Revealing the Wide Range of Application Scenarios of LED Potting Compounds

- Electronic Potting Material Manufacturer

- November 4, 2025

- Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting, circuit board potting compound, circuit board potting compound china hotsale, circuit board potting compound china OEM, circuit board potting compound hotsale, circuit board potting compounds, conformal coating for electronics, conformal coating for pcb, conformal coating spray, Connector Potting Compound, deepmaterial potting compound, deepmaterial potting compound manufacturer, electric motor potting compound, electrical potting compound, electronic epoxy encapsulant potting compounds, epoxy encapsulation for photovolatics, epoxy encapsulation for photovolatics and oleds, epoxy encapsulation led, led encapsulation epoxy, LED Potting Compound, LED Potting Compounds, LED Potting Compounds Manufacturer, LED Potting Compounds Supplier, LED Potting Glue, LED Potting Glue Manufacturer, LED Potting Glue Market, LED Potting Glue Supplier, LED Potting Glue Types, led uv glue adhesive, pcb encapsulation epoxy, pcb potting, polyurethane potting compound for electronics, potting compound, potting material for electronic components, potting material for electronics, potting pcb, UV curing potting compound, what is pcb potting

Revealing the Wide Range of Application Scenarios of LED Potting Compounds

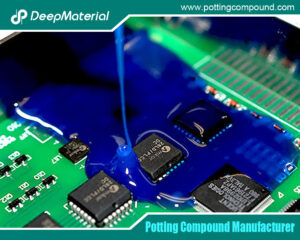

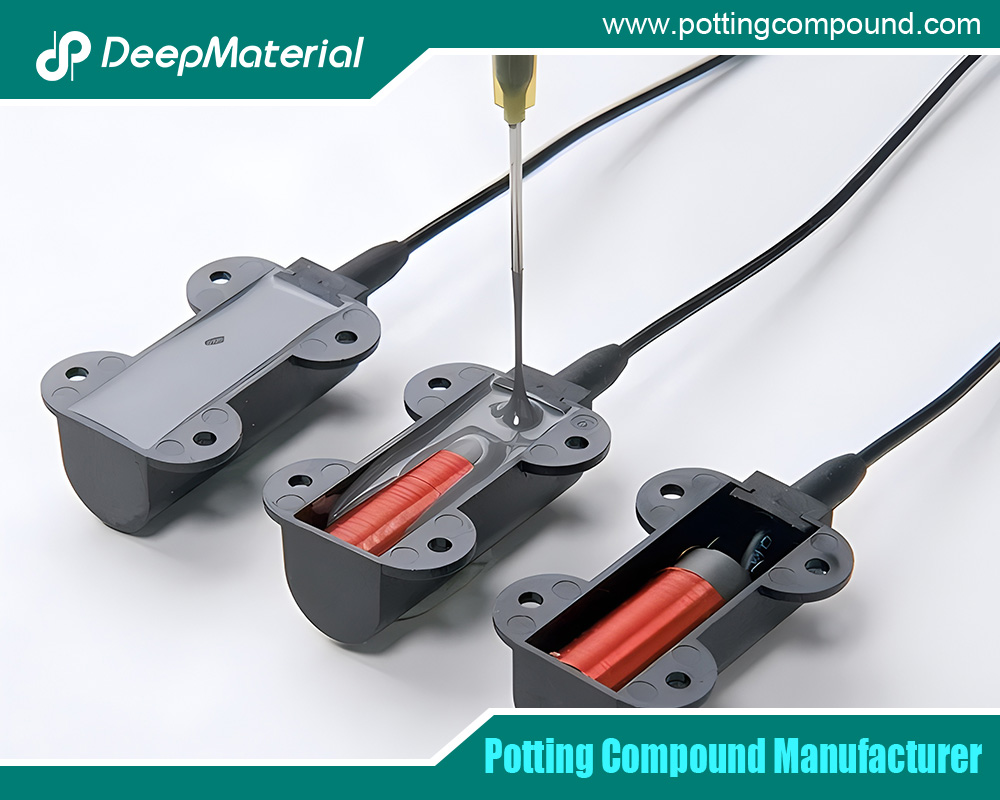

Light-emitting diodes (LEDs) have become ubiquitous in modern technology, powering everything from household bulbs to massive digital billboards. However, these semiconductor devices are vulnerable to environmental factors like moisture, dust, vibrations, and thermal stress, which can compromise their performance and longevity. This is where LED potting compounds play a pivotal role. Potting compounds are specialized resins that encapsulate LED components, providing insulation, protection, and enhanced durability. They are typically applied in liquid form and cure into a solid or flexible barrier, sealing sensitive electronics from external threats.

The primary types of LED potting compounds include silicones, epoxies, and polyurethanes, each offering distinct advantages. Silicone potting compounds, for instance, are renowned for their high light transmittance, flexibility, and resistance to extreme temperatures and UV radiation. They are ideal for fixing and insulating electronic components, protecting PCBs from humidity and moisture, and are commonly used in circuit modules, automotive electronic modules, and LED displays. Epoxies provide rigid protection with excellent adhesion and chemical resistance, making them suitable for high-mechanical-stress environments. Polyurethanes offer elasticity, superior shock absorption, and waterproofing, excelling in applications requiring flexibility and environmental resilience.

The application scenarios for these compounds are vast, spanning LED displays for advertising and information systems, lighting fixtures for residential and commercial use, power modules for efficient energy management, and beyond. In LED displays, potting ensures optical clarity and weatherproofing; in lighting fixtures, it enhances heat dissipation and longevity; in power modules, it provides electrical insulation; and in other fields like automotive and marine, it safeguards against harsh conditions. As LED technology evolves, with demands for higher brightness, energy efficiency, and miniaturization, the role of potting compounds becomes even more critical. This article delves into these scenarios, highlighting how different compounds are tailored to specific needs, drawing on industry examples and innovations to illustrate their practical impact.

LED Displays

LED displays represent one of the most prominent application scenarios for LED potting compounds, where the need for durability, optical performance, and environmental protection is paramount. These displays, used in stadium scoreboards, digital billboards, airport information panels, and retail signage, are often exposed to outdoor elements like rain, wind, dust, and temperature fluctuations. Potting compounds encapsulate the LED modules, preventing moisture ingress that could cause short circuits or corrosion, while maintaining light output efficiency.

Silicone potting compounds are particularly favored in LED displays due to their crystal-clear transparency and non-yellowing properties, which ensure consistent color rendering over time. For example, in outdoor LED displays, silicone resins like Chem-Set 412 provide a flexible, waterproof seal that protects against UV degradation and thermal cycling from -55°C to 204°C, making them suitable for high-traffic areas like Times Square billboards or highway signs. Their low viscosity allows easy flow into tight spaces, fixing components securely while insulating against electrical faults. In flexible LED screens used for curved installations or wearable tech, silicones’ elasticity prevents cracking under bending stress.

Epoxy potting compounds offer a rigid alternative for LED displays requiring high mechanical strength. In high-resolution indoor displays, such as those in conference rooms or museums, epoxies like Epic S7512 encapsulate LED chips to insulate wire bonds from vibration and thermal shock. Their superior adhesion bonds tightly to PCBs, providing tamper-proofing and dimensional stability, which is crucial for maintaining pixel alignment in video walls. However, epoxies are less flexible, so they are often used in static installations where robustness trumps adaptability.

Polyurethane compounds shine in scenarios demanding shock resistance and waterproofing, such as portable LED displays for events or transportation hubs. Products like Epic S7475, with UL 94 V-0 flame retardancy, are applied to outdoor strip lighting integrated into displays, offering flexibility over wide temperature ranges and excellent moisture resistance. In humid environments, polyurethanes prevent mold growth and hydrolysis, extending display lifespan. For instance, in airport LED boards exposed to constant vibrations from foot traffic, polyurethane encapsulation absorbs impacts, reducing failure rates.

Overall, in LED displays, potting compounds not only protect but also enhance performance by improving heat dissipation—critical for preventing lumen depreciation. With the rise of fine-pitch LEDs for 4K/8K resolutions, compounds with low shrinkage and high thermal conductivity, like thermally enhanced silicones (up to 3.0 W/m·K), are increasingly used to manage heat in densely packed modules. Case studies show that properly potted displays can achieve IP67 ratings, surviving extreme weather and reducing maintenance costs by up to 50%.

LED Lighting Fixtures

LED lighting fixtures encompass a broad range of products, from street lamps and floodlights to indoor downlights and decorative strips, all benefiting from potting compounds to ensure reliability in diverse environments. These fixtures often operate continuously, generating heat that must be managed, while facing exposure to humidity, chemicals, or physical abuse. Potting provides a protective envelope that insulates electrical connections, dissipates heat, and seals against contaminants.

In outdoor lighting fixtures like street lights and traffic signals, silicone potting compounds are extensively used for their long-term stability and waterproofing. They protect LED arrays from rain and humidity, as seen in applications where two-component silicones encapsulate headlamps and taillights in vehicles, extending service life in harsh weather. Silicone’s high-temperature resistance (up to 200°C) prevents degradation in hot climates, while its flexibility accommodates thermal expansion without cracking. For example, in solar-powered street lights, silicone potting insulates battery-integrated LEDs, shielding from moisture and dust in remote areas.

Epoxy compounds are preferred for rigid, high-impact lighting fixtures, such as industrial high-bay lights or emergency signaling. Their mechanical strength ruggedizes circuits, as in the use of 832HD epoxy to protect delicate LEDs in flashlights and vehicle lights. In automotive lighting, epoxies provide corrosion protection and thermal stability, ensuring headlights withstand road vibrations and salt exposure. Their low exotherm during curing makes them suitable for mass production of LED bulbs with integrated drivers.

Polyurethane potting excels in flexible and underwater lighting fixtures, offering elasticity and UV resistance. In pool and spa lighting, compounds like UR5634 encapsulate LEDs to resist mold and water, maintaining optical clarity indoors or outdoors. For decorative strip lighting in architectural applications, polyurethanes like Epic S7144 provide shock absorption, ideal for installations subject to wind or seismic activity. Their hydrolytic stability ensures longevity in humid settings, such as greenhouse LEDs for plant growth.

Innovations in LED fixtures, like smart lighting with IoT integration, demand potting compounds with enhanced thermal management. Thermally conductive silicones are used in high-lumen fixtures to prevent overheating, while UV-curable systems from MasterBond allow rapid assembly for shadowed areas in complex designs. In summary, potting in lighting fixtures not only boosts IP ratings but also supports energy efficiency by maintaining optimal operating temperatures.

LED Power Modules

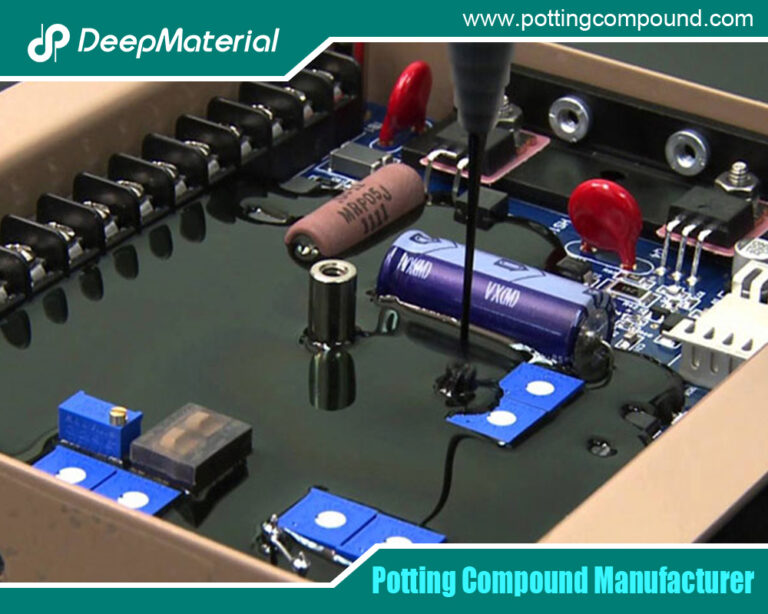

LED power modules, including drivers, converters, and supplies, are the backbone of LED systems, converting AC to DC and regulating current. These modules generate significant heat and are susceptible to electrical surges, making potting compounds essential for insulation, heat transfer, and protection.

Silicone potting is widely applied in LED power modules for its electrical insulation and thermal conductivity. In high-voltage supplies, silicones like SI8230 fill tight spaces, providing a barrier against arcing and moisture. Their low modulus reduces stress on components during thermal cycling, suitable for dimmable drivers in smart homes.

Epoxy resins dominate in modules requiring rigid encapsulation, such as outdoor power supplies. Epic R1055/H5083, with UL recognition, pots high-voltage coils, offering exceptional dielectric strength and low viscosity for penetration. In LED drivers for signage, epoxies ensure stability under constant operation.

Polyurethanes provide flexible protection in modules exposed to vibrations, like those in automotive or industrial settings. Epic S7634, with UL 94 V-0 rating, operates from -40°C to 130°C, ideal for LED drivers in harsh environments. Their moisture resistance prevents failures in humid power enclosures.

Potting enhances module efficiency by improving thermal dissipation, crucial for compact designs.

Other Fields

Beyond core LED applications, LED potting compounds extend to automotive electronics, circuit modules, medical devices, and marine systems. In automotive modules, silicones protect ECUs and sensors from heat and vibrations. Polyurethanes are used in emergency signaling for shock resistance. In general circuit modules, epoxies provide chemical corrosion resistance. Emerging uses include solar panels and wearables, where flexible compounds enable innovative designs.

Conclusion

LED potting compounds are indispensable across displays, lighting, power modules, and diverse fields, tailoring protection to specific challenges. As LEDs advance, these materials will evolve, supporting sustainable and efficient technologies.

For more about revealing the wide range of application scenarios of LED potting compounds, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?