A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

- Electronic Potting Material Manufacturer

- June 11, 2025

- Automotive potting material manufacturers, Benefits of Potting Electronics, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, china electronic potting silicone manufacturer, circuit board potting, circuit board potting compound, Connector Potting Compound, electronic epoxy encapsulant potting compounds, encapsulating materials, encapsulating materials factory, encapsulating materials manufacturer, encapsulating materials supplier, epoxy encapsulation, epoxy encapsulation electronic components, epoxy encapsulation for photovolatics, epoxy encapsulation led, epoxy encapsulation meaning, epoxy encapsulation molding compound, epoxy resin encapsulation, epoxy resin encapsulation solar panels, pcb encapsulation epoxy, polyurethane potting compound, polyurethane potting compound for electronics, potting compound for electronics, potting compound for pcb, potting material for electronic components, potting material for electronics, silicone potting compound for electronics, waterproof potting compound

A Comprehensive Analysis of the Environmental Performance of Encapsulating Materials: From Regulations to Practices

In modern industrial manufacturing, encapsulating materials are widely used in numerous fields such as electronics, automobiles, aerospace, etc., playing a crucial role in insulation, sealing, protection, and other aspects. With the continuous enhancement of global environmental awareness, the attention paid to whether encapsulating materials meet environmental protection requirements has also increased day by day. Environmentally friendly encapsulating materials are not only related to the protection of the ecological environment but also closely connected with human health, sustainable development, and corporate social responsibility. Therefore, it is particularly important to conduct an in-depth discussion on the environmental performance of encapsulating materials.

Overview of Encapsulating Materials

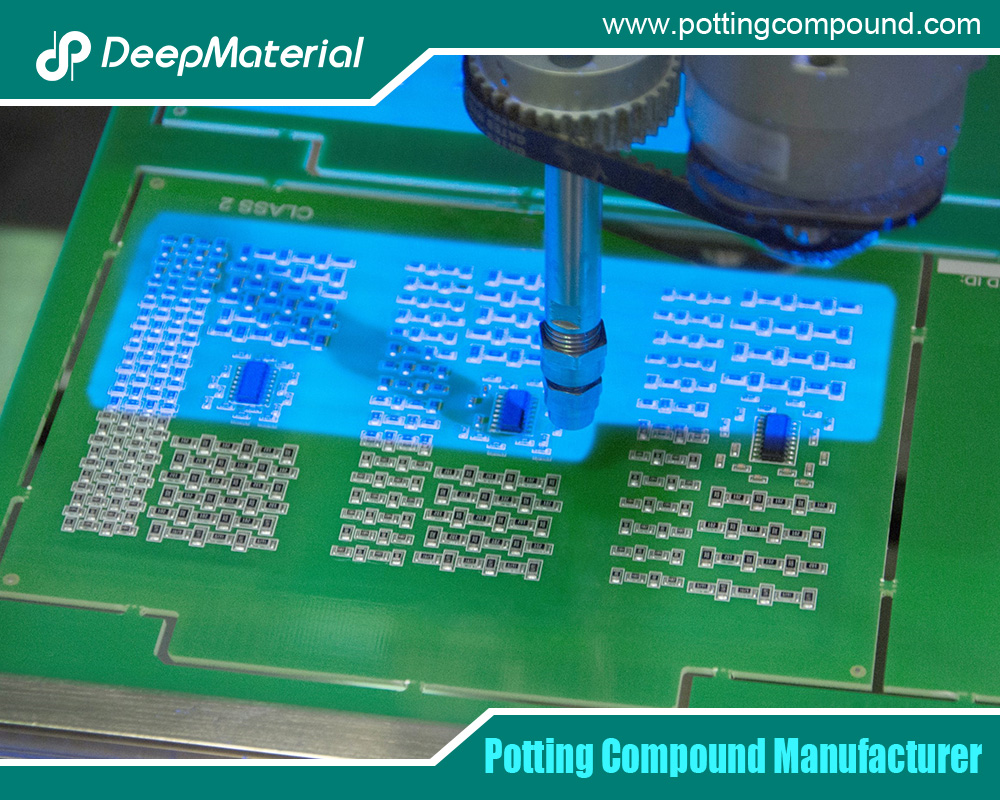

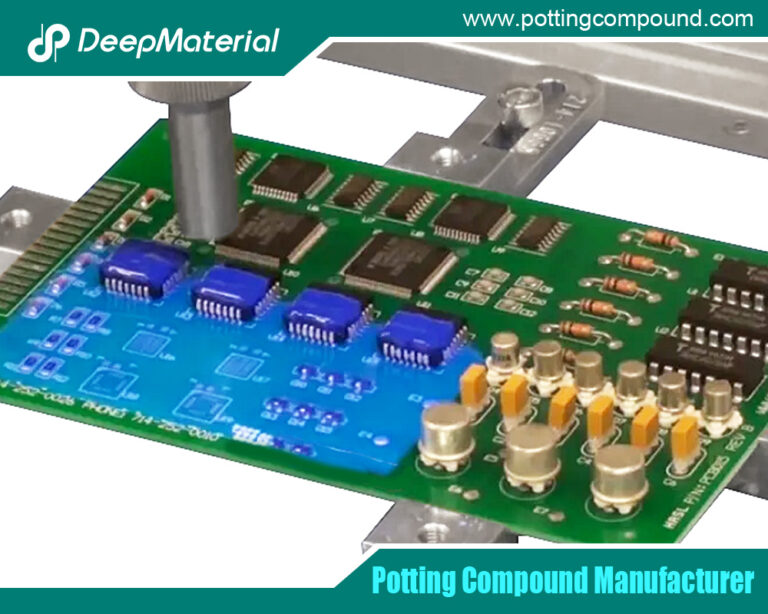

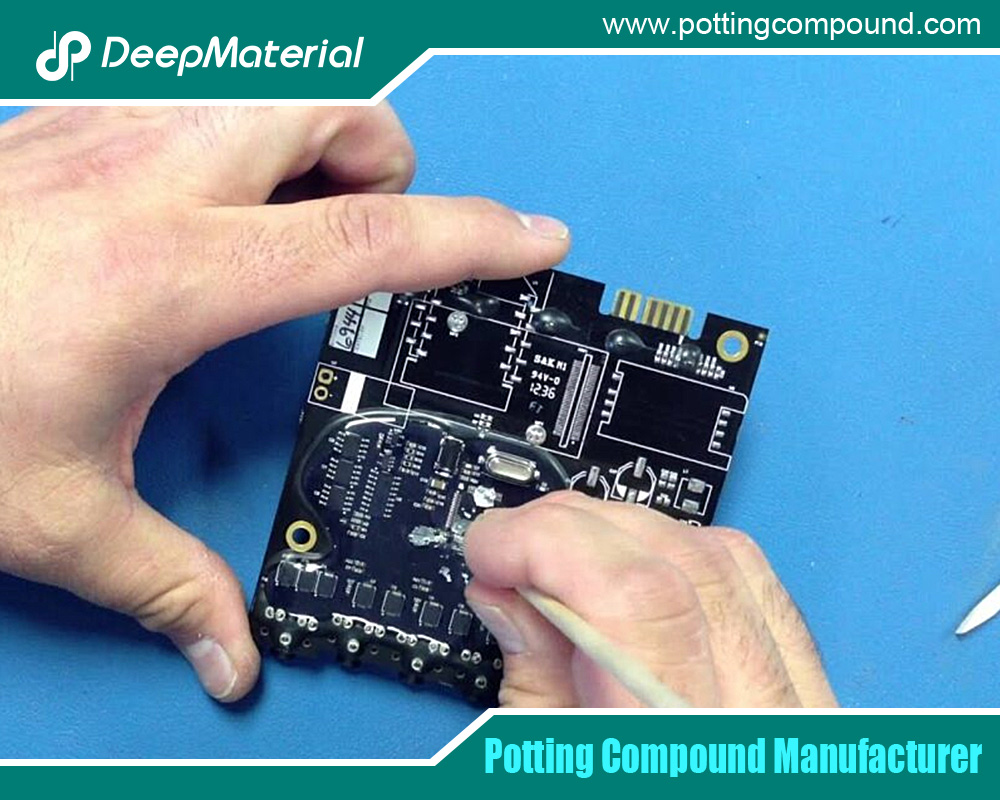

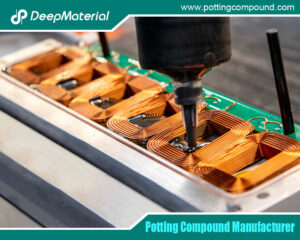

Encapsulating materials are substances used to fill and seal electronic components, mechanical parts, etc. Their function is to protect internal components from the influence of external environmental factors, such as moisture, dust, chemical substances, mechanical impacts, etc., thereby improving the reliability and service life of products. Common encapsulating materials mainly include epoxy resin encapsulating adhesives, silicone encapsulating adhesives, and polyurethane encapsulating adhesives.

Epoxy resin encapsulating adhesives have excellent bonding strength, hardness, and chemical corrosion resistance. After curing, they form a hard solid, which can provide good mechanical protection for the encapsulated objects. Their electrical insulation performance is also quite outstanding, so they are widely used in the field of electronics and electrical appliances, such as the encapsulation of transformers, circuit boards, etc. However, during the curing process of epoxy resin encapsulating adhesives, some volatile organic compounds (VOCs) may be released, which pose a certain potential hazard to the environment and human health.

Silicone encapsulating adhesives are highly favored for their excellent high-temperature and low-temperature resistance, as well as good flexibility and electrical insulation properties. They are liquid before vulcanization, making them easy to pour, and during the vulcanization process, no low molecular substances are generated, and there is no stress shrinkage. They can be deeply vulcanized, and have little corrosion to the encapsulated components in the adhesive layer. Transparent silicone encapsulating adhesives become transparent elastomers after vulcanization, which is convenient for the detection and repair of internal components. Silicone encapsulating adhesives are often used for the encapsulation of electronic and electrical components, such as LED driving power supplies, automotive electronic sensors, etc., to play the roles of moisture-proof, dust-proof, anti-corrosion, and shock-proof. However, the production raw materials of some silicone encapsulating adhesives may have the problem of resource scarcity or have a certain impact on the environment.

Polyurethane encapsulating adhesives have good bonding performance, insulation performance, and weather resistance, and their hardness can be adjusted according to requirements. They overcome some disadvantages of epoxy resins, such as brittleness, and silicone resins, such as low strength and poor adhesion. They have excellent water resistance, heat resistance, cold resistance, UV resistance, acid and alkali resistance, high and low-temperature impact resistance, moisture resistance, etc., and are ideal encapsulating and protective materials for electronic components. They are especially suitable for the sealing of electronic circuit boards and components used in harsh environments, such as the fuzzy controllers of washing machines, the pulse igniters of gas water heaters, etc. Polyurethane encapsulating adhesives are usually synthesized by stepwise polymerization of polyols such as polyester, polyether, and polybutadiene oligomers with diisocyanates, using diols or diamines as chain extenders. Some environmentally sensitive chemical substances may be involved in the production process.

Environmental Protection Regulations and Standards

- International Environmental Protection Regulations:A series of strict environmental protection regulations have been formulated globally to regulate the use and production of encapsulating materials. For example, the EU’s RoHS (Restriction of Hazardous Substances Directive) clearly restricts the use of hazardous substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and their ethers in electrical and electronic equipment. If encapsulating materials are used for the encapsulation of electrical and electronic equipment, they must ensure compliance with the RoHS standard, otherwise, the products cannot enter the EU market. The implementation of this regulation has prompted encapsulating material manufacturers to actively research and develop and adopt environmentally friendly raw materials and eliminate formulations containing hazardous substances.

- Domestic Environmental Protection Policies:China has also formulated a series of environmental protection policies and standards related to encapsulating materials. The “Environmental Protection Law of the People’s Republic of China” serves as the basic law, putting forward environmental protection requirements for various industrial production activities, including the production of encapsulating materials, emphasizing the reduction of pollutant emissions and the protection of environmental quality. In terms of industry standards, for encapsulating materials used in products such as electronics and electrical appliances, the limits of hazardous substances and detection methods have been specified. For example, for some encapsulating adhesives used in electronic equipment, the content of volatile organic compounds (VOCs) must be lower than a specific limit to reduce the pollution to the atmospheric environment. The introduction of these policies and standards has promoted the development of the domestic encapsulating material industry in the direction of green environmental protection.

Analysis of Hazardous Substances in Encapsulating Materials

- Heavy Metals:Heavy metals such as lead, mercury, and cadmium that may be contained in encapsulating materials, once entering the environment, will accumulate in the soil and water bodies and are difficult to degrade. These heavy metals are highly toxic to organisms and, through the transfer of the food chain, may eventually pose a hazard to human health, such as causing damage to the nervous system, kidneys, and other organs. For example, lead can affect the intellectual development of children, and mercury can damage the nervous system and immune system. In the production process of encapsulating materials, if raw materials containing heavy metal impurities are used, or the production equipment and process control are not proper, it is possible for heavy metals to remain in the encapsulating materials.

- Volatile Organic Compounds (VOCs):Many encapsulating materials will release VOCs such as benzene, toluene, and xylene during the curing process. These substances are volatile, and after entering the atmosphere, they will participate in photochemical reactions, forming pollutants such as ozone and secondary aerosols, which will seriously affect air quality and cause environmental problems such as smog. At the same time, VOCs also pose a hazard to human health. They may irritate the respiratory tract and eyes, causing symptoms such as headache, nausea, and allergies. Long-term exposure may even be carcinogenic. Some traditional epoxy resin encapsulating adhesives and some polyurethane encapsulating adhesives will release more VOCs during the curing process.

- Other Hazardous Substances:In addition to heavy metals and VOCs, some encapsulating materials may also contain flame retardants such as polybrominated diphenyl ethers and some plasticizers. Although polybrominated diphenyl ethers have good flame retardant properties, they are difficult to decompose in the environment and will accumulate in organisms, interfering with the endocrine system and affecting the growth, development, and reproduction of organisms. Some plasticizers such as phthalates also have similar environmental risks and health hazards and may cause damage to the reproductive system.

Characteristics and Advantages of Environmentally Friendly Encapsulating Materials

- Use of Environmentally Friendly Raw Materials:Environmentally friendly encapsulating materials give priority to the use of renewable, biodegradable, or low-toxic and harmless substances in the selection of raw materials. For example, some new silicone encapsulating adhesives use plant-based raw materials to replace some traditional petrochemical raw materials, reducing the dependence on petroleum resources and simultaneously reducing the environmental impact of the products. In epoxy resin encapsulating adhesives, researchers have effectively reduced the generation of VOCs by improving the formula and using solvent-free or low-solvent raw materials.

- Low Pollution and Low Emission:Environmentally friendly encapsulating materials significantly reduce pollutant emissions during the production, use, and curing processes. Their production processes have been optimized to minimize the generation of wastewater, waste gas, and waste residue. During the use process, almost no harmful substances are released, and they will not cause harm to operators and the surrounding environment. For example, some water-based encapsulating materials use water as a solvent, avoiding the pollution problem caused by the volatilization of organic solvents, and also do not produce harmful gases during the curing process.

- Recyclability:Good recyclability is one of the important characteristics of environmentally friendly encapsulating materials. Some encapsulating materials can be recycled and processed through specific processes after the products are scrapped, realizing the recycling of materials, reducing resource waste, and the amount of waste sent to landfills. For example, certain thermoplastic encapsulating materials can be remelted and processed under heating conditions and used to manufacture new products or components.

Environmental Performance Testing Methods

- Chemical Analysis Methods:Various harmful substances in encapsulating materials can be accurately detected through chemical analysis means. For example, inductively coupled plasma mass spectrometry (ICP-MS) technology can be used to accurately determine the content of heavy metal elements; gas chromatography-mass spectrometry (GC-MS) can be used to analyze the composition and content of VOCs and other organic pollutants. These methods can provide detailed chemical composition information, providing a scientific basis for judging whether encapsulating materials meet environmental protection standards.

- Physical Performance Testing:Physical performance testing can also indirectly reflect the environmental performance of encapsulating materials. For example, by measuring the physical properties of encapsulating materials such as curing shrinkage rate, hardness, and tensile strength, their stability and reliability during actual use can be evaluated. If the performance of an encapsulating material is unstable after curing, it may lead to the exposure of internal components, increasing the risk of harmful substance leakage. At the same time, good physical performance also helps to improve the service life of products and reduce the generation of waste due to premature product damage.

- Biotoxicity Testing:Biotoxicity testing is an important method for evaluating the potential hazards of encapsulating materials to biological systems. The encapsulating materials or their extracts are brought into contact with specific biological models (such as cells, aquatic organisms, etc.), and the changes in the growth, development, physiological functions, etc. of the organisms are observed to judge the biotoxicity of the encapsulating materials. For example, the algal growth inhibition test can be used to evaluate the impact of encapsulating materials on the aquatic ecosystem; the cytotoxicity test can be used to detect the potential toxicity of encapsulating materials to human cells.

Application Case Analysis

- Electronics Industry:In the manufacturing of smartphones, to improve the waterproof, dustproof, and electrical insulation performance of the mainboard, encapsulating materials are used to encapsulate the electronic components on the mainboard. Traditional encapsulating materials may contain harmful substances, while some large smartphone manufacturers have begun to use environmentally friendly silicone encapsulating adhesives. This type of encapsulating adhesive not only meets the high-performance encapsulation requirements of smartphones but also complies with environmental protection regulations, reducing the environmental impact during the production process and the product’s service life. At the same time, due to the better stability and reliability of environmentally friendly encapsulating adhesives, it helps to improve the quality and service life of smartphones and reduce after-sales maintenance costs.

- Automotive Industry:The engine control unit (ECU) of a car requires encapsulating materials to protect the internal electronic components from the effects of high temperature, humidity, and vibration. An automotive parts supplier has adopted a new type of environmentally friendly polyurethane encapsulating adhesive to replace the traditional product. The new encapsulating adhesive meets the stringent working environment requirements of the ECU while reducing the use and emission of harmful substances. From the production perspective, its production process is more environmentally friendly, reducing the harm to the workshop environment and workers’ health; from the product life cycle perspective, after the car is scrapped, the recyclability of this encapsulating adhesive is better, which is conducive to the recycling of resources and reducing the pressure of waste treatment.

Future Development Trends

- Green R&D Direction:In the future, the R&D of encapsulating materials will pay more attention to the concept of green chemistry, and is committed to the development of new environmentally friendly encapsulating materials that are non-toxic, harmless, biodegradable, and renewable. Researchers will continuously explore new raw materials and synthesis processes, such as using bio-based materials, nanomaterials, etc. to develop high-performance environmentally friendly encapsulating materials. At the same time, by optimizing the formula design, further reduce the content of harmful substances in encapsulating materials and improve their environmental performance.

- Sustainable Development Strategy:Encapsulating material manufacturers will actively implement sustainable development strategies, and implement environmental protection concepts throughout the entire process from raw material procurement, production process control to product sales and after-sales service. Strengthen cooperation with upstream and downstream enterprises to jointly promote the green development of the entire industrial chain. For example, cooperate with raw material suppliers to develop environmentally friendly raw materials, and cooperate with customers to optimize product design to improve the use efficiency of encapsulating materials and reduce waste.

- Perfection of Industry Standards:With the continuous improvement of environmental protection requirements, the industry standards for encapsulating materials will continue to be improved. Future standards will more strictly limit the use of harmful substances, and at the same time, put forward clear requirements for the recyclability, biodegradability, and other environmental performance indicators of encapsulating materials. This will prompt enterprises to increase R&D investment, promote the innovation and progress of environmentally friendly encapsulating material technology, further standardize the market order, and promote the healthy and sustainable development of the entire encapsulating material industry.

The environmental performance of encapsulating materials has become a key factor in the development of the industry. From meeting environmental protection regulatory requirements to pursuing lower environmental impact and higher sustainability, environmentally friendly encapsulating materials are gradually becoming the mainstream of the market. Through continuous technological innovation, strict testing, and the promotion of industry standards, encapsulating materials will not only achieve their functions but also make a positive contribution to environmental protection and human health. Both enterprises and consumers should attach importance to the environmental performance of encapsulating materials and jointly promote the process of green manufacturing and sustainable development.

For more about choosing the Top Industrial Electronic Adhesives Suppliers, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Conformal Coating vs. Potting: What’s the Difference for Your PCB?

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

Tags

Related Posts

Common Mistakes to Avoid When Applying Conformal Coating

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB