In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

- Electronic Potting Material Manufacturer

- June 18, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, china electronic potting silicone manufacturer, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating silicone, electronic potting, Electronic Potting and Encapsulation, Electronic Potting and Encapsulation Resins, electronic potting compound, Electronic Potting Compound Market, electronic potting compounds, Electronic Potting Compounds Manufacturer, electronic potting material, Electronic Potting Material Manufacturing, Electronic Potting Process, electronic potting silicone, electronic potting silicone manufacturer, uv electronic potting compound

In – depth Analysis of the Curing Characteristics of Electronic Potting Compounds

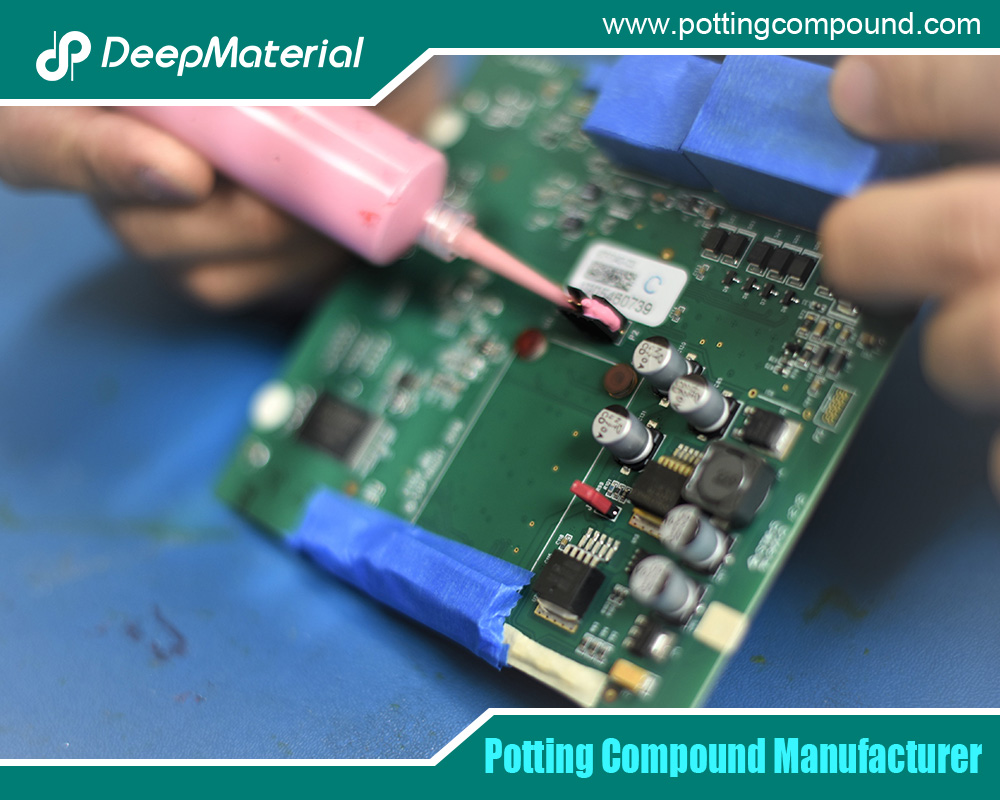

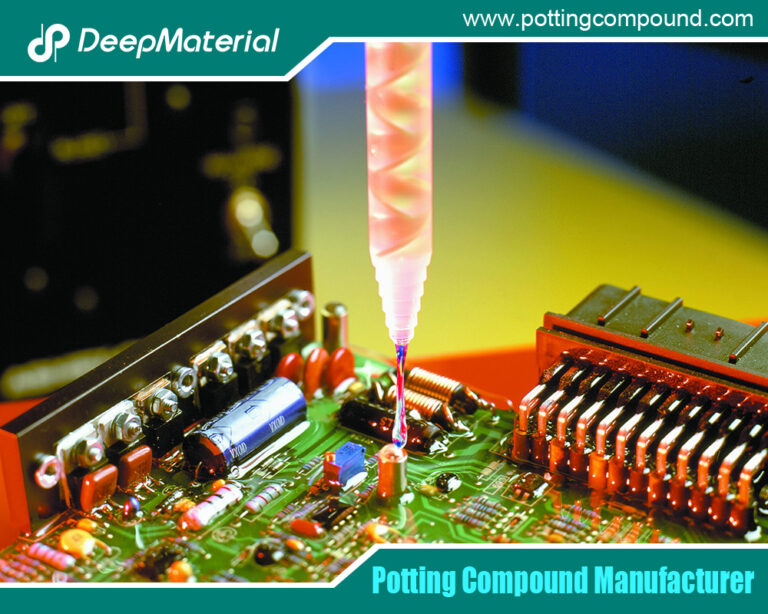

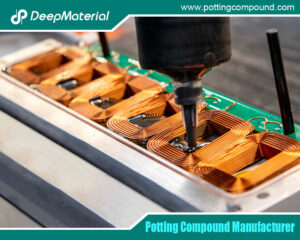

Electronic potting compounds play a vital role in the electronics industry. They can protect electronic components from environmental factors like moisture, dust, and mechanical impact. At the same time, they can also assist in heat dissipation and enhance electrical insulation performance. The curing characteristics of potting compounds, especially curing time and curing temperature, directly determine the efficiency of the potting process and the performance of the final product. Understanding and mastering these characteristics is of great significance for electronics manufacturing enterprises to optimize production processes and ensure product quality.

Basic Concepts of Curing Time and Curing Temperature

2.1 Curing Time

Curing time refers to the time required for electronic potting compounds to undergo a chemical reaction and reach the specified performance indicators from the moment of mixing and preparation. It can generally be divided into gel time and full curing time. Gel time is the time when the potting compound changes from a liquid state to a semi – solid state (similar to a gel state). At this point, the compound has lost its fluidity but has not yet fully cured. Full curing time is the time required for the compound to reach a stable state of final physical and chemical properties.

2.2 Curing Temperature

Curing temperature refers to the environmental temperature that promotes the curing reaction of the potting compound and achieves an ideal curing effect. Different types of potting compounds have different optimal curing temperature ranges. Curing within this range can obtain good curing quality and performance.

