The Characteristics of Thermal Conductivity, Waterproofness and Shock Resistance of LED Potting Compounds

- Electronic Potting Material Manufacturer

- November 13, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting, circuit board potting compound, circuit board potting compound china hotsale, circuit board potting compound china OEM, circuit board potting compounds, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, Conformal Coating Material Manufacturer, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating silicone manufacturer, Connector Potting Compound, deepmaterial potting compound, deepmaterial potting compound manufacturer, electric motor potting compound, electric motor potting compound market, electrical potting compound, electronic epoxy encapsulant potting compounds, epoxy encapsulation electronic components, epoxy encapsulation for photovolatics, LED Potting Compounds, LED Potting Compounds Manufacturer, LED Potting Compounds Supplier, pcb encapsulation epoxy, Potting Compounds, potting material for electronic components, UV curing potting compound

The Characteristics of Thermal Conductivity, Waterproofness and Shock Resistance of LED Potting Compounds

Light-emitting diodes (LEDs) have revolutionized lighting and display technologies, offering energy efficiency, longevity, and versatility in applications ranging from automotive headlights to consumer electronics and outdoor signage. However, LEDs are sensitive electronic components that require protection from environmental stressors such as moisture, dust, mechanical shocks, and thermal fluctuations. This is where potting compounds come into play. Potting compounds are specialized materials used to encapsulate LEDs, providing a protective barrier that enhances durability, performance, and lifespan.

Potting involves filling the voids around LED components with a liquid resin that cures into a solid or semi-solid form. The choice of potting compound is critical, as it directly influences the LED’s optical, thermal, and mechanical properties. Common types include silicone, epoxy, and polyurethane adhesives, each with unique characteristics tailored to specific needs. For instance, silicone adhesives are prized for their optical clarity and flexibility, epoxy for their rigidity and chemical resistance, and polyurethane for their elasticity and environmental resilience.

The key characteristics of LED potting compounds include high light transmittance, which ensures minimal light loss; yellowing resistance to maintain clarity over time; thermal conductivity for efficient heat dissipation; waterproofness to prevent moisture ingress; and shock resistance to withstand vibrations and impacts. These properties are essential because LEDs generate heat during operation, and poor management can lead to reduced efficiency or failure. Moreover, in outdoor or harsh environments, exposure to UV light, chemicals, or physical stress can degrade performance.

This article explores these characteristics in detail, comparing how silicone, epoxy, and polyurethane potting compounds perform. By understanding these attributes, engineers and manufacturers can select the optimal material for their LED applications, balancing factors like cost, processing ease, and long-term reliability. Drawing from industry insights, we will delve into the science behind each property and provide practical examples.

High Light Transmittance

High light transmittance is one of the most crucial characteristics for LED potting compounds, as LEDs rely on efficient light output to function effectively. Transmittance refers to the ability of the material to allow light to pass through without significant absorption or scattering. In LED encapsulation, a potting compound with high transmittance ensures that the emitted light reaches its intended target with minimal loss, maintaining brightness and color accuracy. This is particularly important in applications like display screens, automotive lighting, and architectural illumination, where optical performance directly impacts user experience.

Silicone adhesives excel in this area due to their inherent optical clarity. Composed of silicon-oxygen chains, silicones have a refractive index close to that of air and glass, reducing light refraction and enabling transmittance rates often exceeding 90% in the visible spectrum. For example, crystal-clear silicone potting compounds are designed specifically for LED strips and modules, forming a transparent layer that protects without dimming the light. Their molecular structure resists degradation, ensuring consistent transmittance over time. Additionally, silicones can be formulated to be non-yellowing, further preserving optical properties under prolonged exposure to heat or UV radiation.

Epoxy adhesives also offer good light transmittance, typically around 80-90%, making them suitable for certain LED applications where clarity is needed alongside mechanical strength. Epoxies are cross-linked polymers that cure into a hard, glass-like material, providing a stable optical medium. However, their transmittance can be lower than silicones due to potential impurities or additives that scatter light. In LED assembly, optically clear epoxies are used for potting where high bonding strength is required, such as in high-power LEDs that need robust encapsulation. Despite this, epoxies may not match silicones in flexibility, which can affect transmittance if cracking occurs under stress.

Polyurethane adhesives provide moderate to high light transmittance, often in the 85-95% range for optically clear formulations. Polyurethanes are versatile, with their isocyanate and polyol components allowing customization for clarity. They form a flexible, elastic matrix that minimizes light distortion from movement or expansion. In LED potting, polyurethanes are favored for applications requiring a balance of optics and durability, such as flexible LED strips or outdoor lights exposed to temperature variations. Their ability to incorporate UV stabilizers enhances transmittance stability, though they may not achieve the ultra-high clarity of specialized silicones.

Overall, selecting a potting compound with high light transmittance involves considering the LED’s wavelength output—blue and white LEDs, for instance, benefit from materials that transmit across the 400-700 nm range. Factors like thickness of the potting layer and curing conditions also influence final transmittance. In practice, silicones are often the go-to for high-end optical applications, while epoxies and polyurethanes serve where additional mechanical properties are prioritized.

Yellowing Resistance

Yellowing resistance is vital for LED potting compounds, as discoloration over time can reduce light output and alter color rendering, leading to diminished performance in lighting systems. Yellowing typically occurs due to oxidation, UV exposure, or thermal degradation, where the material’s polymers break down, forming chromophores that absorb visible light. For LEDs, which often operate continuously in challenging environments, a potting compound that resists yellowing ensures long-term reliability and aesthetic consistency.

Silicone adhesives demonstrate exceptional yellowing resistance, thanks to their stable siloxane backbone that withstands UV radiation and high temperatures without degrading. Non-yellowing silicones are formulated with minimal additives that could catalyze discoloration, maintaining clarity for years. In LED applications, such as outdoor signage or automotive lamps, silicones prevent the hazy yellow tint that plagues lesser materials, preserving the cool white or colored light output. Their resistance extends to thermal cycling, where temperatures up to 200°C do not induce yellowing, making them ideal for high-power LEDs that generate significant heat. Epoxy adhesives have moderate yellowing resistance, but they are more susceptible to UV-induced discoloration compared to silicones. Standard epoxies can yellow over time, especially in outdoor settings, due to the aromatic rings in their structure that absorb UV light. However, UV-stabilized epoxies improve this, offering better resistance for indoor or controlled environments. In LED potting, epoxies are used where yellowing is less critical, such as in encapsulated modules with protective casings, leveraging their superior adhesion and hardness instead. Thermal resistance up to 100°C helps, but prolonged exposure can still lead to slight tinting.

Polyurethane adhesives offer good yellowing resistance, particularly aliphatic formulations that lack aromatic groups prone to UV degradation. These materials maintain transparency under sunlight, making them suitable for solar-powered LEDs or exterior lighting. Polyurethanes’ elasticity aids in resisting cracking that could expose inner layers to oxidants, further preventing yellowing. In practice, they are chosen for flexible LED applications where movement might stress rigid materials like epoxies. Additives like hindered amine light stabilizers (HALS) enhance their performance, ensuring color stability over thousands of hours.

To evaluate yellowing resistance, industry standards like ASTM D1925 measure yellowness index before and after accelerated aging tests. For LEDs, compounds with a low delta-E (color change) are preferred. Silicone stands out for premium applications, while enhanced epoxies and polyurethanes provide cost-effective alternatives with acceptable resistance.

Thermal Conductivity

Thermal conductivity is a key property in LED potting compounds, as LEDs convert only a portion of electrical energy to light, with the rest dissipating as heat. Poor heat management can cause junction temperature rises, reducing efficiency, lifespan, and color consistency. A potting compound with high thermal conductivity acts as a heat sink, transferring heat away from the LED die to the substrate or ambient air.

Silicone adhesives provide good thermal conductivity, often enhanced with fillers like boron nitride or alumina to reach 1-2 W/m·K. Their soft, conformal nature ensures intimate contact with LED components, minimizing thermal resistance. In high-power LED arrays, silicones dissipate heat effectively while remaining flexible, preventing stress from thermal expansion. They also resist high temperatures long-term, up to 200°C, without losing conductivity.

Epoxy adhesives boast high thermal conductivity, typically 0.5-1.5 W/m·K, due to their dense, rigid structure that facilitates heat transfer. Filled epoxies can exceed 2 W/m·K, making them suitable for demanding LED applications like automotive headlights. Their excellent adhesion ensures low interfacial resistance, but rigidity can lead to cracks under thermal shock. Polyurethane adhesives offer moderate thermal conductivity, around 0.3-1 W/m·K, but their elasticity makes them resilient to thermal cycling. They perform well in low to mid-power LEDs, where shock resistance is more critical than peak conductivity. Formulations with conductive fillers improve this for specific uses.

Thermal conductivity is measured via ASTM E1461, and for LEDs, compounds should balance conductivity with other properties to avoid hotspots.

Waterproofness

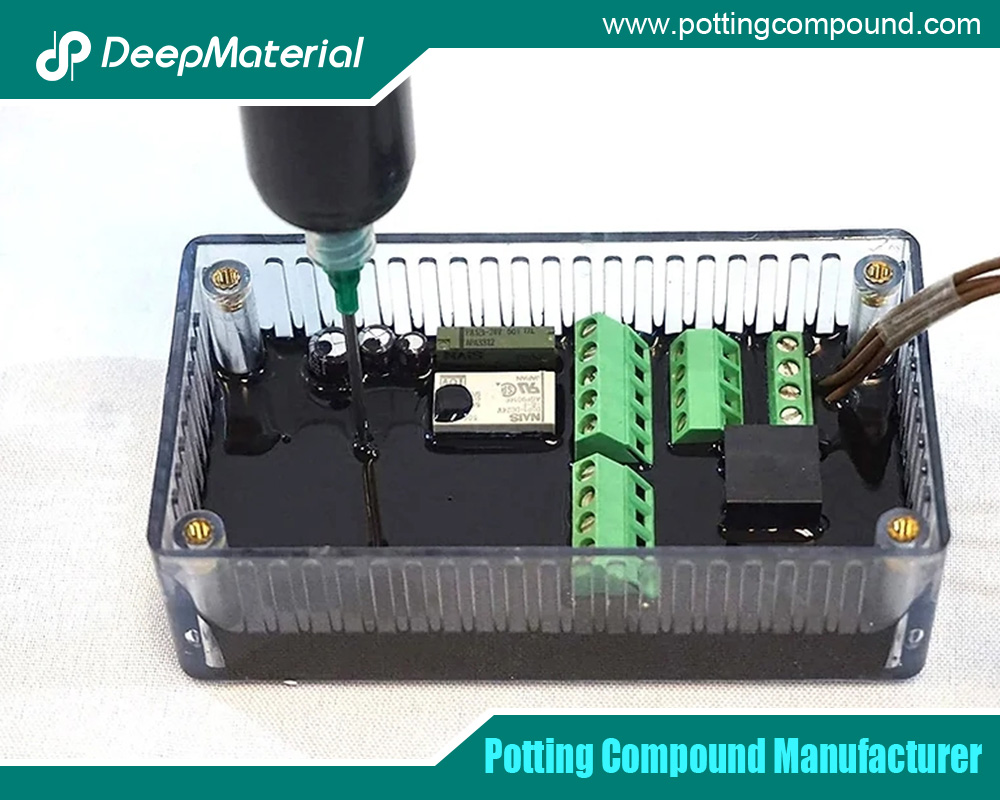

Waterproofness in LED potting compounds prevents moisture ingress, which can cause corrosion, short circuits, or delamination. LEDs in humid or wet environments, like underwater lights or outdoor fixtures, rely on this property for reliability.

Silicone adhesives are highly waterproof, forming a hydrophobic barrier with low water absorption (<0.5%). Their flexibility seals gaps effectively. Epoxy adhesives provide excellent waterproofness through their impermeable, hard matrix, resisting chemicals too. Polyurethane adhesives excel in waterproofness, with elastic properties that maintain seals under movement. They are ideal for marine LEDs.IP ratings like IP67 indicate waterproof performance.

Shock Resistance

Shock resistance protects LEDs from vibrations, impacts, and mechanical stresses in applications like vehicles or industrial equipment.

Silicone adhesives are soft and shock-resistant, absorbing energy without cracking. Epoxy adhesives offer high hardness but can be brittle; toughened versions improve resistance. Polyurethane adhesives provide outstanding shock resistance due to elasticity.

Other Characteristics

Additional properties include chemical resistance (strong in epoxies), insulation (universal), and curing speed (fast in polyurethanes).

Conclusion

LED potting compounds like silicone, epoxy, and polyurethane offer tailored characteristics to meet diverse needs, ensuring optimal performance and longevity. Selecting the right one depends on application-specific requirements.

For more about the characteristics of thermal conductivity, waterproofness and shock resistance of LED potting compounds, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB