Why Is Silicone Conformal Coating Regarded As the “Guardian Angel” of Electronic Components?

- Electronic Potting Material Manufacturer

- September 23, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, circuit board potting, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, Conformal Coating Material Manufacturer, Conformal Coating Material Supplier, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating silicone manufacturer, conformal coating silicone supplier, conformal coating spray, electrical potting compound, electronic epoxy encapsulant potting compounds, epoxy encapsulation electronic components, epoxy encapsulation led, epoxy encapsulation meaning, epoxy encapsulation molding compound, epoxy potting compound, polyurethane potting compound, polyurethane potting compound for electronics, potting and encapsulation, potting compound for electronics, potting compound for pcb, potting compound vs epoxy, potting material for electronic components, potting material for electronics, potting pcb, Silicone Conformal Coatings, Silicone Conformal Coatings Manufacturer, silicone potting compound for electronics, UV curing potting compound, waterproof potting compound

Why Is Silicone Conformal Coating Regarded As the “Guardian Angel” of Electronic Components?

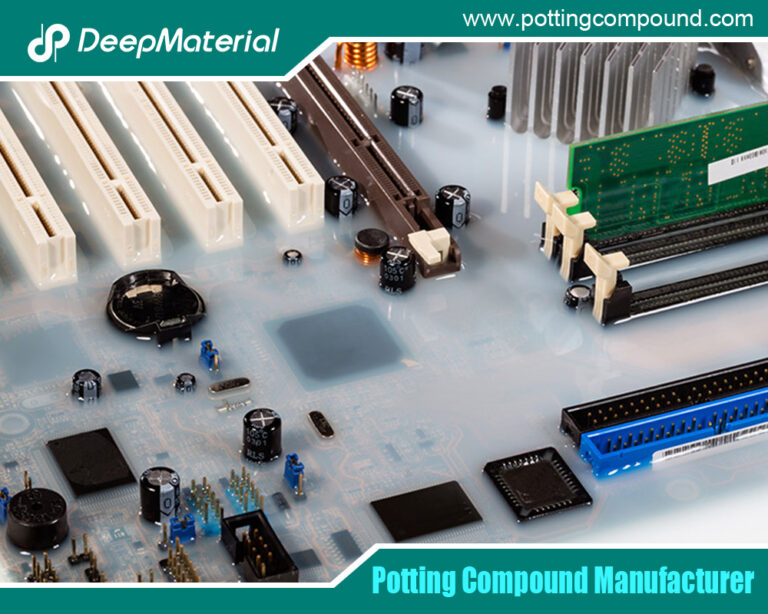

Conformal coatings are essential for protecting printed circuit boards (PCBs) from environmental stressors such as moisture, dust, chemicals, and extreme temperatures. Among the various coating materials, silicone conformal coatings stand out for their exceptional flexibility, thermal stability, and resistance to harsh conditions. Widely used in industries like aerospace, automotive, medical, and consumer electronics, silicone coatings offer unique advantages for high-reliability applications. This article explores the properties, applications, application methods, standards compliance, advantages, disadvantages, and future trends of silicone conformal coatings, providing a detailed guide for engineers and manufacturers seeking robust protection for electronic assemblies.

Understanding Silicone Conformal Coatings

Silicone conformal coatings are elastomeric, polymer-based materials applied as thin films (typically 25–250 micrometers) to PCBs. They conform to the complex geometries of electronic components, providing a flexible, protective barrier that enhances reliability. Silicone coatings are designated as “SR” (silicone resin) under the IPC-CC-830 standard, which qualifies electrical insulating compounds for PCBs. Their unique chemical structure, based on siloxane bonds, imparts properties that make them ideal for demanding environments, including extreme temperatures, high humidity, and vibration-heavy applications.

Silicone coatings are typically applied as one- or two-part systems, curing through moisture, heat, or UV exposure. Their versatility and performance make them a preferred choice for applications where other coatings, such as acrylics or polyurethanes, may fall short.

Properties of Silicone Conformal Coatings

Silicone conformal coatings are distinguished by their unique physical and chemical properties, which contribute to their effectiveness in protecting PCBs:

- Wide Temperature Range: Silicone coatings operate reliably from -55°C to 200°C, with some formulations extending beyond 250°C. This makes them suitable for high-temperature environments where other coatings degrade.

- Flexibility and Elasticity: Their elastomeric nature allows them to absorb vibrations and accommodate thermal expansion, reducing stress on components.

- Moisture Resistance: Silicone provides an excellent barrier against humidity and water ingress, preventing corrosion and electrical failures.

- UV Stability: Unlike acrylics, silicone coatings resist degradation from ultraviolet (UV) light, making them ideal for outdoor applications.

- Dielectric Strength: They offer strong electrical insulation, typically 1,000–2,000 V/mil, maintaining performance in humid conditions.

- Chemical Resistance: Silicone coatings resist mild chemicals, though they are less robust than polyurethanes or epoxies against aggressive solvents.

- Low Modulus: Their soft, rubbery texture minimizes mechanical stress on delicate components.

These properties position silicone coatings as a versatile solution for challenging environments, balancing flexibility, thermal stability, and environmental protection.

Applications of Silicone Conformal Coatings

Silicone conformal coatings are used across a wide range of industries due to their robust performance. Key applications include:

- Aerospace Electronics: Silicone coatings protect avionics and satellite systems exposed to extreme temperatures, high altitudes, and vibration. Their compliance with MIL-I-46058C ensures reliability in mission-critical systems.

- Automotive Electronics: Used in engine control units (ECUs), sensors, and infotainment systems, silicone coatings withstand heat, vibration, and thermal cycling in harsh automotive environments.

- Medical Devices: Their flexibility and biocompatibility make them suitable for medical electronics, such as diagnostic equipment and wearable devices, where reliability and safety are paramount.

- LED Lighting: Silicone coatings protect outdoor LED assemblies from UV exposure, moisture, and temperature fluctuations, ensuring long-term performance.

- Industrial Electronics: In industrial control systems and sensors, silicone coatings provide protection against dust, humidity, and moderate chemical exposure.

- Consumer Electronics: Used in ruggedized devices like outdoor cameras or wearables, where flexibility and environmental resistance are critical.

The ability of silicone coatings to perform in dynamic and extreme conditions makes them a go-to choice for high-reliability applications.

Advantages of Silicone Conformal Coatings

Silicone conformal coatings offer several advantages that make them a preferred choice for specific applications:

- Superior Thermal Stability: Their ability to operate in temperatures up to 200°C or higher surpasses most other coating materials, making them ideal for high-heat environments.

- High Flexibility: The elastomeric nature of silicone minimizes stress on components during thermal cycling or vibration, reducing the risk of cracking or delamination.

- Excellent UV Resistance: Unlike acrylics, silicone coatings maintain integrity under prolonged UV exposure, ensuring long-term reliability in outdoor applications.

- Moisture and Corrosion Protection: They provide a robust barrier against humidity and water, preventing corrosion of PCB traces and components.

- Long Service Life: Silicone coatings maintain their properties over extended periods, contributing to the durability of electronic assemblies.

- Versatile Curing Options: Available in moisture-cure, heat-cure, and UV-cure formulations, silicone coatings offer flexibility in manufacturing processes.

Disadvantages of Silicone Conformal Coatings

Despite their advantages, silicone conformal coatings have limitations that must be considered:

- Higher Cost: Silicone coatings are more expensive than acrylics or polyurethanes, increasing production costs.

- Rework Challenges: Their strong adhesion and chemical resistance make removal difficult, requiring specialized solvents or mechanical methods, which can complicate repairs.

- Tacky Surface: Silicone coatings often have a slightly tacky finish, which can attract dust or debris, potentially affecting aesthetics or performance in cleanroom environments.

