Silicone Potting Compound Manufacturers: A Comprehensive Overview of Innovations, Applications, and Industry Trends

- Electronic Potting Material Manufacturer

- November 5, 2024

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting compound, Connector Potting Compound, deepmaterial potting compound, electrical potting compound, Electronic Encapsulant Potting Compound, Electronic Epoxy Encapsulant Potting Compound, electronic epoxy encapsulant potting compounds, Electronic Epoxy Potting Compound, electronic potting compound, Electronic Potting Compound Market, electronic potting compounds, Electronic Potting Compounds Manufacturer, Encapsulant Potting Compound, Encapsulants and Potting Compounds Suppliers, Epoxy Encapsulant Potting Compound, Industrial Conformal Coating, pcb conformal coating, potting compound manufacturer, Silicone Conformal Coating, Silicone Potting Compound, silicone potting compound for electronics, Silicone Potting Compound Manufacturer, Urethane Conformal Coating, UV Cure Conformal Coating, Waterproof Conformal Coating

Silicone Potting Compound Manufacturers: A Comprehensive Overview of Innovations, Applications, and Industry Trends

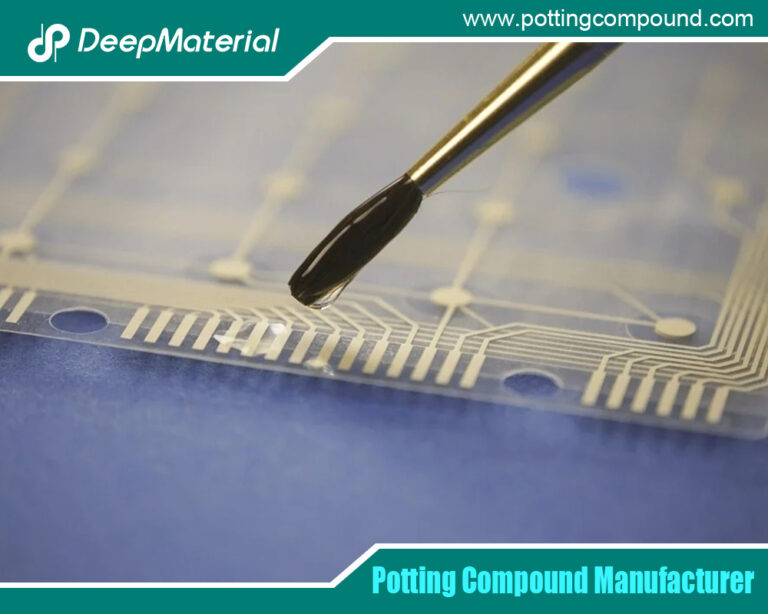

Silicone potting compounds are essential materials used in various applications, primarily electronics. These compounds protect sensitive electronic components critically against environmental factors such as moisture, dust, and chemicals. The increasing demand for reliable and durable encapsulation materials has led to the emergence of numerous manufacturers specializing in silicone potting compounds. This blog post explores silicone potting compound manufacturers‘ innovations, applications, challenges, and future trends.

What Are Silicone Potting Compounds?

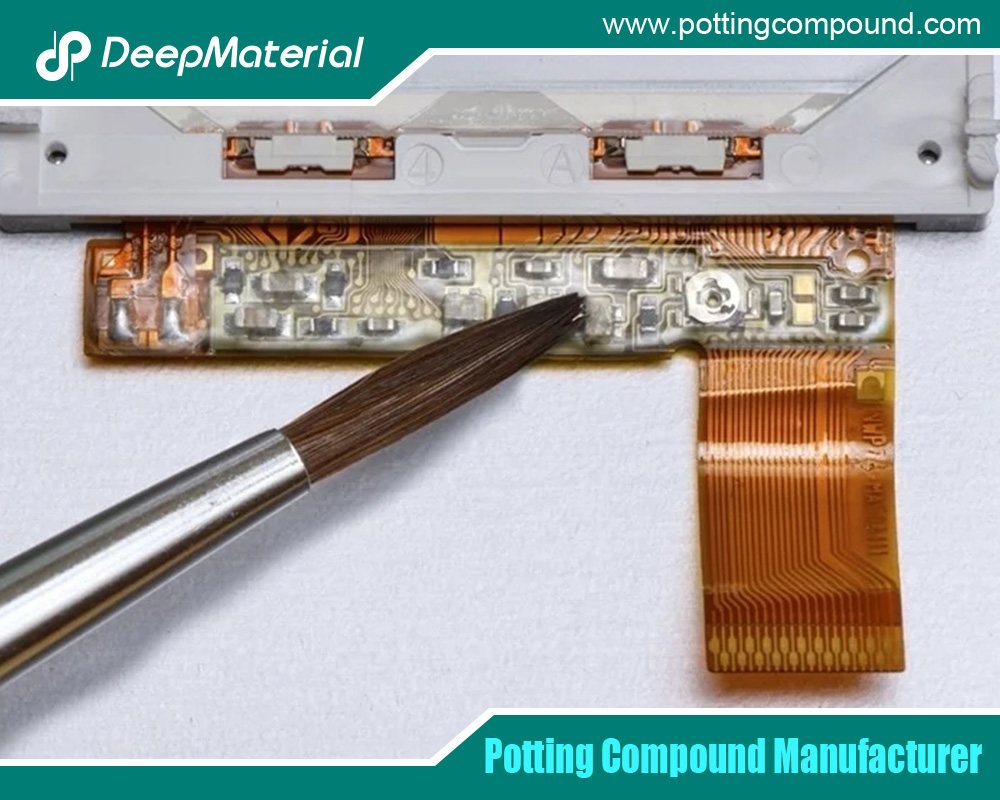

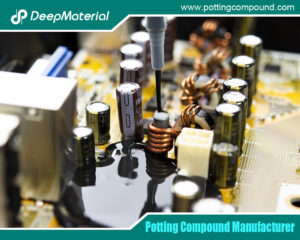

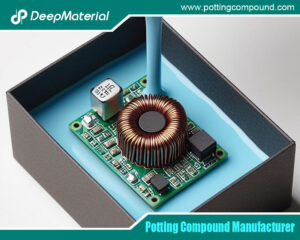

Silicone potting compounds are viscous materials encapsulating electronic components and assemblies, offering a protective barrier against environmental hazards. They cure into a solid form, providing mechanical support, electrical insulation, and thermal stability.

Critical Properties of Silicone Potting Compounds

- Moisture Resistance:Silicone potting compounds protect against moisture ingress, safeguarding electronic components from corrosion and damage.

- Thermal Stability:They maintain performance in extreme temperature conditions, making them suitable for heat generation applications.

- Electrical Insulation:Silicone offers high dielectric strength, ensuring reliable electrical performance and preventing short circuits.

- Flexibility:Unlike rigid materials, silicone remains flexible even after curing, allowing it to accommodate movement and thermal expansion.

- Chemical Resistance:Silicone potting compounds resist degradation when exposed to various chemicals, enhancing the longevity of encapsulated components.

Applications of Silicone Potting Compounds

Due to their protective properties and performance capabilities, silicone potting compounds are used across various industries. Below are some of the most common applications:

Electronics

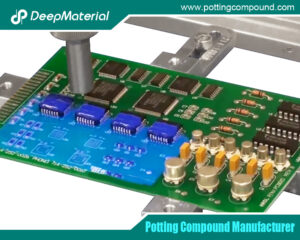

- Protective Encapsulation:Silicone potting compounds are widely used to encapsulate circuit boards, connectors, and sensors, protecting them from moisture, dust, and chemicals.

- Thermal Management:These compounds dissipate heat generated by electronic components, improving performance and reliability.

Automotive

- Component Protection:Silicone potting compounds protect sensitive automotive electronics from environmental factors such as humidity, temperature fluctuations, and vibrations.

- Vibration Damping:They help reduce the impact of vibrations on critical components, enhancing durability and reliability.

Aerospace

- Sealing and Insulation:Silicone potting compounds provide insulation for electronic systems in harsh aerospace environments, protecting against moisture and thermal fluctuations.

- Lightweight Solutions: The lightweight nature of silicone compounds contributes to weight reduction in aircraft components, improving fuel efficiency.

Medical Devices

- Biocompatibility:Silicone potting compounds are often used in medical devices due to their biocompatible properties, which ensure patient safety.

- Moisture Protection:They ensure the reliability of sensitive medical electronics by protecting against moisture ingress.

Renewable Energy

- Solar Panels:Silicone potting compounds protect electronic components in solar energy systems from environmental factors, ensuring longevity and performance.

- Wind Turbines:They encapsulate sensors and controllers exposed to extreme conditions, enhancing reliability and durability.

Benefits of Using Silicone Potting Compounds

Silicone potting compounds offer numerous advantages for various applications, making them a popular choice among manufacturers:

- Long Lifespan:Silicone materials have excellent aging properties, ensuring long-term performance and reliability.

- Easy Application:Low-viscosity formulations allow easy mixing and application, reducing production time.

- Enhanced Protection:Silicone potting compounds provide superior protection against environmental factors, ensuring the longevity of encapsulated components.

- Versatile Formulations:Manufacturers offer a wide range of customizable formulations to meet specific needs, enhancing application versatility.

Challenges Faced by Silicone Potting Compound Manufacturers

While the silicone potting compound industry continues to grow, manufacturers face several challenges that can impact their operations:

Competition from Alternative Materials

- Epoxy Resins:Some manufacturers are shifting towards epoxy resins, which may offer lower costs and different performance characteristics.

- Polyurethane:Competing materials with similar protective properties may challenge silicone’s market share.

Regulatory Compliance

- Environmental Regulations:Manufacturers must navigate complex regulations regarding emissions and waste management.

- Material Safety Standards:Compliance with industry-specific safety standards is crucial for market acceptance and product reliability.

Cost Management

- Raw Material Costs:Fluctuating prices for raw materials can impact production costs and profit margins.

- R&D Investments:Continuous innovation and development require significant investments in research and development, which can strain resources.

Market Saturation

- Increased Competition:As more manufacturers enter the market, distinguishing products and maintaining market share becomes increasingly challenging.

- Price Pressure:Competition may lead to price wars, impacting profitability and sustainability for manufacturers.

The Future of Silicone Potting Compound Manufacturing

The silicone potting compound manufacturing landscape is rapidly evolving, driven by technological advancements, sustainability initiatives, and changing market dynamics. As industries increasingly rely on these compounds to protect against environmental challenges, manufacturers adapt to meet future demands.

Sustainability Initiatives

A significant trend in the silicone potting compound market is the focus on sustainability. Manufacturers are implementing practices aimed at reducing environmental impact.

- Eco-Friendly Formulations:Developing low-VOC (volatile organic compound) silicone potting compounds aim to minimize emissions during production, promoting more eco-friendly formulations.

- Recycling Programs:Initiatives aimed at recycling silicone materials and reducing waste, promoting a circular economy.

2. Technological Advancements

Innovation is at the forefront of the silicone potting compound industry, with new technologies enhancing performance and application.

- Innovative Materials:The emergence of intelligent potting compounds that can adapt to environmental changes provides real-time performance monitoring and represents a significant innovation in materials.

- Automation in Production:Increased automation in manufacturing processes to enhance efficiency, reduce costs, and improve product consistency.

Market Expansion

The market for silicone potting compounds is set for significant growth, particularly in emerging economies and new application areas.

- Emerging Markets:Growing industrial sectors in Asia-Pacific and Latin America are adopting advanced materials, driving demand for silicone potting compounds.

- New Applications:The expansion into sectors like renewable energy, automotive electrification, and the Internet of Things (IoT) highlights the increasing criticality of encapsulation solutions.

Customization and Specialty Products

Manufacturers are shifting towards offering more customized solutions and specialty products tailored to specific applications to remain competitive.

- Tailored Solutions:The development of customizable silicone potting compounds aims to meet the unique requirements of diverse industries and applications, offering tailored solutions.

- Specialty Compounds:There is an increased focus on creating specialty potting compounds for niche applications, such as medical devices and high-temperature environments.

Regulatory Compliance

As environmental regulations become more stringent, manufacturers must adapt to meet these standards.

- Material Safety Standards:Compliance with evolving safety regulations will be crucial for market acceptance and to avoid potential legal issues.

- Sustainable Manufacturing Practices: Implementing sustainable practices that align with regulatory frameworks will enhance brand reputation and customer trust.

Conclusion

Silicone potting compounds play a critical role in protecting and enhancing the performance of electronic components across various industries. As manufacturers continue to innovate and adapt to changing market demands, the future of silicone potting compounds appears promising. Industry professionals must understand the key players in the market, their products, and their challenges.

For more about choosing the Top Silicone Potting Compound Manufacturers: A Comprehensive Overview of Innovations, Applications, and Industry Trends, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Potting Compound vs. Epoxy: A Comprehensive Comparison

- Potting Compound for PCB

- In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

- A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

- A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

- Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

- A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

- In-depth Analysis of the Reparability of Encapsulation Materials

- A Comprehensive Analysis of Post-Potting PCB Issues and the Repair and Rework of Potting Materials

- A Comprehensive Analysis of the Compatibility between Encapsulation Materials and PCBs: Exploration of Chemical Reactions and Their Impact on Performance