Optically Clear Potting Compound: The Future of Electronics Protection

- Electronic Potting Material Manufacturer

- November 12, 2024

- Acrylic Conformal Coating, Connector Potting Compound, electronic potting compound, epoxy conformal coating, epoxy potting compound manufacturer, Flexible Potting Compound, Industrial Conformal Coating, LED Potting Compound, optically clear potting compound, optically clear potting compound china hotsale, optically clear potting compound China OEM, optically clear potting compound china wholesale, optically clear potting compound hotsale, optically clear potting compound supplier hotsale, optically clear potting compound supplier whlesale, Optically Clear Potting Compounds Manufacturer, Optically Clear Potting Compounds Manufacturer Hotsale, Optically Clear Potting Compounds Manufacturer Wholesale, PCB Potting Compound, Polyurethane Potting Compound Manufacturer, Silicone Conformal Coating, Silicone Potting Compound Manufacturer, Urethane Conformal Coating, UV Cure Potting Compound, Waterproof Conformal Coating, waterproof potting compound

Optically Clear Potting Compound: The Future of Electronics Protection

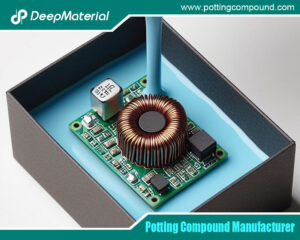

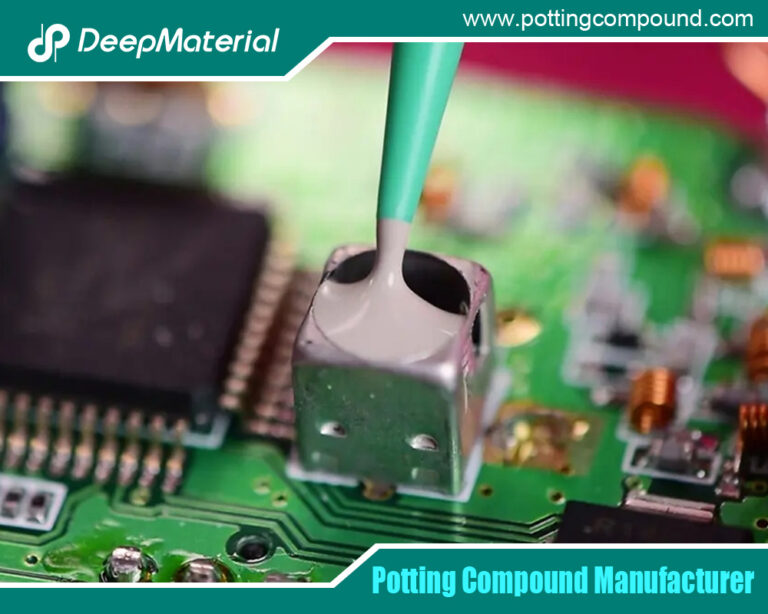

In the ever-evolving world of electronics, the demand for robust, efficient, and aesthetically pleasing devices has never been higher. With increasing miniaturization and integrating sensitive components, protecting these elements from environmental hazards such as moisture, dust, and mechanical stress is crucial. Optically apparent potting compounds have emerged as a vital solution for encapsulating electronic components, providing unparalleled protection while maintaining transparency. This blog post delves into the characteristics, benefits, applications, challenges, and future trends of optically clear potting compounds, offering a comprehensive overview of their significance in modern electronics protection.

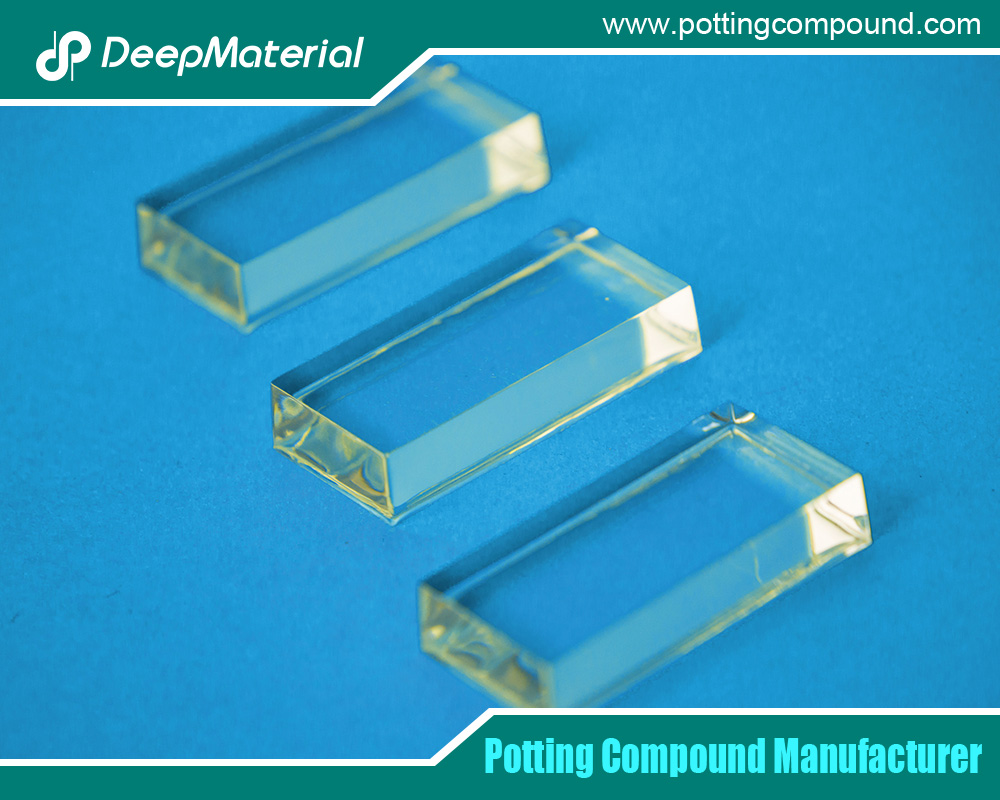

What is an Optically Clear Potting Compound?

Critical Properties of Optically Clear Potting Compounds

Optically apparent potting compounds possess several essential properties that make them ideal for electronic applications:

- Transparency:The precise formulation allows for easy inspection of encapsulated components, which is especially important in quality control processes.

- Excellent Adhesion:These compounds adhere strongly to various substrates, ensuring effective sealing against environmental threats.

- Durability:Optically apparent potting compounds offer high resistance to mechanical stress, chemicals, and thermal fluctuations, enhancing the longevity of encapsulated components.

- Electrical Insulation:They provide excellent electrical insulation, reducing the risk of short circuits and ensuring the safe operation of electronic devices.

- UV Resistance:Many optically clear compounds are formulated to resist UV degradation, making them suitable for outdoor applications where exposure to sunlight is a concern.

Benefits of Using Optically Clear Potting Compounds

Optically apparent potting compounds offer numerous advantages for electronic applications:

Enhanced Visibility

- Visual Inspection:These compounds’ transparency allows manufacturers and technicians to inspect solder joints and components without removing the potting material.

- Aesthetic Appeal:Clear potting compounds contribute to a sleek, modern design in consumer products, improving overall product attractiveness.

Robust Protection

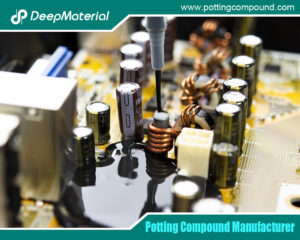

- Environmental Resistance:Optically apparent potting compounds protect electronic components from moisture, dust, and corrosive chemicals, ensuring reliability in harsh conditions.

- Shock Absorption:These compounds absorb mechanical shocks and vibrations, protecting delicate components from damage during operation.

Electrical Insulation

- Prevent Short Circuits:The excellent dielectric properties of optically clear potting compounds reduce the risk of electrical failures, enhancing the safety and reliability of electronic devices.

Versatile Applications

- Widely Applicable: Optically clear potting compounds suit various applications, including automotive, medical, aerospace, and consumer electronics.

Easy Application

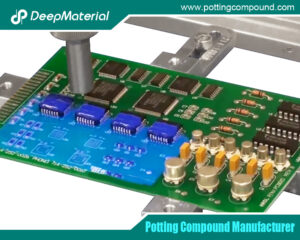

- Simple Processing:Many optically clear potting compounds are easy to mix and apply using methods such as pouring, dispensing, or injection, streamlining production processes.

Applications of Optically Clear Potting Compounds

Optically apparent potting compounds are utilized in various industries due to their protective and aesthetic properties. Key applications include:

Consumer Electronics

- LED Lighting: Used to encapsulate LED chips, ensuring durability and light transmission while protecting against moisture and dust.

- Smartphones and Tablets:Protects sensitive components while maintaining a sleek appearance.

Automotive Industry

- Headlights and Taillights:Optically apparent potting compounds encapsulate LED lighting systems, protecting them from the elements while allowing for bright illumination.

- Sensor Protection:Encapsulates automotive sensors to ensure they remain operational in harsh environments.

Medical Devices

- Diagnostic Equipment:Protects sensitive electronic components in medical devices from moisture and contamination while allowing for easy inspection.

- Wearable Devices:Ensures the durability and functionality of wearables while maintaining an appealing design.

Aerospace and Defense

- Avionics:Protects critical electronic systems from environmental hazards while allowing for visual inspection of components.

- Military Applications:Military electronics utilize specialized coatings to safeguard sensitive components from harsh conditions.

Challenges in Using Optically Clear Potting Compounds

Despite their many advantages, optically apparent potting compounds also come with some challenges:

- Curing Time:Some formulations may require longer, impacting production schedules and efficiency.

- Cost:High-quality optically apparent compounds can be more expensive than standard potting materials, potentially affecting project budgets.

- Thermal Expansion:Differences in thermal expansion rates between potting compounds and substrates can lead to stress, impacting the integrity of the encapsulated components.

- Chemical Compatibility:Not all optically clear compounds are compatible with every substrate, necessitating careful selection during the design phase.

Innovations in Optically Clear Potting Compound Formulations

Recent advancements in chemistry have led to the development of new formulations for optically clear potting compounds. These innovations include:

- Improved Flow Properties:Enhanced flow characteristics ensure even distribution during application, reducing the risk of air bubbles or voids.

- Faster Curing Times:New formulations offer accelerated curing processes, which can improve production efficiency and reduce bottlenecks.

Industry Standards and Regulations

With the increasing importance of reliability and safety in electronic devices, various industry standards and regulations govern the use of potting compounds. Manufacturers must ensure compliance with these standards, which may include:

- UL Ratings:Underwriters Laboratories (UL) certifies materials based on fire resistance, electrical insulation, and safety.

- RoHS Compliance:The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electronic products.

Market Dynamics

The optically clear potting compound market is influenced by several factors, including:

- Technological Advancements:Continuous improvements in material science and formulation technologies drive innovation in potting compounds.

- Consumer Demand:The push for more durable and aesthetically pleasing electronic devices leads to increased adoption of optically clear potting solutions.

- Global Supply Chain Factors: Market fluctuations, supply chain disruptions, and geopolitical issues can impact the availability and pricing of raw materials used in potting compounds.

Future Trends in Optically Clear Potting Compounds

The market for optically clear potting compounds is expected to evolve due to several trends:

Sustainable Solutions

- Eco-Friendly Formulations:As environmental concerns grow, manufacturers focus on developing potting compounds that minimize waste and reduce environmental impact.

- Biodegradable Options:Research is being conducted on biodegradable materials that offer the same protective qualities as traditional potting compounds.

Advanced Formulations

- Enhanced Properties:Ongoing research and development will likely yield optically clear compounds with improved thermal stability, electrical performance, and UV resistance.

- Nanotechnology Integration:Incorporating nanomaterials may enhance potting compounds’ mechanical and electrical properties.

Integration with Smart Technologies

- IoT Devices:The rise of intelligent electronics and IoT devices will drive demand for innovative potting solutions that protect without compromising functionality.

- Advanced Sensors:Optically apparent potting compounds protect complex electronic systems as sensor technology advances.

Customization and Tailored Solutions

- Industry-Specific Formulations:Manufacturers are increasingly focusing on providing customized formulations that meet the specific needs of various industries, enhancing their competitive edge.

- Application-Specific Solutions:Tailoring potting compounds for specific applications will improve performance and reliability in critical environments.

Conclusion

Optically apparent potting compounds protect and encapsulate electronic components while maintaining visibility and aesthetic appeal. With their excellent properties, such as transparency, durability, and electrical insulation, these compounds are well-suited for various applications in consumer electronics, automotive, medical devices, aerospace, and more.

For more about choosing the top optically clear potting compound: the future of electronics protection, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Potting Compound vs. Epoxy: A Comprehensive Comparison

- Potting Compound for PCB

- In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

- A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

- A Comprehensive Analysis of PCB Encapsulation Quality Inspection: Innovative Application of Non-Destructive Testing Technologies

- Analysis of the Improvement of the Seismic and Impact Resistance Performance of PCB by Encapsulation

- A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

- In-depth Analysis of the Reparability of Encapsulation Materials

- A Comprehensive Analysis of Post-Potting PCB Issues and the Repair and Rework of Potting Materials

- A Comprehensive Analysis of the Compatibility between Encapsulation Materials and PCBs: Exploration of Chemical Reactions and Their Impact on Performance