Factors Influencing Curing Time and Curing Temperature

3.1 Chemical Composition and Formula

The basic chemical composition of different types of electronic potting compounds determines the mechanism and speed of the curing reaction. For example, epoxy resin potting compounds are usually composed of epoxy resin and a curing agent. The type (such as amine – type, anhydride – type, etc.) and dosage of the curing agent will significantly affect the curing time and temperature. Amine – type curing agents have high reaction activity and a relatively fast curing speed, and they may be able to cure at lower temperatures. Anhydride – type curing agents, on the other hand, require higher temperatures and longer time to complete the curing reaction.

The curing of silicone potting compounds is usually based on addition reactions or condensation reactions. Addition – reaction – type silicone potting adhesives have a relatively fast curing speed and can cure at room temperature or lower temperatures. Condensation – reaction – type silicone potting adhesives may require certain humidity conditions and a relatively long time to complete the curing.

The curing speed and temperature of polyurethane potting compounds are affected by factors such as the ratio of isocyanate to polyol, and the type and dosage of the catalyst. A proper formula design can meet the production efficiency while ensuring the performance of the potting adhesive.

3.2 Environmental Conditions

Environmental temperature and humidity have a significant impact on the curing process of potting compounds. Generally, an increase in temperature will accelerate the curing reaction rate and shorten the curing time. However, too high a temperature may lead to uneven curing, generate internal stress, and even affect the performance of the potting adhesive. For example, when epoxy resin cures rapidly at high temperatures, bubbles may be generated due to too reaction, reducing the potting quality. Humidity has a great influence on the curing of condensation – reaction – type silicone potting adhesives. Insufficient humidity may lead to incomplete curing and affect the final performance.

In addition, the air flow in the environment will also affect the curing process. Moderate air flow is helpful to remove the small molecular substances (such as water produced by the condensation reaction) generated during the curing process. But too strong an air flow may cause the potting surface to dry too quickly, resulting in poor surface quality.

3.3 Curing Process and Equipment

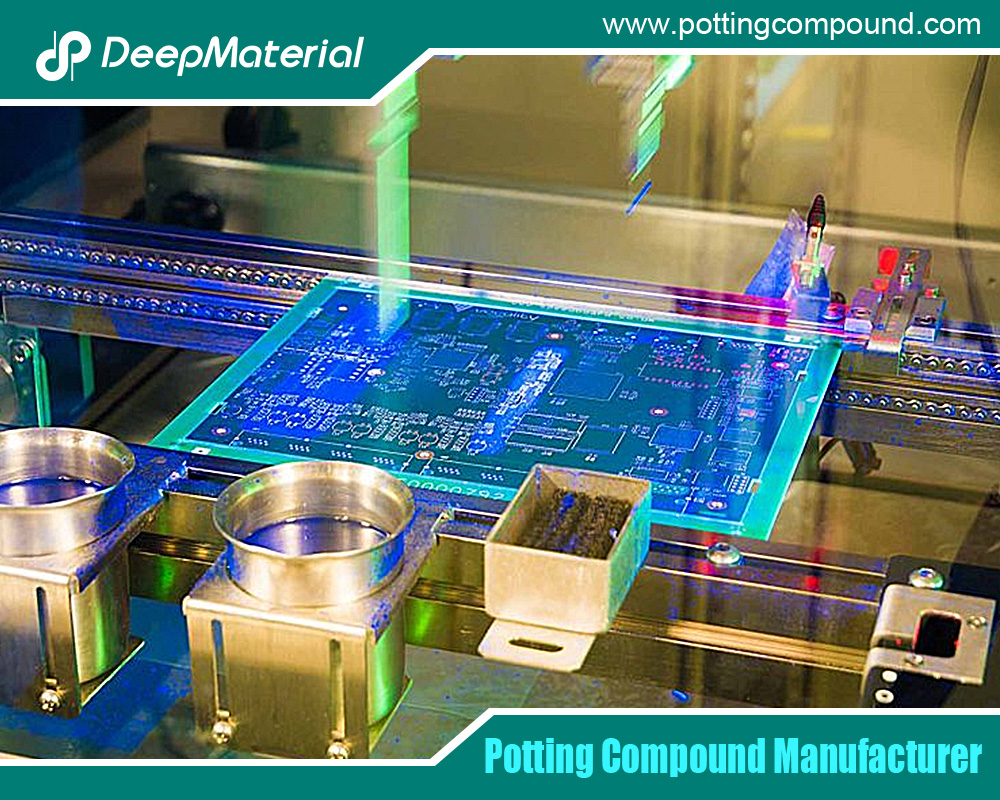

The mixing method and mixing uniformity of the potting compound will affect the consistency of the curing reaction. Mechanical stirring can improve the mixing efficiency, but if the stirring speed is too fast or the time is too long, too many bubbles may be introduced, affecting the curing quality. At the same time, the temperature control accuracy and stability of the potting equipment are also very important. Precise temperature control can ensure that the potting compound reacts at the set curing temperature and ensure the consistency of the curing effect.

Curing Characteristics of Different Types of Electronic Potting Compounds

4.1 Epoxy Resin Potting Compounds

The curing time and temperature range of epoxy resin potting compounds are relatively wide. At room temperature (about 25°C), when using fast – curing amine – type curing agents, the gel time may be between 30 minutes and several hours, and the full curing time may take 12 – 24 hours. If heat curing is used, at 60 – 80°C, the curing time can be shortened to 2 – 4 hours. At high temperatures of 120 – 150°C, the curing time can even be shortened to 30 minutes to 1 hour. However, although high – temperature curing improves production efficiency, attention needs to be paid to controlling the heating rate to avoid excessive internal stress caused by too rapid temperature change, which may lead to component cracking or the separation of the potting adhesive from the component interface.

4.2 Silicone Potting Compounds

Addition – reaction – type silicone potting adhesives can usually cure at room temperature (25°C). The gel time is generally 30 minutes to several hours, and the full curing time may take 12 – 24 hours. By heating (such as 60 – 80°C), the curing time can be greatly shortened. For example, the gel time can be shortened to 10 – 30 minutes, and the full curing time can be shortened to 2 – 4 hours. The curing speed of condensation – reaction – type silicone potting adhesives at room temperature is relatively slow. The gel time may take several hours or even longer, and the full curing time may take several days. Increasing the environmental humidity and appropriate heating (40 – 60°C) can accelerate their curing process.

