A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

- Electronic Potting Material Manufacturer

- May 21, 2025

- circuit board potting, conformal coating material, conformal coating silicone, conformal coating waterproof, electrical potting compound, electronic epoxy encapsulant potting compounds, encapsulation materials, Encapsulation Materials Factory, Encapsulation Materials Manufacturer, Encapsulation Materials Supplier, epoxy encapsulation, epoxy encapsulation electronic components, epoxy encapsulation for photovolatics, epoxy encapsulation led, epoxy encapsulation meaning, epoxy encapsulation molding compound, epoxy potting compound, epoxy resin encapsulation, epoxy resin encapsulation solar panels, pcb encapsulation epoxy, polyurethane potting compound, polyurethane potting compound for electronics, potting compound for electronics, potting compound for pcb, potting compound vs epoxy, potting material for electronic components, potting material for electronics, potting pcb, silicone potting compound for electronics, UV curing potting compound, waterproof potting compound

A Comprehensive Guide to Evaluating the Reliability of Encapsulation Materials for Encapsulated PCBs

In modern electronic devices, the printed circuit board (PCB) plays a central role, and the encapsulation technology is a key means to ensure the long-term stable operation of the PCB in complex environments. Encapsulated PCBs can effectively resist the adverse effects of moisture, dust, chemical substances, temperature changes, and other unfavorable factors, thus extending their service life. However, the reliability of the encapsulation material is directly related to the overall performance and stability of the PCB. Therefore, how to accurately evaluate the reliability of the encapsulation material during long-term use has become an important issue to be solved urgently in the electronics industry.

The Key Role of Encapsulation Materials

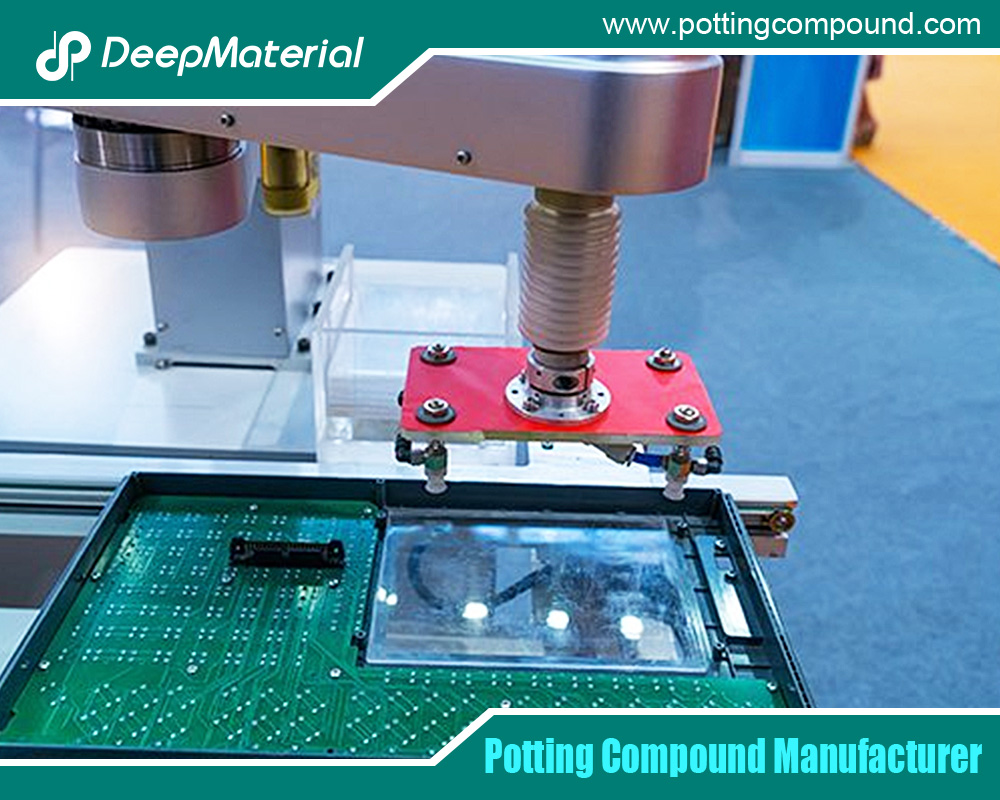

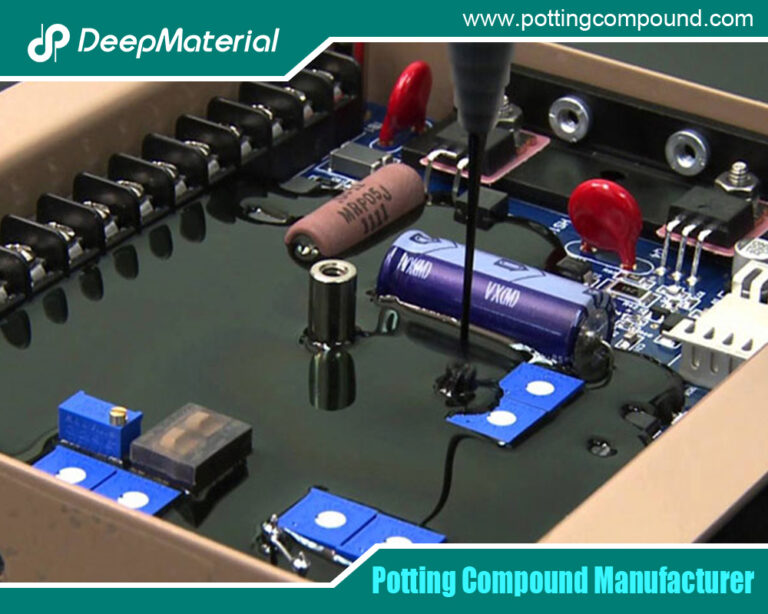

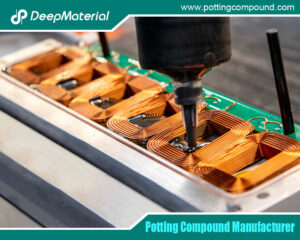

Encapsulation refers to the process of coating or injecting protective materials onto the PCB to form a solid protective layer. This process not only provides physical protection for electronic components, preventing mechanical damage, but also significantly improves the thermal stability of the PCB. By effectively dissipating heat, encapsulation helps prevent overheating, thereby extending the service life of the circuit board. In addition, encapsulation can also provide excellent electrical insulation performance, preventing short circuits and electrical failures.

Common encapsulation materials include silicone rubber, epoxy resin, and polyurethane, each with its unique performance advantages. Silicone rubber has excellent flexibility and a wide temperature range of application, making it suitable for use in environments with large temperature variations; Epoxy resin is highly favored for its high strength and excellent chemical resistance; Polyurethane provides a robust and durable solution, especially suitable for occasions that require additional impact resistance protection.

Test Methods for Evaluating the Reliability of Encapsulation Materials

Environmental Simulation Tests

- Temperature Cycle Test: Simulate the temperature changes that the PCB may encounter during actual use. The sample is repeatedly cycled between high and low temperatures. For example, it is cycled multiple times between -40°C and 125°C, and each cycle includes stages such as heating, holding, and cooling. By observing the physical changes of the encapsulation material during the temperature cycle, such as the occurrence of cracks, deformation, or delamination, evaluate its tolerance to temperature changes. Severe temperature changes will cause different degrees of thermal expansion and contraction of the encapsulation material and PCB components. If the coefficient of thermal expansion of the encapsulation material does not match that of the PCB, stress concentration is likely to occur at the interface, leading to the failure of the encapsulation material.

- Wet Heat Cycle Test: Place the sample in a high-temperature and high-humidity environment, such as at 85°C and 85% relative humidity (RH), and conduct multiple cycles of testing. In a wet heat environment, moisture will gradually penetrate into the encapsulation material, which may lead to problems such as corrosion of electronic components and a decrease in electrical performance. By regularly detecting the electrical performance, weight change, and the interface condition between the encapsulation material and the PCB of the sample, evaluate the moisture resistance of the encapsulation material and its protective ability for electronic components. For example, measure parameters such as the insulation resistance and capacitance value of the sample and observe whether they fluctuate within an acceptable range.

Mechanical Property Tests

- Vibration Test: Use a vibration table to conduct vibration tests with different frequencies and amplitudes on the encapsulated PCB to simulate the mechanical vibrations it may encounter during transportation or use. During the vibration process, the encapsulation material needs to withstand periodic stress, which may cause fatigue damage. By monitoring whether the encapsulation material cracks, falls off, and whether the solder joints of electronic components are loose, evaluate the reliability of the encapsulation material in a vibration environment. For example, use sinusoidal vibration or random vibration methods to conduct vibration tests for a certain period of time according to relevant standards, and then conduct visual inspection and electrical performance testing on the sample.

- Impact Test: Apply an instantaneous impact force to the sample, such as simulating drop and collision situations through free fall or an impact tester. The impact test can examine the cushioning ability of the encapsulation material when it is subjected to sudden mechanical impact and its protective effect on electronic components. Observe whether the encapsulation material can effectively disperse the impact force to avoid damage to electronic components, and at the same time, check whether the encapsulation material itself cracks, delaminates, and other phenomena occur.

Electrical Performance Tests

- Insulation Resistance Test: Under different environmental conditions, such as high temperature, high humidity, or after a temperature cycle, use an insulation resistance tester to measure the insulation resistance of the encapsulation material. A decrease in insulation resistance may indicate that moisture intrusion, cracks, or other defects have occurred inside the encapsulation material, resulting in a decrease in electrical insulation performance. By regularly monitoring the change trend of insulation resistance, evaluate the electrical reliability of the encapsulation material during long-term use.

- Dielectric Strength Test: Apply a gradually increasing voltage to the encapsulated PCB until the encapsulation material breaks down, and measure the breakdown voltage value. The dielectric strength reflects the tolerance of the encapsulation material to high voltages and is an important indicator for evaluating its electrical performance. During the test, observe whether there are phenomena such as discharge and flashover to determine whether the encapsulation material can meet the electrical safety requirements in actual applications.

Failure Analysis Methods

When the encapsulation material fails during the test or actual use, failure analysis is required to determine the cause of failure, providing a basis for improving the encapsulation material and process.

- Visual Inspection: Observe the surface condition of the encapsulation material with the naked eye or a microscope, such as whether there are obvious defects such as cracks, bubbles, discoloration, or delamination. Visual inspection is the first step in failure analysis, which can quickly find some intuitive problems and provide clues for subsequent analysis.

- X-ray Analysis: Use X-rays to penetrate the encapsulation material and the PCB to detect the integrity of the internal structure, such as whether the solder joints are poorly soldered, whether the electronic components are displaced, and whether there are voids inside the encapsulation material. X-ray analysis can obtain information about the internal structure without damaging the sample, which is very effective for detecting some hidden defects.

- Scanning Electron Microscopy (SEM) and Energy Dispersive Spectroscopy (EDS): Use SEM to observe the microstructure of the encapsulation material, such as the crack propagation path and the bonding condition of the interface; combined with EDS analysis, the elemental composition of the material surface can be determined to judge whether there are problems such as impurities and corrosion. The combination of SEM and EDS can deeply analyze the microscopic mechanism of the failure of the encapsulation material.

- Thermal Analysis: Use techniques such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to study the physical and chemical changes of the encapsulation material during the heating process, such as glass transition temperature, thermal decomposition temperature, and coefficient of thermal expansion. These parameters are of great significance for evaluating the thermal stability and reliability of the encapsulation material.

Long-term Monitoring and Data Accumulation

In order to more accurately evaluate the reliability of the encapsulation material, it is crucial to establish a long-term monitoring mechanism. In actual product applications, select a certain number of samples for long-term tracking, regularly detect their performance parameters, and record the usage environment conditions. Through the accumulation and analysis of a large amount of data, a mathematical model of the reliability of the encapsulation material can be established to predict its life and performance change trends under different usage conditions. At the same time, compare the monitoring data with the laboratory test results, continuously improve the evaluation method and standards, and improve the accuracy of the evaluation of the reliability of the encapsulation material.

Evaluating the reliability of the encapsulation material of encapsulated PCBs during long-term use requires the comprehensive application of a variety of test methods and failure analysis techniques, and a comprehensive evaluation from multiple perspectives such as environmental adaptability, mechanical properties, and electrical performance. Through long-term monitoring and data accumulation, continuously optimize the evaluation system to provide strong support for the reliable design and production of electronic devices, ensuring that electronic devices can operate stably for a long time in complex usage environments.

For more about a comprehensive guide to evaluating the reliability of encapsulation materials for encapsulated PCBs, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Conformal Coating vs. Potting: What’s the Difference for Your PCB?

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

Tags

Related Posts

Common Mistakes to Avoid When Applying Conformal Coating

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB