In-Depth Analysis of Several Common LED Potting Glue Types

- Electronic Potting Material Manufacturer

- October 28, 2025

- Automotive potting material manufacturers, Benefits of Potting Electronics, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, circuit board potting compound china hotsale, circuit board potting compound factory hotsale, circuit board potting compound factory wholesale, circuit board potting compound wholesale, circuit board potting compounds, conformal coating for electronics, conformal coating for pcb standards, conformal coating material, conformal coating silicone, conformal coating spray, Connector Potting Compound, Connector Potting Process, custom automated electronics potting, deepmaterial potting compound manufacturer, electric motor potting compound, electrical potting compound, LED Potting Glue, LED Potting Glue Manufacturer, LED Potting Glue Market, LED Potting Glue Supplier, LED Potting Glue Types, potting compound, potting compound for electronics, potting compound for pcb, potting compound vs epoxy, silicone potting compound for electronics, UV curing potting compound

In-Depth Analysis of Several Common LED Potting Glue Types

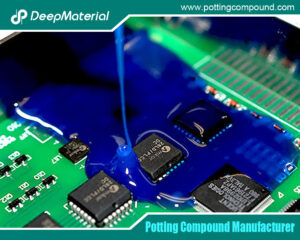

In the rapidly evolving world of LED technology, potting compounds play a crucial role in ensuring the longevity, reliability, and performance of LED assemblies. Potting involves encapsulating electronic components, such as LEDs, in a protective material to shield them from environmental hazards like moisture, dust, vibration, chemicals, and thermal stress. This process is essential in applications ranging from automotive lighting and outdoor displays to indoor illumination and medical devices, where LEDs must withstand harsh conditions while maintaining efficiency.

The choice of LED potting glue significantly impacts the final product’s durability, manufacturability, and cost. Common types include silicone potting compounds, epoxy potting compounds, polyurethane potting compounds, and UV-curable potting compounds. Each offers unique properties tailored to specific needs: silicones provide softness and elasticity for detachable applications with superior water and aging resistance; epoxies deliver hardness and rigidity for permanent, non-detachable bonds; polyurethanes offer elasticity with challenging detachability; and UV-curable compounds excel in shallow potting scenarios with high production efficiency.

This article explores these types in depth, examining their compositions, properties, advantages, disadvantages, and applications in LED manufacturing. By understanding these materials, engineers and manufacturers can make informed decisions to optimize LED performance and extend service life. Drawing from industry insights and technical data, we’ll highlight how these compounds address the demands of modern LED designs, including energy efficiency, miniaturization, and environmental compliance.

Silicone Potting Compounds

Silicone potting compounds are among the most versatile materials used in LED encapsulation, prized for their flexibility and resilience. Composed primarily of polydimethylsiloxane (PDMS) polymers, these compounds cure through addition or condensation reactions, often catalyzed by platinum or tin. In LED potting glue applications, they form a soft, rubber-like barrier that protects sensitive diodes from mechanical stress and environmental factors.

Key properties include exceptional thermal stability across a wide temperature range, typically from -100°C to over 200°C, making them ideal for LEDs in extreme environments like automotive headlights or outdoor signage. Their low modulus ensures minimal stress on delicate components during thermal expansion and contraction. Silicones are inherently hydrophobic, providing excellent water resistance that prevents moisture ingress, a common cause of LED failure. Additionally, they exhibit superior UV and aging resistance, maintaining clarity and integrity over time without yellowing or cracking.

Advantages of silicone potting compounds are numerous. Their softness and elasticity allow for easy detachment and rework, which is invaluable in prototyping or repair scenarios. This detachability reduces waste and facilitates component recycling, aligning with sustainable manufacturing practices. They also offer low outgassing, crucial for optical clarity in LED lenses, and good electrical insulation with dielectric strengths often exceeding 20 kV/mm.

In terms of processing, silicones have low viscosity for easy flow into intricate LED assemblies, and they cure at room temperature or with mild heat, minimizing energy use.However, disadvantages exist. Silicones are generally more expensive than epoxies or polyurethanes due to raw material costs. Their softness can be a drawback in applications requiring high mechanical strength or abrasion resistance, as they may not withstand heavy physical impacts. Adhesion to certain substrates, like some plastics, may require primers, adding to process complexity. Tin-cured silicones, while offering better adhesion, are limited in large-volume potting due to cure inhibition risks.

Applications in LEDs are widespread. In aerospace and automotive sectors, silicones encapsulate high-power LEDs to endure vibration and thermal cycling. For consumer electronics, they protect flexible LED strips from humidity. A case in point is their use in LED streetlights, where aging resistance ensures long-term lumen maintenance. Overall, silicones are the go-to for detachable, resilient potting in demanding LED setups.

Epoxy Potting Compounds

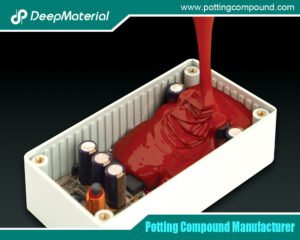

Epoxy potting compounds stand out for their robustness and permanence in LED protection. These thermosetting resins, typically bisphenol-A or novolac-based, cure via exothermic reactions between epoxy groups and hardeners like amines or anhydrides. In LED contexts, they create a hard, rigid shell that locks components in place, offering unmatched structural integrity.

Properties include high tensile strength (often 50-100 MPa) and modulus, ensuring rigidity that resists deformation under load. They excel in chemical resistance, shielding LEDs from solvents, acids, and alkalis in industrial environments. Thermal conductivity can be enhanced with fillers like alumina, aiding heat dissipation in high-brightness LEDs. Moisture resistance is excellent, with low water absorption rates (<0.5%), preventing corrosion of LED leads. Dielectric properties are strong, supporting high-voltage LED drivers.

Advantages lie in their superior adhesion to metals, ceramics, and glass without primers, simplifying assembly. High-temperature resistance (up to 180°C or more for heat-cured variants) suits power LEDs in lighting fixtures. Epoxies are cost-effective for high-volume production and provide flame retardancy in formulations meeting UL 94 V-0 standards. Their rigidity enhances shock and vibration protection, critical for automotive LEDs.

Disadvantages include non-detachability; once cured, removal often damages components, hindering repairs. Brittleness at low temperatures can lead to cracking during thermal shocks. Cure times vary—room-temperature types take 24-48 hours, while heat-cured require ovens, increasing energy costs. High exotherm during curing may stress sensitive LEDs if not managed.

In LED applications, epoxies pot transformers and drivers in displays, ensuring longevity in humid settings like aquariums or greenhouses. They are favored for structural potting in LED modules for signage, where rigidity prevents delamination. Specialty types, like thermally conductive epoxies, are used in high-power LED arrays for efficient cooling.

Polyurethane Potting Compounds

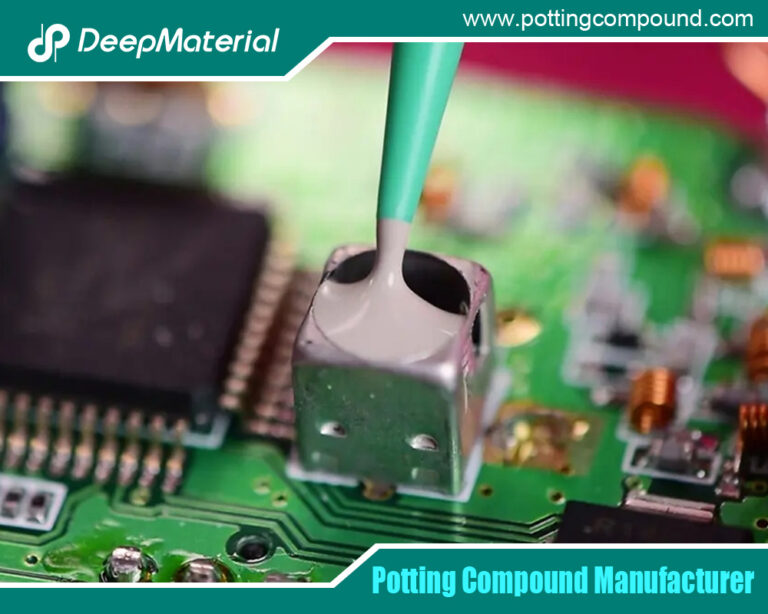

Polyurethane (PU) potting compounds bridge the gap between silicone’s flexibility and epoxy’s strength, offering elastic protection for LEDs. Formed from polyol and isocyanate reactions, they cure into elastomers with tunable hardness from soft gels to semi-rigid forms.

Properties feature high elongation (up to 500%) and flexibility, absorbing shocks and vibrations effectively. They operate in temperatures from -40°C to 105°C (extendable to -70°C to 135°C in specialties), suitable for most LED uses. Good moisture and chemical resistance protect against humidity and mild corrosives. Abrasion resistance is notable, and they exhibit low exotherm during cure, reducing thermal stress.

Advantages include balanced mechanical properties—elastic yet strong—for thermal cycling in multi-material LED assemblies. Fast curing and easy processing lower production times, with customizable pot life. Cost-effectiveness makes them appealing for mid-range applications. Good adhesion to plastics and composites without extensive preparation.

Disadvantages: Elasticity makes detachment difficult, often requiring cutting or solvents, complicating repairs. Moisture sensitivity during storage necessitates nitrogen blanketing. Limited high-temperature performance compared to silicones or epoxies. Some formulations may yellow under UV exposure, affecting optical LEDs.

Applications in LEDs include potting flexible circuits in wearable lights, where elasticity accommodates bending. In automotive, PUs encapsulate LED taillights for vibration resistance. They are used in optically clear variants for displays needing visibility.

UV-Curable Potting Compounds

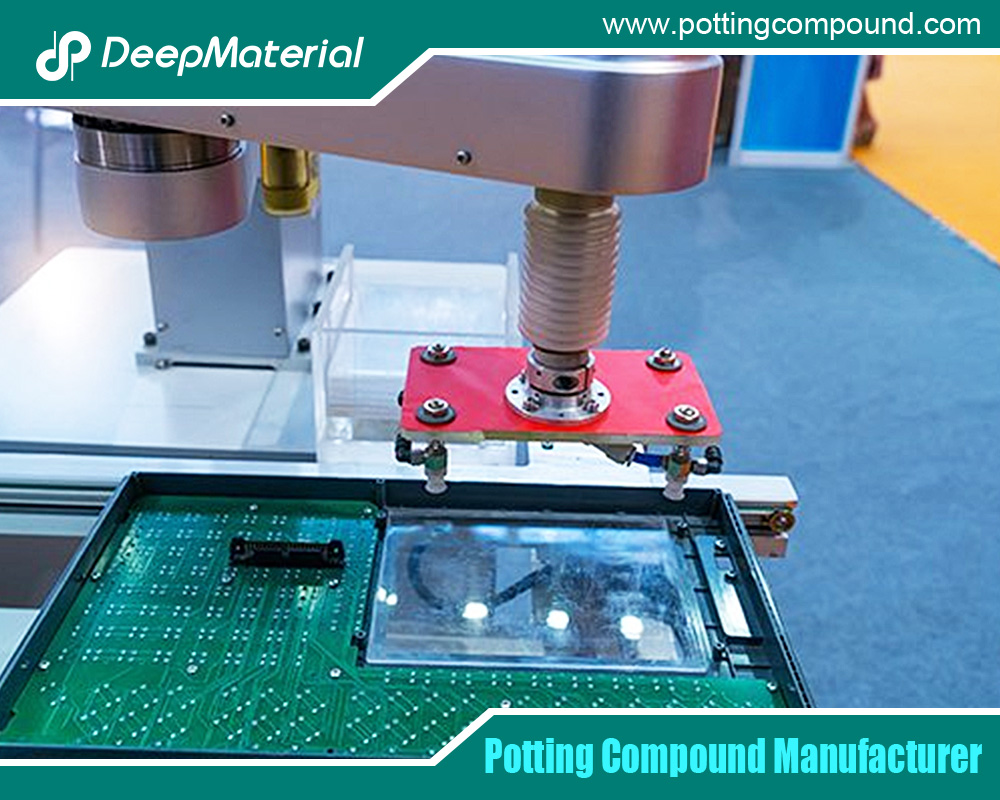

UV-curable potting compounds represent a high-efficiency option for LED encapsulation, particularly in shallow applications. Based on acrylic, epoxy, or silicone oligomers with photoinitiators, they polymerize rapidly under UV light (320-400 nm).Properties: Fast curing in seconds to minutes, enabling high-throughput. Crystal-clear transparency for optical clarity in LED lenses. Good adhesion and environmental resistance, though depth-limited to 5-10 mm due to light penetration.

Advantages: High efficiency reduces cycle times and energy use—no heat required. No waste from mixing, as single-component. Excellent for shallow potting, offering UV resistance and minimal shrinkage.

Disadvantages: Unsuitable for deep or opaque assemblies; requires UV equipment. Potential incomplete cure in shadows. Higher initial costs for setups.

Applications: Shallow LED potting in displays and indicators, where speed is key.

Comparative Analysis

| Type | Properties | Advantages | Disadvantages | Applications in LEDs |

| Silicone | Soft, elastic, -100°C to 200°C, water/UV resistant | Detachable, low stress, wide temp range | Expensive, lower strength | Outdoor signage, automotive |

| Epoxy | Hard, rigid, high strength, chemical resistant | Strong adhesion, cost-effective | Non-detachable, brittle at low temp | Displays, power modules |

| Polyurethane | Elastic, flexible, good moisture resistance | Balanced properties, fast cure | Difficult to detach, moisture-sensitive storage | Wearables, taillights |

| UV-Curable | Fast-cure, clear, efficient for shallow | High throughput, no heat | Depth-limited, equipment needed | Indicators, shallow assemblies |

Silicones lead in extremes, epoxies in rigidity, PUs in balance, UV in speed.

Case Studies and Future Trends

In a automotive LED case, silicone potting extended lifespan by 50% in humid conditions. Epoxy use in displays improved thermal management. PU in flex LEDs enhanced durability. UV-curable sped up production for consumer goods.

Future: Eco-friendly, bio-based compounds; smart materials with self-healing.

Conclusion

LED potting glues—silicone, epoxy, polyurethane, and UV-curable—offer tailored solutions for protection and performance. Selecting the right type optimizes LED reliability, paving the way for innovative lighting advancements.

For more about in-depth analysis of several common LED potting glue types, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?

- Usage Methods of LED Potting Compounds: From Mixing to Curing – A Complete Step-by-Step Guide