UV Curing Potting Compound

- Electronic Potting Material Manufacturer

- August 12, 2025

- Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting, circuit board potting compound, circuit board potting compound china hotsale, circuit board potting compounds, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, conformal coating material, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating spray, conformal coating types, conformal coating waterproof, Connector Potting Compound, deepmaterial potting compound, electric motor potting compound, electric motor potting compound china OEM, electrical potting compound, electronic epoxy encapsulant potting compounds, epoxy potting compound, polyurethane potting compound, polyurethane potting compound for electronics, potting compound for electronics, potting compound for pcb, potting compound vs epoxy, potting material for electronic components, potting material for electronics, potting pcb, silicone potting compound for electronics, uv adhesive glue for glass, uv conformal coating, uv conformal coating manufacturer, UV Curable Conformal Coating, UV cure conformal coating china hotsale, UV cure conformal coating market, UV cure conformal coating supplier, UV Cure Potting Compound, UV Cured Epoxy Potting, UV Curing Encapsulants, UV curing potting compound, waterproof potting compound

UV Curing Potting Compound

In the rapidly evolving landscape of electronics and advanced manufacturing, protecting sensitive components with speed and precision is critical. UV curing potting compounds have emerged as a cutting-edge solution, combining the protective benefits of traditional potting with the efficiency of ultraviolet (UV) light curing technology. These compounds encapsulate electronic assemblies, offering insulation, environmental protection, and mechanical support, all while drastically reducing curing times compared to conventional methods.

UV curing potting compounds are transforming industries by enabling faster production cycles and enhanced reliability in applications ranging from consumer electronics to medical devices. Their ability to cure in seconds under UV light makes them ideal for high-volume manufacturing, while their robust properties ensure long-term performance. This article explores the fundamentals of UV curing potting compounds, including their properties, types, applications, benefits, and challenges. Whether you’re an engineer optimizing a production line or a manufacturer seeking innovative encapsulation solutions, this guide will provide valuable insights into leveraging these advanced materials.

What is a UV Curing Potting Compound?

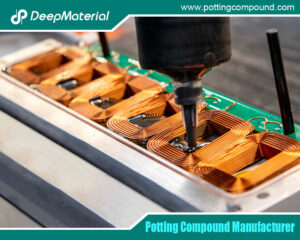

A UV curing potting compound is a resin-based material used to encapsulate electronic components, providing electrical insulation, environmental protection, and mechanical stability. Unlike traditional potting compounds that rely on heat, moisture, or chemical reactions to cure, UV curing compounds harden rapidly when exposed to ultraviolet light. This process involves pouring the liquid compound into a mold or housing containing the electronic assembly, allowing it to flow around components, and then curing it under UV light to form a solid or semi-flexible protective layer.

UV curing potting compounds typically consist of monomers, oligomers, photoinitiators, and additives. The photoinitiators absorb UV light, triggering a polymerization reaction that transforms the liquid resin into a solid within seconds. Common base materials include acrylics, epoxies, and silicones, each offering distinct properties like flexibility, hardness, or optical clarity.

Compared to traditional potting compounds, UV curing variants offer significant advantages in speed and precision, making them ideal for automated manufacturing. However, their curing mechanism requires direct UV light exposure, which can limit their use in complex or opaque assemblies. Despite this, their versatility and efficiency have made them a preferred choice in industries demanding rapid, reliable encapsulation.

Key Properties of UV Curing Potting Compounds

UV curing potting compounds are selected for their unique combination of properties, tailored to meet the demands of modern applications. Key characteristics include:

- Rapid Curing Speed: Curing in seconds under UV light, these compounds enable high-throughput production, reducing manufacturing bottlenecks.

- Electrical Insulation: High dielectric strength ensures reliable insulation, preventing electrical arcing or shorts in high-voltage components.

- Moisture and Chemical Resistance: These compounds form a barrier against water, humidity, and chemicals like solvents or oils, protecting components from corrosion.

- Mechanical Strength and Flexibility: Depending on the formulation, compounds offer rigidity for structural support or flexibility to absorb vibrations and thermal expansion.

- Optical Clarity and UV Stability: Many UV curing compounds are optically clear, ideal for applications like LEDs or displays, and resist yellowing under UV exposure.

These properties make UV curing potting compounds highly adaptable, providing robust protection while meeting the stringent requirements of industries like electronics, automotive, and medical manufacturing.

Types of UV Curing Potting Compounds

UV curing potting compounds are available in various formulations, each designed for specific performance needs. The main types include:

- Acrylic-Based Compounds: Known for their fast curing and optical clarity, acrylics are ideal for applications requiring transparency, such as LEDs or displays. They offer good adhesion and moisture resistance. Pros: Rapid curing, clear finish, cost-effective.

Cons: Limited flexibility, moderate chemical resistance.

- Epoxy-Based Compounds: These provide excellent hardness, chemical resistance, and adhesion, suitable for rigid encapsulation in industrial or automotive electronics. Pros: High strength, durable, excellent insulation.

Cons: Brittle, slower UV curing compared to acrylics.

3. Silicone-Based Compounds: Offering flexibility and thermal stability, silicones are ideal for high-temperature or dynamic environments, such as outdoor sensors or automotive components. Pros: Wide temperature range, flexible, UV resistant.

Cons: Higher cost, lower mechanical strength.

4.Hybrid Compounds: Combining properties of acrylics, epoxies, or silicones, hybrids offer tailored performance, such as enhanced thermal conductivity or flame retardancy, for niche applications. Pros: Customized properties, versatile.

Cons: Complex formulations, higher cost.

Each type is formulated to address specific electrical, environmental, or mechanical requirements, allowing manufacturers to select the optimal compound for their application.

Applications of UV Curing Potting Compounds

UV curing potting compounds are used across diverse industries, protecting critical components in demanding environments. Key applications include:

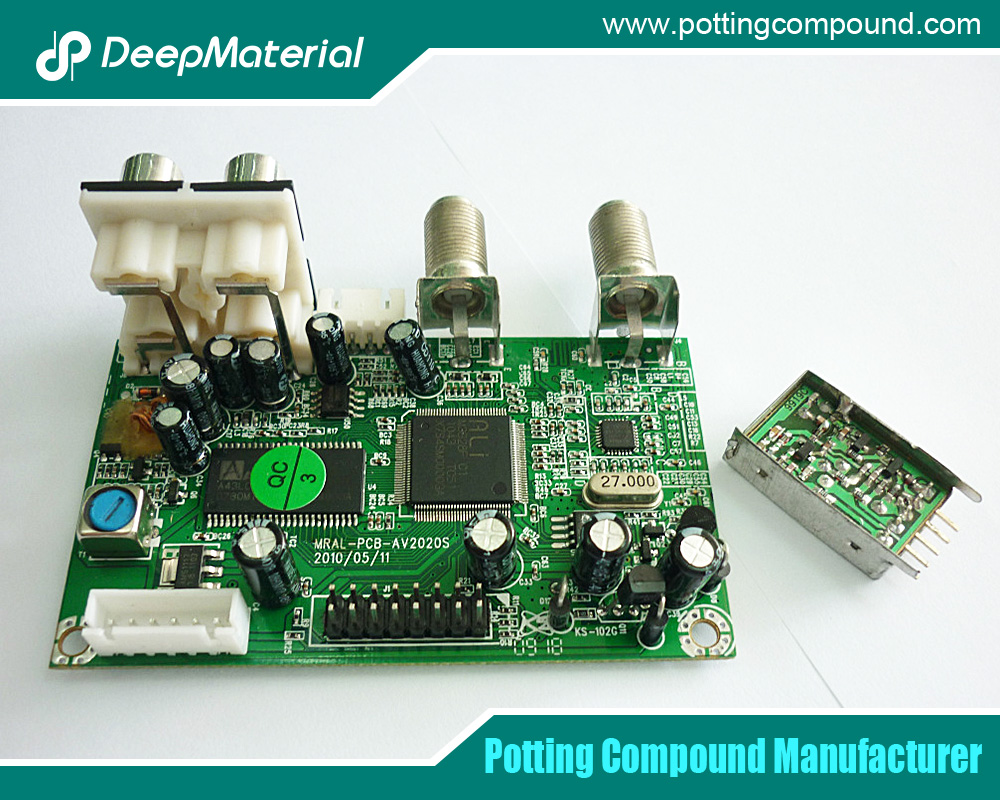

- Electronics: These compounds encapsulate printed circuit boards (PCBs), sensors, and connectors in consumer devices like smartphones, wearables, and IoT gadgets, ensuring protection against moisture and vibrations.

- Automotive and Aerospace: Potting compounds protect engine control units (ECUs), sensors, and avionics from heat, chemicals, and mechanical stress, ensuring reliability in harsh conditions.

- Medical Devices: UV curing compounds are used in diagnostic tools, wearables, and implantable devices, offering biocompatibility and protection in sterile or humid environments.

- Optical and Display Technologies: Optically clear compounds encapsulate LEDs, touchscreens, and optical sensors, maintaining clarity and resisting UV degradation in displays or lighting systems.

- Renewable Energy Systems: Solar panels and wind turbine electronics benefit from UV curing potting for resistance to weather, UV exposure, and temperature fluctuations.

These applications demonstrate the versatility of UV curing potting compounds, which are tailored to meet the unique challenges of each industry while enabling efficient production.

Benefits of UV Curing Potting Compounds

UV curing potting compounds offer several advantages, making them a preferred choice for modern manufacturing:

- Fast Production Cycles: Curing in seconds under UV light, these compounds streamline production, reducing downtime and increasing throughput.

- Enhanced Precision and Control: UV curing allows precise control over the curing process, minimizing defects and ensuring consistent encapsulation.

- Environmental and Safety Advantages: UV curing produces minimal volatile organic compounds (VOCs) and requires no heat, reducing energy consumption and worker exposure to fumes.

- Versatility in Diverse Applications: Available in various formulations, these compounds meet the needs of industries requiring optical clarity, flexibility, or high strength.

These benefits make UV curing potting compounds an innovative solution for manufacturers seeking efficiency, reliability, and sustainability in encapsulation processes.

Challenges and Considerations

Despite their advantages, UV curing potting compounds present some challenges that must be addressed:

- Limited Penetration Depth: UV light cannot penetrate opaque or thick assemblies, restricting curing to surface-level or transparent applications. Shadowed areas may require secondary curing methods.

- Equipment and Cost Requirements: UV curing systems, such as lamps or LEDs, add upfront costs, and high-performance compounds can be expensive.

- Material Compatibility: Some compounds may not adhere well to certain substrates, risking delamination if compatibility is not tested.

- Environmental Exposure Limitations: While many compounds resist moisture and chemicals, prolonged UV exposure may degrade certain formulations unless UV stabilizers are included.

Manufacturers can mitigate these challenges by selecting appropriate compounds, investing in suitable curing equipment, and collaborating with suppliers to ensure compatibility and performance.

How to Choose the Right UV Curing Potting Compound

Selecting the appropriate UV curing potting compound involves evaluating several factors:

- Application Requirements: Determine the need for optical clarity, flexibility, or high strength based on the component’s function.

- Environmental Conditions: Assess exposure to moisture, chemicals, UV light, or temperature extremes to choose a resistant formulation.

- Electrical Properties: Ensure the compound’s dielectric strength meets the voltage demands of the application.

- Certifications: Look for compounds meeting industry standards, such as UL, RoHS, or ISO, for regulatory compliance.

- Production Process: Confirm compatibility with UV curing equipment and production line constraints.

- Budget: Balance performance with cost, especially for high-volume manufacturing.

Testing samples and consulting with suppliers can help identify the best compound, ensuring optimal protection and efficiency for your application.

Conclusion

UV curing potting compounds represent a groundbreaking advancement in encapsulation technology, offering rapid curing, robust protection, and versatility across industries. From electronics to medical devices, their ability to combine efficiency with reliability makes them indispensable in modern manufacturing. By understanding their properties, types, and applications, manufacturers can harness these compounds to enhance the performance and durability of their products.

As innovation continues, trends like eco-friendly formulations and advanced hybrid compounds promise to further elevate the utility of UV curing potting compounds. For engineers and manufacturers, exploring the range of options available today is a vital step toward optimizing production and building resilient devices. Consult with suppliers or test samples to find the perfect solution, ensuring your components thrive in even the most demanding environments.

For more about choosing the Top Industrial Electronic Adhesives Suppliers, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB