Why are Silicone Potting Compounds Used in Electronics Products?

Potting compounds are one of the key materials used to safeguard sensitive as well as critical electronics components from a variety of threats. Silicone-based potting compounds offer the maximum levels of elasticity and the least levels of mechanical strength. The global silicone potting compounds market is obtaining massive growth as they are one of the prime components of the electronics as well as automobile industries.

From tiny personal devices to huge ocean-going ships and automated industrial units, electronics is empowering the world to enhance people’s lives worldwide and develop improved products as well as services, which are required to be properly secured. Resilient and correctly protected electronic products are the key to contradicting global warming and averting climate changes for a viable future ahead. Potting compounds are at the forefront of an electronics assembly, providing proper protection in tough environmental situations while enhancing mechanical strength and providing better electric insulation. Electrical potting compounds are being used in a diversity of industrial sectors in an extensive range of consumer electronic products, as well as used in areas such as aerospace, automotive, and other sectors where electronics assemblies are predominant.

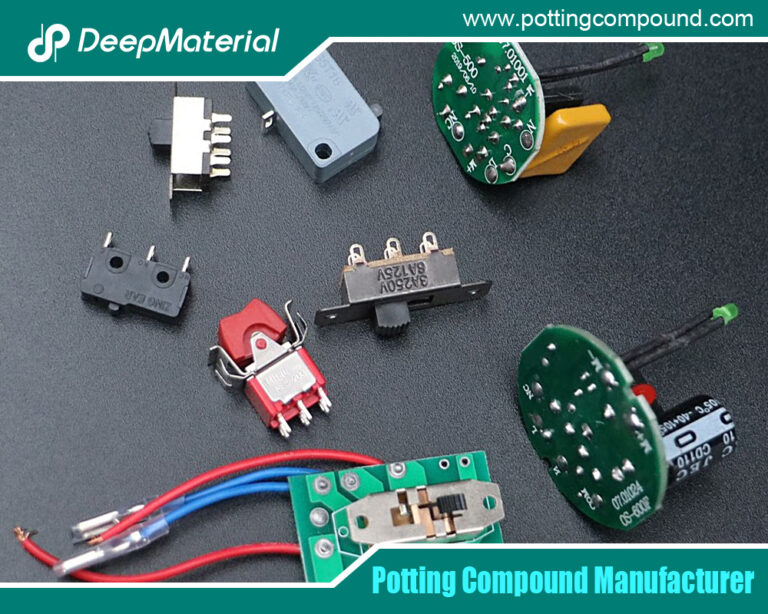

Potting compounds are one of the key materials used to safeguard sensitive as well as critical electronic components from a variety of threats, for example: severe environmental and climatic circumstances, vibrations, corrosive chemical aggression, dust, contact with heat and fire, etc.

Potting is the procedure of filling (completely or partly) or embedding the electronics components or assembly in an enclosure with a resinous material like silicone for offering better safety. The application of potting compounds can also help in improving electrical insulation, flame retardancy, as well as dissipation of heat. Potting compounds used in electronics are a permanent shielding aid which will endure to be as a vital player of the unit to safeguard the electronic assembly, while providing numerous benefits.

The key reason for making use of potting compounds rather than using different types of sealants is to safeguard against moisture to avoid short circuits, to provide augmented chemical protection in intricate assemblies, to offer resistance against mechanical shock and vibrations in severe environmental circumstances, and lastly, to offer concealment of the intellectual assets seized inside highly developed electric circuit.

Why Silicone-Based Potting Compounds are the Prime Choice of Electronics Manufacturers?

The demand for silicone potting compounds is surging among electronics manufacturers owing to the various benefits it offers for an electric assembly. As per a report by Research Dive, the global silicone potting compounds market is foreseen to grow with a CAGR of 4.5%, and garner $1,267.6 million by 2028.

Silicone potting compounds possess an exclusive blend of flexibility, high & low temperature resistance, while upholding mechanical properties in a broad array of temperature.

Silicone is a soft and flexible material with great elongation, which makes it appropriate for sealing sensitive electronic components. Silicone gels are usually used for highly sensitive units and they enable easy repairing.

Silicone-based potting compounds offer the maximum levels of elasticity and the least levels of mechanical strength, however, they are highly temperature resistant and provide working temperatures of around 200°c degrees. The global silicone potting compounds market is obtaining massive growth as they are one of the prime components of the electronics as well as automobile industries. These compounds provide protection against environmental factors like corrosion owing to water ingress, moisture, or security from caustic chemicals & gases. Moreover, these type of potting compounds possess unique characteristics than other potting compounds like epoxies potting compounds and urethanes potting compounds. For example, silicone potting compounds provide easy maintenance as silicone can be effortlessly detached from any component. They offer extensive temperature resistance for a range of about 50°F to 400°F. These compounds offer UV resistance mainly where electronic devices are exposed to the sun directly. Owing to this, cracking or yellowing of electric components is prevented. In addition, silicone-based potting compounds are highly recommended for industries who wish to avoid labour and compliance problems. These potting compounds have viscosity similar to fluids owing to which they are stress-free to pot as compared to other materials under the same circumstances, which makes them a highly opted potting compound among manufacturers.

Recent Posts

- The Potting and Encapsulating Compounds Market: An In-Depth Exploration of Trends, Innovations, and Future Prospects

- The Comprehensive Guide to Polyurethane Potting Compound Manufacturers

- The Comprehensive Guide to Epoxy Potting Compound Manufacturers

- The Essential Guide to Potting Materials for Electronics

- The Expanding Horizon of the Mini Silicone Optical Glue Market

- The Comprehensive Guide to PCB Potting Services: Ensuring Reliability in Electronics

- Comprehensive Insights on PCB Encapsulation in Potting Material

- The Vital Role of Industrial Silicone Adhesive Manufacturers in Modern Industry

- The Potting Material Manufacturer: Essential Players in Electronics Protection

- Exploring the Role of Electronic Encapsulation in Potting Material Manufacturing

Tags

Related Posts

The Comprehensive Guide to Epoxy Potting Compound Manufacturers

The Essential Guide to Potting Materials for Electronics

The Expanding Horizon of the Mini Silicone Optical Glue Market