Self-Contained Fire Suppression Material Manufacturer: An In-depth Overview

- Electronic Potting Material Manufacturer

- September 26, 2024

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating material, conformal coating overspray, conformal coating pcb, conformal coating silicone, Connector Potting Compound, Electronic Conformal Coating, electronic potting compound, epoxy conformal coating, epoxy potting compound, Flexible Potting Compound, Industrial Conformal Coating, LED Potting Compound, pcb conformal coating, PCB Potting Compound, polyurethane potting compound, self-contained fire suppression material, self-contained fire suppression material manufacturer, Silicone Conformal Coating, Silicone Potting Compound, Urethane Conformal Coating, UV Cure Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating, waterproof potting compound

Self-Contained Fire Suppression Material Manufacturer: An In-depth Overview

Introduction to Self-Contained Fire Suppression Systems

Fire is a significant threat in various industrial, commercial, and residential environments. Traditional fire suppression systems, such as sprinklers or fire extinguishers, have been essential in combating fires. However, the need for more efficient, reliable, and easy-to-install fire suppression methods has led to the development of self-contained fire suppression materials.

A self-contained fire suppression system is a pre-engineered unit that combines fire detection and suppression within a single package. These systems are particularly valuable in situations where space is limited and immediate response to fire incidents is crucial. Innovation in this field has led to the rise of specialized manufacturers who design, produce, and supply these advanced fire suppression materials. This article delves into the role of manufacturers in this sector, the technologies involved, and the benefits of self-contained fire suppression materials.

The Role of Manufacturers in the Fire Suppression Industry

Manufacturers of self-contained fire suppression materials play a critical role in the fire safety industry. They are responsible for researching, designing, and producing fire suppression systems that meet specific safety standards and regulations. These manufacturers focus on creating materials that effectively extinguish fires and ensure that these systems are reliable, easy to install, and maintain.

Research and Development (R&D)

The R&D phase is the backbone of innovation in the fire suppression industry. Manufacturers invest heavily in research to develop new materials and technologies that efficiently detect and suppress fires. This includes experimenting with different chemical compounds, understanding fire dynamics, and exploring new ways to integrate detection and suppression mechanisms into a single, compact unit.

For example, manufacturers might develop fire suppression materials that release a gas, foam, or powder when exposed to high temperatures, effectively smothering the fire without harming the surrounding environment. The development of environmentally friendly fire suppression materials is also a growing trend as manufacturers seek to minimize the ecological impact of their products.

Compliance with Safety Standards

Fire suppression material manufacturers must adhere to stringent safety standards and regulations. These standards are often set by national and international bodies such as the National Fire Protection Association (NFPA), Underwriters Laboratories (UL), and the European Union (EU). Compliance with these standards ensures the products are safe, reliable, and effective in real-world scenarios.

Manufacturers undergo rigorous testing and certification to ensure their fire suppression materials meet or exceed these safety standards. This includes testing for durability, effectiveness under different fire conditions, and the potential impact on human health and the environment.

Customization and Application-Specific Solutions

Manufacturers also play a vital role in providing customized solutions tailored to specific applications. Different environments require different fire suppression strategies. For example, the fire risks in a data center are vastly different from those in an industrial manufacturing plant. Manufacturers work closely with their clients to understand the unique fire risks they face and develop materials that provide optimal protection.

Customization can involve selecting the correct type of suppression agent (e.g., gas, foam, or powder), designing the system to fit within the available space, and ensuring compatibility with existing fire detection and alarm systems. The ability to provide application-specific solutions is a crucial differentiator for manufacturers in this industry.

Technologies in Self-Contained Fire Suppression Materials

The technology behind self-contained fire suppression materials is continually evolving, driven by advancements in material science, detection technologies, and system integration. Understanding these technologies is crucial to appreciating the capabilities of modern fire suppression systems.

Suppression Agents

The choice of suppression agent is one of the most critical aspects of a fire suppression system. Different agents are suitable for various types of fires, and manufacturers develop materials based on the specific needs of their clients. The most common suppression agents include:

- Clean Agents:These gaseous chemicals extinguish fires without leaving residue, making them ideal for protecting sensitive equipment like electronics and servers. Examples include FM-200, Novec 1230, and inert gases like nitrogen and argon.

