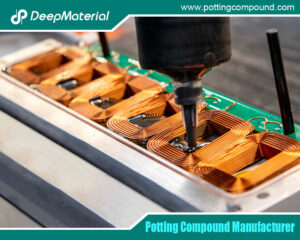

Potting Compound For Relays, Resistors, And Capacitors

Potting compounds protect electronic components from environmental factors such as moisture, vibration, thermal shock, and corrosion. When it comes to components like relays, resistors, and capacitors, selecting the appropriate potting compound is essential for optimal performance and longevity. This article will explore the considerations for choosing potting compounds for these vital electronic elements.

Understanding the Components

Before diving into potting compound selection, it’s essential to understand the function and characteristics of relays, resistors, and capacitors.

- Relays are electrically operated switches that control circuits with high currents or voltages. They consist of a coil, an armature, and one or more contacts. Relays are commonly used in various automotive, industrial control, and telecommunications applications.

- Resistors: Resistors are passive components that limit the flow of electric current. They are ubiquitous in electronic circuits and come in various types, such as carbon film, metal film, and wire-wound resistors. The choice of the resistor depends on factors like power rating, tolerance, and temperature coefficient.

- Capacitors: Capacitors store and release electrical energy as an electrostatic field. They come in different types, including ceramic, electrolytic, and tantalum capacitors. Capacitors are used for smoothing power supplies, filtering signals, and coupling signals in electronic circuits.

Factors to Consider When Choosing Potting Compounds

Several factors should be considered when selecting potting compounds for relays, resistors, and capacitors:

- Compatibility: The potting compound should be compatible with the materials used in the components. For example, certain potting compounds may interact chemically with the leads or terminals of capacitors, leading to performance issues or damage.

- Thermal Properties: Electronic components, especially relays and resistors, can generate heat during operation. Therefore, choosing a potting compound with excellent thermal conductivity and stability is crucial to dissipate heat effectively and prevent overheating.

- Electrical Insulation: Potting compounds should provide electrical insulation to prevent short circuits and ensure the reliable operation of electronic circuits. Selecting a compound with high dielectric strength and resistance to breakdown under high voltages is essential.

- Mechanical Protection: Relays, resistors, and capacitors may be subjected to mechanical stress due to vibration, shock, or handling during assembly. The potting compound should offer robust mechanical protection to prevent component damage.

- Chemical Resistance: Electronic components may be exposed to various chemicals in their operating environment. Potting compounds should resist degradation when exposed to oils, solvents, fuels, and other potentially corrosive substances.

Types of Potting Compounds

Several types of potting compounds are commonly used for encapsulating relays, resistors, and capacitors:

- Epoxy Resins: Epoxy resins are widely used for potting electronic components due to their excellent electrical insulation, thermal conductivity, and mechanical strength. They offer good adhesion to various substrates and can be formulated to withstand various temperatures and environmental conditions.

- Silicone Rubber: Silicone rubber potting compounds are known for their flexibility, thermal stability, and resistance to moisture and chemicals. They are often used in applications requiring high flexibility and thermal cycling resistance.

- Polyurethane Resins: Polyurethane potting compounds protect against moisture, chemicals, and mechanical shock. They offer good adhesion to different substrates and can be formulated for specific performance requirements.

- Acrylic Resins: Acrylic potting compounds provide good electrical insulation properties and resistance to moisture and thermal cycling. They are often used in applications where fast curing times and low shrinkage are essential.

Conclusion

Choosing the suitable potting compound is essential for protecting relays, resistors, and capacitors from environmental factors and ensuring the reliable operation of electronic circuits. By considering compatibility, thermal properties, electrical insulation, mechanical protection, and chemical resistance, electronics designers can select the most suitable potting compound for their specific application requirements. Whether epoxy resins, silicone rubber, polyurethane resins, or acrylic resins, each potting compound offers unique properties to meet the diverse needs of electronic components in various industries.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

Common Mistakes to Avoid When Applying Conformal Coating

Common Mistakes to Avoid When Applying Conformal Coating In the world of electronics manufacturing, the difference between a product that lasts a decade and

How Does Potting and Encapsulation Protect Electronic Components?

How Does Potting and Encapsulation Protect Electronic Components? In an increasingly electrified and connected world, electronic components are deployed in environments ranging from the

How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation Potting, the process of encapsulating a printed circuit board (PCB)

How to Choose the Right Potting Material for Your PCB

How to Choose the Right Potting Material for Your PCB Printed Circuit Boards (PCBs) form the backbone of modern electronics, but their delicate

Basic Knowledge, Methods and Materials about Electronic Encapsulation

Basic Knowledge, Methods and Materials about Electronic Encapsulation In an era defined by ubiquitous electronics—from the smartphone in your pocket to the sensor monitoring

Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics The modern automobile has undergone a radical transformation, evolving from a predominantly mechanical machine