Which Glues Are Suitable for Encapsulation of Electronic Products?

- Electronic Potting Material Manufacturer

- December 2, 2025

- Ceramic Potting Compound Manufacturer, circuit board encapsulation, conformal coating for electronics, conformal coating for pcb, conformal coating material, conformal coating silicone, conformal coating spray, Electrical Component Encapsulation, electrical encapsulation, electrical potting compound, electronic board level underfill and encapsulation material market, electronic encapsulation, electronic encapsulation china hotsale, electronic encapsulation china wholesale, Electronic Encapsulation in Potting Material Manufacturing, electronic encapsulation manufacturer, Electronic Encapsulation Manufacturing, Electronic Encapsulation Methods, Electronic encapsulation process, electronic encapsulation supplier, Encapsulation, encapsulation electronic, Encapsulation Glues, epoxy encapsulation, epoxy encapsulation electronic components, epoxy encapsulation for photovolatics, epoxy encapsulation led, epoxy encapsulation meaning, epoxy encapsulation molding compound, epoxy resin encapsulation, epoxy resin encapsulation solar panels, potting compound for electronics, potting compound for pcb, UV curing potting compound, UV encapsulation adhesive, uv encapsulation epoxy, UV encapsulation glue

Which Glues Are Suitable for Encapsulation of Electronic Products?

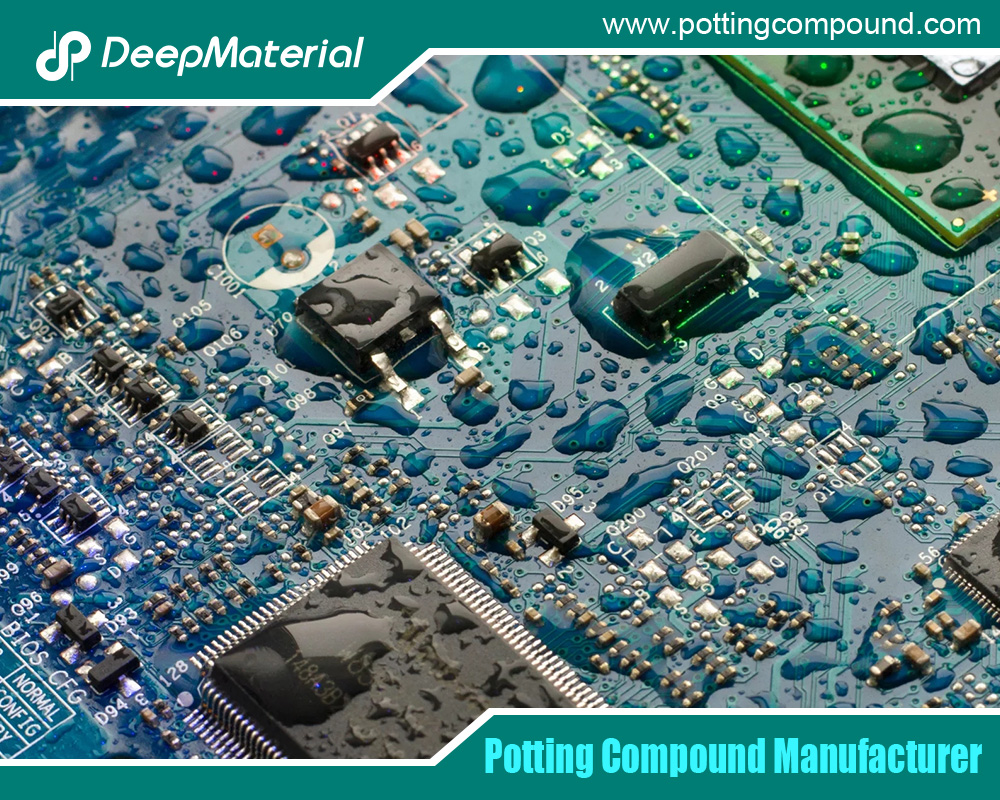

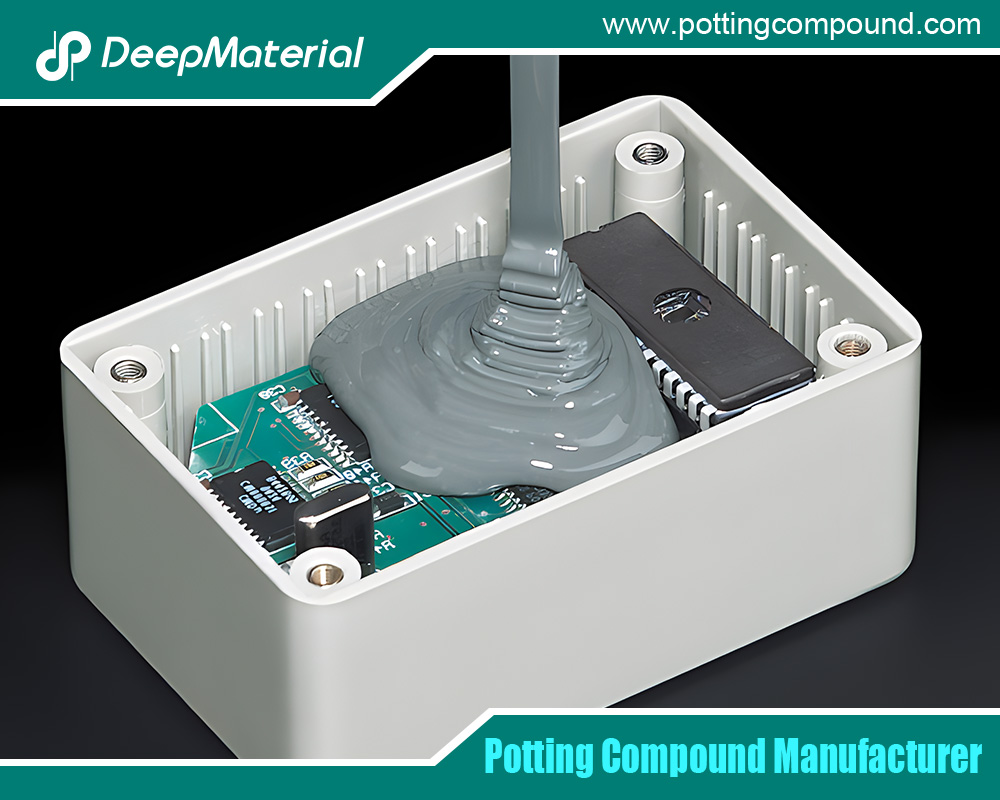

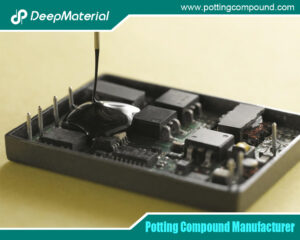

In the rapidly evolving world of electronics, protecting sensitive components from environmental hazards is crucial for ensuring reliability and longevity. Encapsulation, also known as potting, involves sealing electronic assemblies with a protective material to shield them from moisture, dust, chemicals, vibrations, and thermal stresses. This process is widely used in industries such as automotive, aerospace, consumer electronics, and telecommunications. The choice of glue or adhesive for encapsulation plays a pivotal role, as it must provide not only mechanical protection but also electrical insulation and thermal management.

Glues suitable for electronic encapsulation are typically thermosetting polymers that cure to form a solid barrier. Common types include epoxy resins, silicones, and polyurethanes, each offering unique properties tailored to specific applications. These materials must adhere well to substrates like circuit boards, wires, and housings while maintaining performance under extreme conditions. For instance, in high-reliability applications like medical devices or military equipment, the encapsulant must withstand temperatures from -50°C to over 150°C without degrading.

The importance of encapsulation cannot be overstated. Without proper protection, electronic products are susceptible to failures caused by corrosion, short circuits, or mechanical damage. According to industry standards, encapsulated electronics can extend product life by up to 50% in harsh environments. This article explores the most suitable glues for encapsulation, their properties, advantages, disadvantages, and selection criteria, providing a comprehensive guide for engineers and manufacturers.

Types of Glues for Electronic Encapsulation

- Epoxy Resins

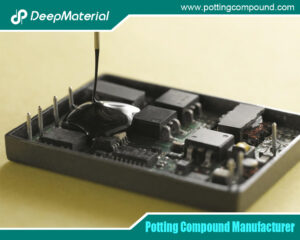

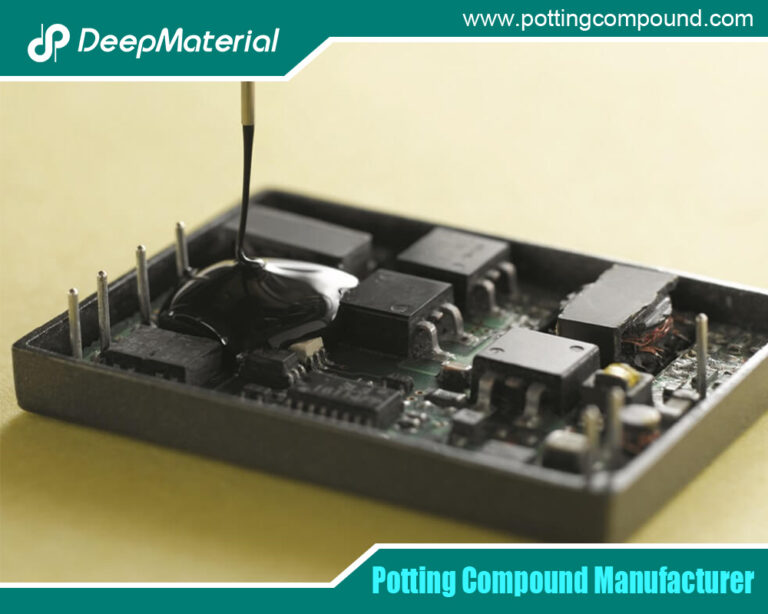

Epoxy resins are among the most popular choices for encapsulating electronic products due to their exceptional strength and durability. These two-part systems consist of a resin and a hardener that react to form a rigid, cross-linked polymer. Epoxies are ideal for potting printed circuit boards (PCBs), transformers, and sensors, where high mechanical protection is required.

Key properties of epoxy resins include excellent adhesion to metals, plastics, and ceramics, high chemical resistance, and superior electrical insulation with dielectric strengths often exceeding 15 kV/mm. They can operate in temperatures ranging from -55°C to 200°C, making them suitable for demanding applications like automotive engine control modules. For example, cycloaliphatic epoxies are formulated for high electrical resistance and heat tolerance, ensuring minimal degradation over time.

Advantages of epoxies include their low shrinkage during cure (typically less than 1%), which reduces stress on delicate components, and their ability to provide a hermetic seal against moisture and gases. They also offer good thermal conductivity, often around 0.5-1 W/m·K, helping dissipate heat from power electronics. In terms of cost, epoxies are relatively affordable and available in various viscosities for easy dispensing.

However, epoxies have drawbacks. Their rigidity can lead to brittleness, making them less suitable for applications with high vibration or thermal cycling, as cracks may develop. Curing times can be long, sometimes requiring heat acceleration, and once cured, they are difficult to remove for repairs, which poses challenges in rework scenarios. Additionally, some formulations release exothermic heat during curing, potentially damaging heat-sensitive components if not managed properly.

Applications abound in the electronics sector. For instance, in underwater electronics like sonar systems, specialized epoxies provide pressure resistance and waterproofing. Commercial products like MG Chemicals’ epoxy potting compounds are UL-rated for flame retardancy, enhancing safety in consumer devices.

- Silicone Adhesives

Silicone-based glues offer a flexible alternative for electronic encapsulation, excelling in environments with extreme temperature fluctuations and mechanical stress. These one- or two-part systems cure via moisture or heat to form a rubbery elastomer, providing excellent vibration damping and thermal stability.

Silicones can withstand temperatures from -65°C to 300°C, far surpassing many other materials, and maintain flexibility even at low temperatures. They exhibit low dielectric constants (around 2.5-3.5), making them ideal for high-frequency applications like RF modules. Their hydrophobicity repels water, offering superior moisture protection without the need for additional coatings.

The primary advantages of silicones include their softness, which absorbs shocks and reduces stress on components, and their repairability—cured silicones can often be cut away without damaging the underlying electronics. They cure with minimal shrinkage and no byproducts, ensuring clean processing. Silicones also provide excellent UV and ozone resistance, prolonging service life in outdoor applications.

On the downside, silicones have lower mechanical strength compared to epoxies, with tensile strengths typically below 5 MPa, which may not suffice for high-load scenarios. They are more expensive and can outgas volatile compounds during cure, potentially contaminating sensitive optics or contacts. Adhesion to certain substrates may require primers, adding complexity to the process.

In practice, silicones are used for encapsulating LEDs, power supplies, and automotive sensors. Products like Momentive’s silicone gels provide thermal stability and stress relief for delicate assemblies. In smartphones and wearables, they protect against dust and sweat while allowing for flexibility in flexible circuits.

- Polyurethane Potting Compounds

Polyurethanes strike a balance between the rigidity of epoxies and the flexibility of silicones, making them versatile for electronic encapsulation. These two-part systems cure to form a tough yet elastic material, suitable for potting connectors, cables, and control modules.

Polyurethanes offer good chemical resistance and operate effectively up to 125°C, with some formulations extending to 150°C. They provide electrical insulation with dielectric strengths of 10-20 kV/mm and can be formulated for low viscosity to flow into intricate spaces.

Advantages include excellent impact resistance and flexibility, which protect against vibrations in transportation electronics. They cure quickly at room temperature, reducing production time, and are often more cost-effective than silicones. Polyurethanes also exhibit low water absorption, enhancing humidity protection.

Disadvantages involve sensitivity to moisture during mixing, which can cause foaming and voids if not handled carefully. They have lower heat resistance than epoxies or silicones, limiting use in high-temperature environments, and may yellow over time under UV exposure.

Common applications include encapsulating EV battery modules and industrial sensors. Epic Resins’ polyurethane compounds are designed for electronic control modules, offering durability in harsh conditions.

- Other Glues and Emerging Options

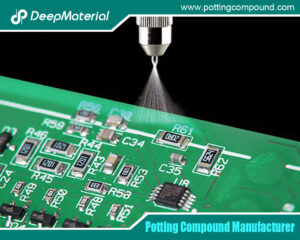

While epoxies, silicones, and polyurethanes dominate, other glues like acrylics and hot-melt adhesives find niche uses. Acrylics provide fast UV curing for low-volume production but lack the robustness for severe environments.

Emerging options include hybrid systems combining epoxy and silicone properties for enhanced performance.

Advantages and Disadvantages of Encapsulation Glues

Each glue type has trade-offs. Epoxies excel in strength but are brittle; silicones offer flexibility but at higher cost; polyurethanes provide balance but with moisture sensitivity. Overall advantages include environmental protection, electrical insulation, and mechanical reinforcement. Disadvantages may involve cure times, rework difficulty, and material costs.

Selection Criteria for Encapsulation Electronic Glues

Selecting the right glue involves evaluating several factors. First, consider operating temperature: silicones for extremes, epoxies for high heat. Chemical exposure requires resistant materials like epoxies. Flexibility is key for vibration-prone applications, favoring silicones or polyurethanes.

Cure method and time affect production: room-temperature cures for polyurethanes versus heat-accelerated epoxies. Viscosity ensures proper flow; low-viscosity options for intricate designs. Regulatory compliance, such as RoHS or UL ratings, is essential. Cost, shelf life, and ease of application also play roles.

Environmental impact is increasingly important; opt for low-VOC formulations. Testing, including thermal cycling and humidity exposure, validates choices.

Case Studies and Applications

In automotive electronics, polyurethane potting protects ECUs from vibrations and fluids. Aerospace uses epoxies for avionics encapsulation against altitude pressures. Consumer gadgets like wearables rely on silicones for flexibility and water resistance. Best practices include surface preparation for adhesion, vacuum degassing to eliminate voids, and controlled curing to avoid defects.

Conclusion

Choosing the right glue for encapsulating electronic products depends on balancing protection needs with material properties. Epoxies provide robust defense, silicones offer flexibility, and polyurethanes deliver versatility. By considering selection criteria and leveraging advancements, manufacturers can enhance product reliability. As electronics advance, innovative glues will continue to evolve, ensuring devices withstand tomorrow’s challenges.

For more about which glues are suitable for encapsulation of electronic products, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Core Differences Between Different Conformal Coating Types?

- The Benefits of Conformal Coating for Electronics Products

- Conformal Coating Spray

- UV Curing Potting Compound

- The Ultimate Guide to Electrical Potting Compound and Market Application

- The Top Polyurethane Potting Compound

- Advanced Epoxy Potting Compound for Superior Electronic Protection

- Waterproof Potting Compound: A Comprehensive Guide

- Silicone Potting Compound for Electronics

Tags

Related Posts

What Are the Core Differences Between Different Conformal Coating Types?

The Benefits of Conformal Coating for Electronics Products

Conformal Coating Spray

UV Curing Potting Compound