- Foam Agents:Used primarily in environments with flammable liquids, foam agents create a barrier that smothers the fire and prevents the release of flammable vapors.

- Dry Chemicals:These powders, such as monoammonium phosphate, interrupt the chemical reaction of the fire and are effective against various types of fires, including Class A, B, and C.

- Water Mist:This technology uses fine water droplets to cool the fire and displace oxygen, effectively suppressing the fire while minimizing water damage.

Detection and Activation Mechanisms

Detection is a critical component of self-contained fire suppression systems. These systems typically incorporate automatic detection mechanisms that trigger the release of the suppression agent when a fire is detected. Standard detection methods include:

- Heat Sensors:These sensors detect the temperature rise associated with a fire and activate the suppression system once a certain threshold is reached.

- Smoke Detectors:Optical or ionization smoke detectors are often integrated into fire suppression systems, allowing for early detection of smoke particles.

- Flame Detectors:These sensors detect the presence of flames by analyzing the infrared or ultraviolet light emitted by a fire.

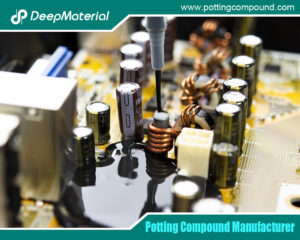

Once a fire is detected, the activation mechanism releases the suppression agent. This can be a simple mechanical release, such as a pressure valve opening, or a more complex electronic system that coordinates the release of multiple suppression agents across different zones.

Compact and Modular Designs

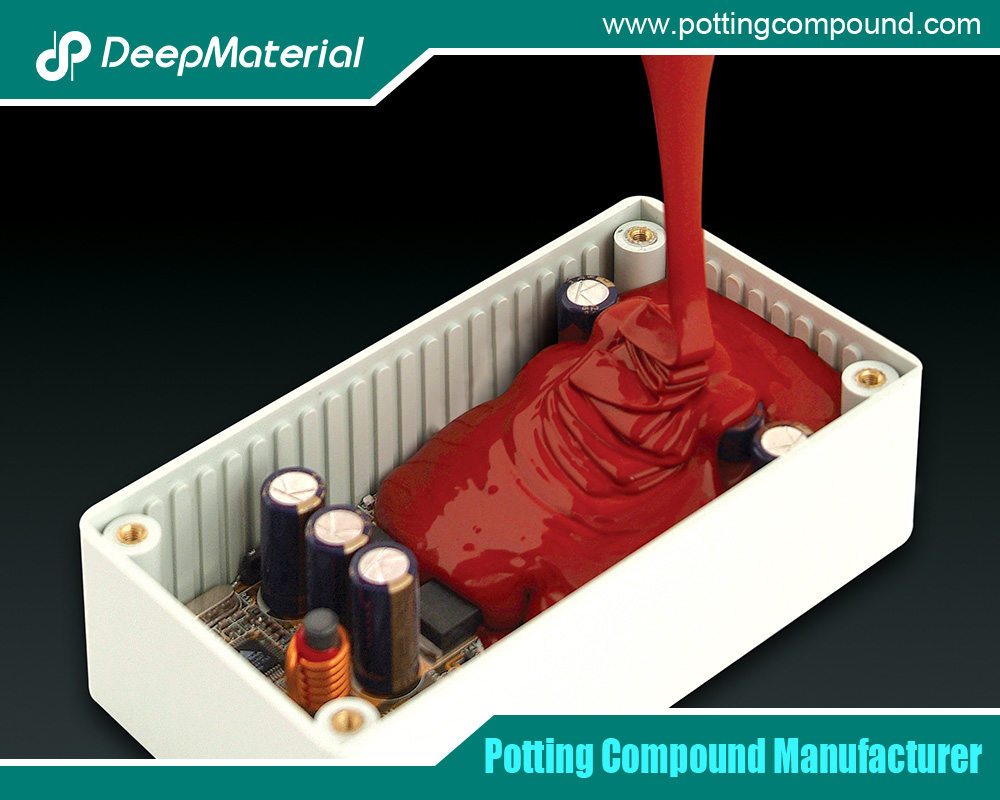

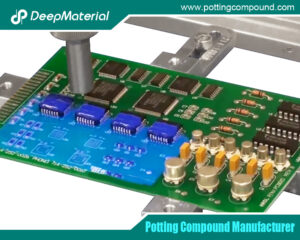

One of the defining features of self-contained fire suppression materials is their compact and modular design. Manufacturers have developed systems that are easily installed in tight spaces, such as electrical cabinets, server rooms, and small enclosures. The modular nature of these systems allows for scalability, meaning that additional units can be added as needed to protect larger areas or more complex environments.

Integrating detection, suppression, and activation mechanisms into a single unit reduces the need for extensive piping, wiring, and external control systems. This not only simplifies installation but also reduces maintenance requirements and potential points of failure.

Benefits of Self-Contained Fire Suppression Materials

Self-contained fire suppression materials offer several advantages over traditional fire suppression systems. These benefits make them attractive for various applications, from industrial settings to commercial buildings.

Rapid Response Time

One of the most significant advantages of self-contained fire suppression systems is their rapid response time. Because detection and suppression are integrated into a single unit, these systems can activate almost immediately upon detecting a fire. This fast response is crucial in preventing the spread of fire, minimizing damage, and ensuring the safety of personnel and property.

Easy Installation and Maintenance

The compact and modular design of self-contained fire suppression materials makes them easy to install, even in challenging environments. Unlike traditional systems requiring extensive piping, ductwork, and external control systems, self-contained units can be installed with minimal disruption to existing infrastructure.

Maintenance is also simplified, as these systems typically require fewer components and are designed for long-term reliability. Many manufacturers offer systems with built-in diagnostics to monitor the unit’s health and alert maintenance personnel to potential issues before they become critical.

Versatility and Adaptability

Self-contained fire suppression materials are highly versatile and can be adapted to various applications. Whether protecting a small electrical cabinet or an entire data center, these systems can be customized to meet the environment’s specific needs. This adaptability makes them suitable for various industries, including telecommunications, oil and gas, manufacturing, and transportation.

Environmental Considerations

As environmental concerns become increasingly important, manufacturers are developing fire suppression materials that are both effective and environmentally friendly. Clean agents, for example, are designed to extinguish fires without leaving residue or harming the environment. Some manufacturers also focus on developing suppression agents with low global warming potential (GWP) and ozone depletion potential (ODP), aligning their products with international environmental standards.

Challenges and Future Trends

While self-contained fire suppression materials offer many benefits, manufacturers face several challenges in this industry. These challenges include the need for continuous innovation, the complexity of regulatory compliance, and the demand for cost-effective solutions.

Continuous Innovation

The fire suppression industry is highly competitive, and manufacturers must continuously innovate. This involves developing new materials and technologies and improving existing products to enhance their performance, reliability, and ease of use. Research into new suppression agents, more sensitive detection methods, and more compact designs are ongoing focus areas.

Regulatory Compliance

As mentioned earlier, manufacturers must comply with various safety standards and regulations. Keeping up with changing regulations and ensuring that products meet these standards can be complex and time-consuming. Manufacturers must invest in testing, certification, and quality control to ensure their products are safe and compliant.

Cost-Effective Solutions

While self-contained fire suppression systems offer many advantages, they can be more expensive than traditional ones. Manufacturers are challenged to develop cost-effective solutions that provide the same level of protection while remaining affordable for a broader range of customers. This may involve exploring new materials, production methods, or economies of scale to reduce costs without compromising quality.

Future Trends

Looking to the future, several trends are likely to shape the development of self-contained fire suppression materials. These include:

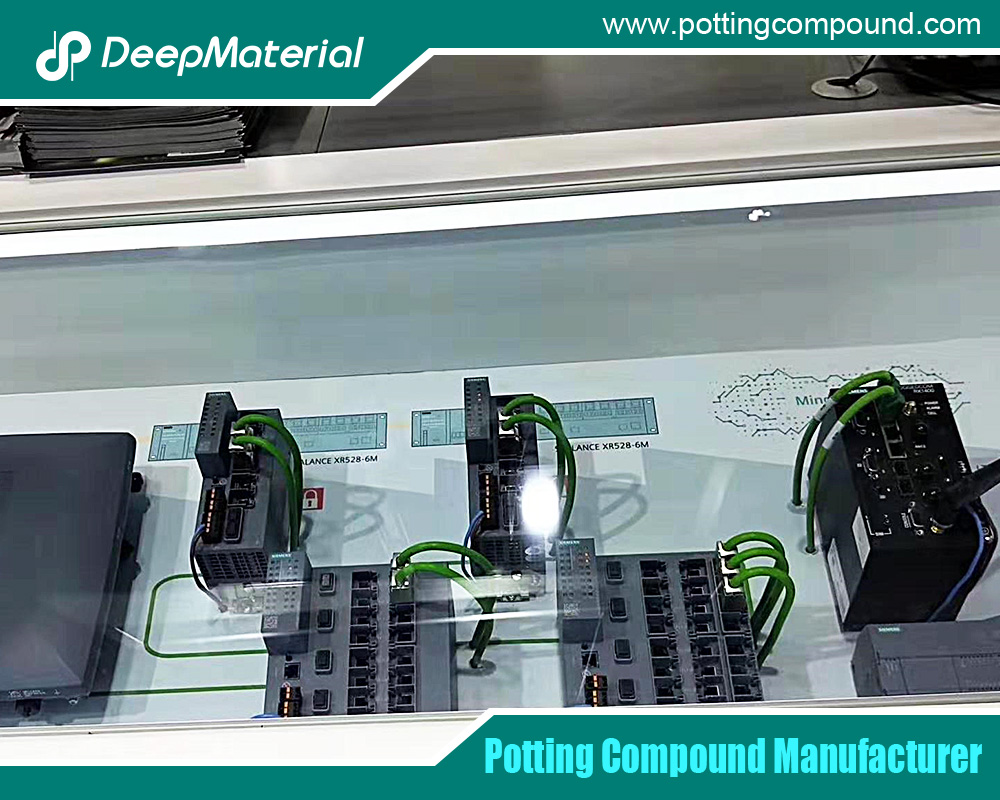

- Integration with Smart Building Systems:As buildings become more intelligent and connected, there is a growing trend toward integrating fire suppression systems with building management systems (BMS). This allows for centralized monitoring and control, enabling more efficient fire detection, response, and maintenance.

- Advancements in Detection Technology:The development of more sensitive and accurate detection methods is a crucial area of focus. This includes using artificial intelligence (AI) and machine learning to analyze sensor data and detect fires more quickly and accurately.

- Environmental Sustainability:As environmental regulations become stricter, manufacturers will continue to develop suppression agents and materials that are environmentally friendly. This includes reducing the environmental impact of production processes and exploring new materials with lower GWP and ODP.

- Miniaturization and Portability:The trend toward miniaturization and portability will continue, with manufacturers developing smaller, lighter, and more portable fire suppression units. These systems are suitable for various applications, including mobile and temporary installations.

Conclusion

Self-contained fire suppression material manufacturers play a vital role in the fire safety industry, providing innovative solutions that protect lives and property from the devastating effects of fire. Through continuous research and development, adherence to safety standards, and a focus on customization and application-specific solutions, these manufacturers have developed advanced fire suppression systems that offer rapid response, ease of installation, and environmental sustainability.

As the industry continues to evolve, manufacturers will face innovation, regulatory compliance, and cost-effectiveness challenges. However, with the ongoing development of new technologies and materials, the future of self-contained fire suppression systems looks promising. These systems will continue to play a crucial role in safeguarding various environments, from industrial facilities to commercial buildings, ensuring that fire risks are effectively managed and mitigated.

For more about choosing the best self-contained fire suppression material manufacturer: an in-depth overview, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Potting Compound vs. Epoxy: A Comprehensive Comparison

- Potting Compound for PCB

- In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

- A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

- A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

- Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

- A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

- In-depth Analysis of the Reparability of Encapsulation Materials

- A Comprehensive Analysis of Post-Potting PCB Issues and the Repair and Rework of Potting Materials

- A Comprehensive Analysis of the Compatibility between Encapsulation Materials and PCBs: Exploration of Chemical Reactions and Their Impact on Performance