- Limited Chemical Resistance: While resistant to mild chemicals, silicones are less effective against aggressive solvents or fuels compared to polyurethanes or epoxies.

- Application Complexity: Some silicone formulations require precise control of curing conditions, adding complexity to the manufacturing process.

These drawbacks necessitate careful evaluation of application requirements and cost constraints.

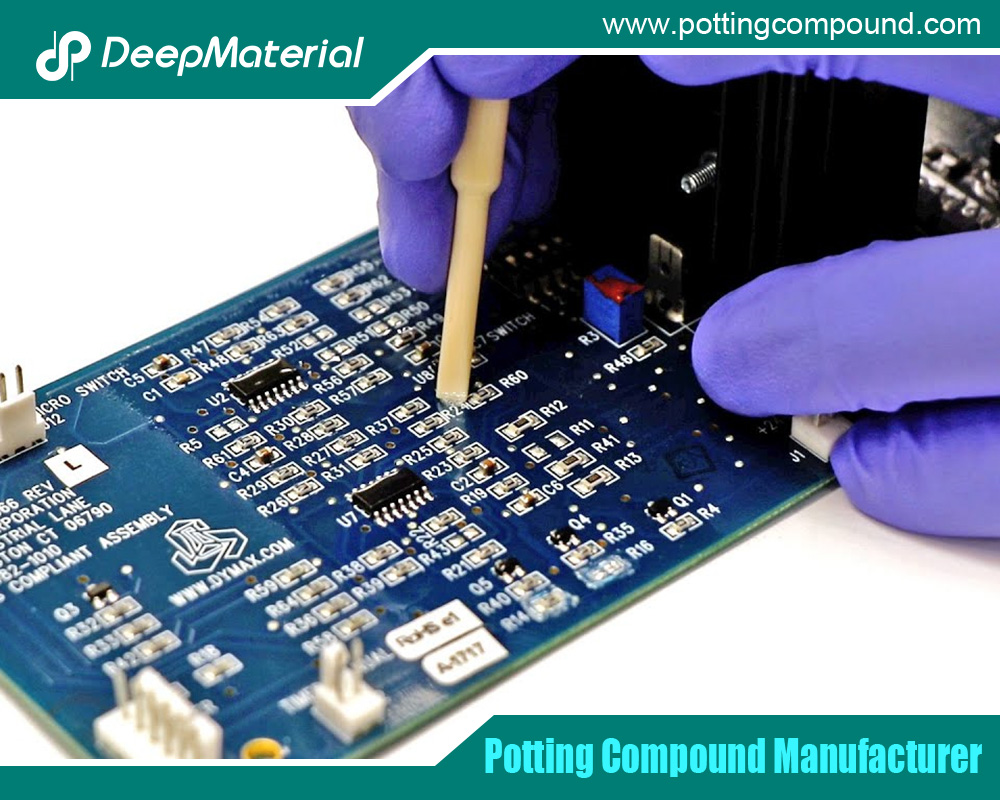

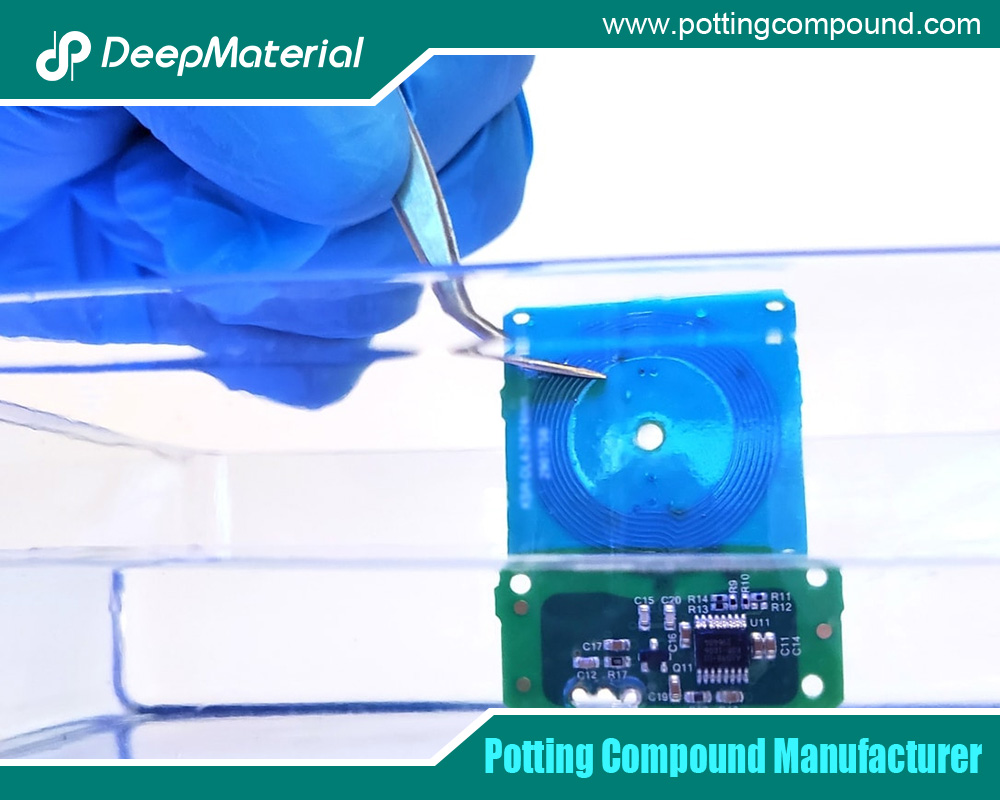

Application Methods for Silicone Conformal Coatings

The application method for silicone conformal coatings significantly impacts their performance and compliance with standards. Common methods include:

- Brushing: Manual application for small-scale or prototype PCBs. It requires skilled operators to achieve uniform thickness per IPC-CC-830 standards.

- Spraying: Automated or manual spraying is suitable for high-volume production. Aerosol or spray gun systems ensure even coverage, but viscosity and overspray must be controlled.

- Dipping: PCBs are immersed in a silicone coating bath, providing uniform coverage. This method requires precise viscosity control to avoid defects like bubbles or runs.

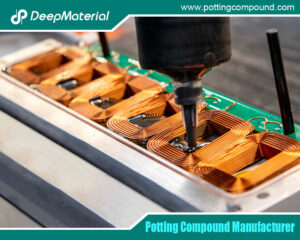

- Selective Coating: Robotic dispensing systems apply silicone coatings to specific PCB areas, minimizing waste and ensuring compliance with thickness requirements (50–210 µm per IPC-CC-830).

- UV-Curable Silicone: Some silicone formulations cure under UV light, offering rapid processing for high-throughput production. Shadow areas may require secondary curing (e.g., moisture or heat).

Each method must align with standards like IPC-CC-830, which specifies uniform coverage, absence of defects, and consistent thickness. Automated systems with in-line inspection enhance compliance with ISO 9001 quality management standards.

Standards Compliance for Silicone Conformal Coatings

Silicone conformal coatings must meet industry standards to ensure reliability and performance. Key standards include:

- IPC-CC-830 (Type SR): Qualifies silicone coatings for electrical insulation, requiring tests for dielectric strength (1,000–2,000 V/mil), moisture resistance, thermal shock (-65°C to 125°C), and visual inspection for defects.

- MIL-I-46058C: Specifies requirements for military applications, including fungus resistance, thermal cycling, and dielectric withstanding voltage. Though inactive for new designs, it remains relevant for aerospace and defense.

- UL 746E: Ensures silicone coatings meet flammability (e.g., UL 94 V-0) and electrical safety requirements for consumer and industrial electronics.

- IEC 61086: An international standard evaluating silicone coatings for adhesion, flexibility, and environmental resistance.

- ISO 9001: Ensures consistent manufacturing processes, including application, curing, and quality control for silicone coatings.

Compliance involves rigorous testing, such as:

- Visual Inspection: Checks for bubbles, pinholes, or uneven coverage.

- Thickness Measurement: Verifies coating thickness (50–210 µm for silicones) using micrometers or non-destructive methods.

- Moisture and Insulation Resistance: Tests performance under high humidity (85% RH, 85°C).

- Thermal Shock: Cycles between -55°C and 200°C to assess durability.

- Fungus Resistance: Ensures resistance to microbial growth in humid environments.

Practical Considerations for Using Silicone Conformal Coatings

When selecting and applying silicone conformal coatings, several factors should be considered:

- Environmental Conditions: Silicone is ideal for high-temperature, high-vibration, or UV-exposed environments but may not suit applications with aggressive chemical exposure.

- Application Method: Choose a method (e.g., spraying, dipping) compatible with production scale and PCB complexity. Automated systems improve consistency.

- Rework Requirements: Plan for repair processes, as silicone’s strong adhesion complicates removal. Specialized solvents or abrasive methods may be needed.

- Cost vs. Performance: Silicone’s higher cost must be justified by the application’s environmental demands. For less demanding conditions, acrylics may suffice.

- Curing Conditions: Ensure proper curing (e.g., moisture, heat, or UV) to achieve optimal properties. Environmental controls are critical for consistent results.

- Regulatory Compliance: Verify compliance with standards like IPC-CC-830 or UL 746E, especially for safety-critical applications.

Collaboration with coating suppliers and third-party testing labs can ensure optimal material selection and process validation.

Emerging Trends in Silicone Conformal Coatings

The conformal coating industry is evolving to meet the demands of modern electronics, with silicone coatings at the forefront of innovation:

- UV-Curable Silicones: Combining silicone’s properties with rapid UV curing, these coatings reduce production time while maintaining flexibility and thermal stability.

- Low-VOC Formulations: Eco-friendly silicone coatings with minimal volatile organic compounds (VOCs) align with environmental regulations.

- Flexible Electronics: Silicone’s elasticity supports coatings for flexible PCBs and wearable devices, meeting the needs of emerging technologies.

- Hybrid Silicones: Formulations combining silicone with acrylic or polyurethane properties offer tailored performance for specific applications.

- Automation and Precision: Robotic selective coating systems with real-time monitoring ensure uniform application and compliance with ISO 9001.

- Nanotechnology Integration: Silicone-based nanocoatings provide ultra-thin protection for miniaturized electronics, maintaining high performance.

These trends highlight silicone’s adaptability to next-generation electronics, from IoT devices to aerospace systems.

Comparison with Other Conformal Coatings

To contextualize silicone’s role, a brief comparison with other coatings is useful:

- Acrylics: Cost-effective and reworkable but lack silicone’s thermal and UV resistance.

- Polyurethanes: Offer superior chemical resistance but are less flexible and have a narrower temperature range.

- Epoxies: Provide robust mechanical protection but are rigid and prone to cracking under thermal cycling.

- Parylene: Excels in uniformity and biocompatibility but is costlier and requires specialized application.

Silicone strikes a balance between flexibility, thermal stability, and environmental protection, making it ideal for dynamic and high-temperature applications.

Conclusion

Silicone conformal coatings are a cornerstone of PCB protection, offering unmatched flexibility, thermal stability, and UV resistance. Their ability to perform in extreme conditions makes them indispensable in aerospace, automotive, medical, and outdoor electronics applications. While their higher cost and rework challenges require careful consideration, compliance with standards like IPC-CC-830, MIL-I-46058C, and UL 746E ensures reliability. Advances in UV-curable silicones, low-VOC formulations, and automation are expanding their utility in modern electronics. By understanding silicone’s properties, application methods, and compliance requirements, manufacturers can leverage this versatile material to enhance the durability and performance of electronic assemblies in demanding environments.

For more about why is silicone conformal coating regarded as the “Guardian Angel” of electronic components?, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB