, light vibration, need for light weight.

- Choice: Thin Acrylic Conformal Coating or Parylene. Provides essential moisture protection with minimal weight penalty. Acrylic allows easier field repair.

Implantable Medical Device

- Environment: 37°C, 100% humidity (body fluids), stringent biocompatibility.

- Choice: Medical-Grade Silicone or Parylene C. Both offer superb biocompatibility. Silicone for potting, Parylene for an ultra-thin, pinhole-free moisture barrier on sensitive microelectronics.

Maritime Communication Equipment

- Environment: High humidity, salt spray, UV exposure.

- Choice: Polyurethane Potting or Conformal Coating. Offers a strong balance of moisture resistance, salt spray resistance, and mechanical toughness. UV-stable formulations are available.

The Selection Process: A Practical Checklist

- Define Requirements Document: List all environmental, electrical, thermal, mechanical, and regulatory needs quantitatively.

- Narrow Material Class: Use the requirements to eliminate unsuitable classes (e.g., need for >150°C operation eliminates standard polyurethanes and acrylics).

- Source Candidate Formulations: Engage with technical representatives from reputable suppliers (Henkel, Dow, 3M, Electrolube, etc.). Provide them your requirements document.

- Request Samples & Data Sheets: Evaluate key properties: cure schedule, viscosity, CTE, Tg, dielectric properties, thermal conductivity.

- Perform Application Trials: Test application and cure on dummy boards. Check for flow around components, air release, and adhesion.

- Conduct Accelerated Life Testing: Subject encapsulated test boards to your most critical environmental stresses.

- Validate in Prototype: Build full functional prototypes and test under real-world or simulated conditions.

- Finalize Specification: Document the exact material manufacturer, product name, and version in your Bill of Materials (BOM). Avoid generic specs.

Common Pitfalls to Avoid

- Ignoring CTE Mismatch: A rigid epoxy on a large ceramic capacitor can crack it during thermal cycling.

- Overlooking Exothermic Cure: Potting a large volume with a fast-cure epoxy can generate enough heat to damage sensitive components.

- Sacrificing Repairability for Performance: Using a permanent epoxy on a high-value, serviceable board can turn a simple repair into a total loss.

- Inadequate Surface Preparation: Even the best material will fail if the PCB is contaminated with flux residues or oils. Always specify and follow a cleaning process.

- Forgetting Pot Life in Production: A 20-minute pot life might be fine for prototyping but impossible for a large batch production run.

Conclusion

Selecting the right PCB Potting material is a systematic engineering decision that balances performance, manufacturability, and cost. There is no universal “best” material—only the optimal choice for a specific set of conditions. By rigorously defining the operational environment, understanding the strengths and weaknesses of each material class, and validating the choice through testing, engineers can ensure their electronic assemblies achieve the reliability and longevity demanded by today’s applications. Start the selection process early in your design cycle, collaborate closely with material suppliers, and never underestimate the value of real-world testing. The invisible shield of Potting, when chosen correctly, becomes one of the most decisive factors in the success of your electronic product.

For more about how to choose the right potting material for your PCB, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?

- Usage Methods of LED Potting Compounds: From Mixing to Curing – A Complete Step-by-Step Guide