4.3 Polyurethane Potting Compounds

The curing speed and temperature of polyurethane potting compounds vary with different formulas. For room – temperature curing polyurethane potting adhesives, the gel time is generally 1 – 3 hours, and the full curing time may take 12 – 24 hours. Under heating conditions (such as 50 – 70°C), the curing time can be shortened to 2 – 6 hours. Some special formula polyurethane potting adhesives can even cure rapidly at lower temperatures (such as 30 – 40°C) to meet the potting needs of temperature – sensitive electronic components.

Impact of Curing Time and Curing Temperature on Product Performance

5.1 Impact on Mechanical Properties

Incomplete curing will lead to insufficient mechanical strength of the potting compound, and the performance such as hardness, impact resistance, and tensile strength cannot meet the expectations. For example, if the curing time of epoxy resin potting adhesive is too short or the temperature is too low, the molecular chain cross – linking is insufficient, and its hardness and impact resistance will decrease significantly. It is easy to be damaged when subjected to mechanical vibration or impact. Excessive curing (such as too high temperature or too long curing time) may make the potting adhesive brittle and reduce flexibility, also affecting mechanical properties.

5.2 Impact on Electrical Properties

Poor curing will affect the electrical insulation performance of the potting compound, leading to problems such as reduced insulation resistance and unstable dielectric constant. For example, when the silicone potting adhesive is not fully cured, there may be unreacted small molecular substances inside, which may migrate under the electric field and affect the insulation performance. Appropriate curing time and temperature can ensure that the potting adhesive forms a dense molecular structure, improving the electrical insulation performance and voltage resistance.

5.3 Impact on Thermal Performance

The degree of curing directly affects the thermal conductivity and thermal expansion coefficient of the potting compound. The incompletely cured potting adhesive has a loose internal structure and low heat transfer efficiency, which is not conducive to the heat dissipation of electronic components. At the same time, the thermal expansion coefficient may be on the large side, and thermal stress is easy to generate with electronic components when the temperature changes, leading to component damage. Reasonably controlling the curing time and temperature can make the potting adhesive form a uniform and dense structure to optimize the thermal performance.

Strategies for Optimizing Curing Time and Curing Temperature

6.1 Reasonable Selection of Potting Compounds

According to the service environment, performance requirements, and production process characteristics of electronic components, select the appropriate type and formula of potting compounds. For scenarios requiring fast production, fast – curing potting adhesives can be selected. For components sensitive to temperature, low – temperature curing or room – temperature curing potting adhesives can be selected.

6.2 Precise Control of Environmental Conditions

During the potting process, strictly control the environmental temperature and humidity to maintain the stability of the environment. A constant temperature and humidity workshop or local environmental control equipment can be used to ensure that the potting compound cures in a suitable environment. At the same time, reasonably arrange the air flow in the potting area to avoid adverse effects.

6.3 Optimization of Curing Process and Equipment

Optimize the mixing process of the potting compound to ensure uniform mixing and avoid inconsistent curing caused by uneven mixing. Select potting equipment and curing equipment with high precision and good stability to accurately control the curing temperature and time. For example, use a curing furnace with a temperature feedback control system to monitor and adjust the temperature in real time to ensure the stability of the curing process.

Conclusion

Curing time and curing temperature of electronic potting compounds are key factors affecting the potting process and product performance. Having an in – depth understanding of the curing characteristics of different types of potting compounds, mastering various factors affecting the curing process, and adopting reasonable optimization strategies can effectively improve the potting quality and production efficiency and ensure the reliability and stability of electronic equipment. In the context of the continuous development of the electronics industry, the continuous research and optimization of the curing characteristics of electronic potting compounds are of great significance for promoting the progress of electronics manufacturing technology. In the future, with the continuous emergence of new electronic components and application scenarios, the research and innovation on the curing characteristics of electronic potting compounds will face new challenges and opportunities.

For more about choosing the top in – depth analysis of the curing characteristics of electronic potting compounds, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB