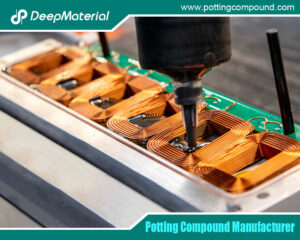

Potting Compound For Automotive & Coil Assemblies

Ensuring durability, reliability, and performance is paramount in the intricate world of automotive and coil assemblies. The potting compound is one often-overlooked component that plays an important role in achieving these qualities. A potting compound, an encapsulant material, protects electronic components from environmental factors such as moisture, chemicals, vibration, and temperature extremes. Due to their numerous benefits, potting compounds have become increasingly prevalent in the automotive and coil assembly industry. Let’s delve into the advantages of potting compounds and their significance in these applications.

Enhanced Protection Against Environmental Stressors

Automotive and coil assemblies are subjected to harsh operating conditions, including exposure to moisture, chemicals, and extreme temperatures. Without adequate protection, sensitive electronic components within these assemblies can deteriorate prematurely, leading to malfunctions and system failures. The potting compound acts as a protective barrier, encapsulating and shielding the components from external elements. This not only extends the lifespan of the assemblies but also ensures consistent performance under diverse environmental conditions.

Improved Mechanical Stability

Vibration and mechanical shock are common challenges automotive and coil assemblies face, especially those installed in vehicles or industrial machinery. These dynamic forces can cause components to loosen or dislodge over time, compromising the assembly’s integrity. Potting compound mitigates this risk by providing structural support and anchoring the components firmly. The potting compound minimizes movement and enhances mechanical stability by encapsulating the entire assembly, reducing the likelihood of damage or failure due to mechanical stress.

Thermal Management

Effective thermal management is necessary to maintain the optimal operating temperature of electronic components within automotive and coil assemblies. Excessive heat can degrade performance, reduce efficiency, and ultimately lead to component failure. Potting compounds aid in thermal dissipation by conducting heat away from the encapsulated components and dissipating it into the surrounding environment. This helps to regulate temperature levels and prevent overheating, ensuring reliable operation even in demanding thermal conditions.

Chemical Resistance

Automotive and coil assemblies may be exposed to various chemicals and fluids, such as automotive fluids, cleaning agents, and industrial solvents. Prolonged exposure to these substances can corrode or damage unprotected electronic components, compromising the assembly’s overall functionality. Potting compounds offer excellent chemical resistance, forming a barrier that shields the components from corrosive agents and chemical contaminants. This preserves the assembly’s integrity, reduces maintenance requirements, and enhances longevity.

Customization and Flexibility

Potting compounds are available in various formulations, allowing customization to suit specific application requirements. Whether adjusting the viscosity for optimal flow characteristics or modifying the cure time to accommodate production schedules, manufacturers can tailor the potting compound to meet their needs. Furthermore, potting compounds can be applied using various techniques such as casting, injection molding, or encapsulation, providing flexibility in manufacturing processes and assembly designs.

Conclusion

In conclusion, potting compounds are vital in enhancing automotive and coil assemblies’ durability, reliability, and performance. By providing protection against environmental stressors, improving mechanical stability, aiding in thermal management, offering chemical resistance, and enabling customization, the potting compound provides a comprehensive solution for safeguarding electronic components in these critical applications. As the automotive and industrial sectors continue to evolve, potting compound’s importance in ensuring electronic assemblies’ longevity and functionality cannot be overstated. Manufacturers and designers benefit from integrating potting compounds into their assembly processes, raising the standard for quality and reliability in automotive and coil applications.

About DeepMaterial

DeepMaterial is a trusted supplier of encapsulant materials that are used in electronics manufacturing worldwide. From chip on board encapsulants such as glob top material to conformal coatings, underfills, low pressure molding, and potting solutions, DeepMaterial offers a full range of circuit board protection materials that effectively protect circuit boards while help reduce costs. More…Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

Blogs & News

Potting compounds are at the frontline of electronics assembly, delivering effective protection in challenging environmental conditions while improving mechanical strength and offering high electric insulation. Used within a variety of industries, electrical potting compounds are found within a broad range of consumer electronics, as well as used in applications across the automotive, aerospace, and other industries where electronic assemblies are prevalent.

Common Mistakes to Avoid When Applying Conformal Coating

Common Mistakes to Avoid When Applying Conformal Coating In the world of electronics manufacturing, the difference between a product that lasts a decade and

How Does Potting and Encapsulation Protect Electronic Components?

How Does Potting and Encapsulation Protect Electronic Components? In an increasingly electrified and connected world, electronic components are deployed in environments ranging from the

How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation Potting, the process of encapsulating a printed circuit board (PCB)

How to Choose the Right Potting Material for Your PCB

How to Choose the Right Potting Material for Your PCB Printed Circuit Boards (PCBs) form the backbone of modern electronics, but their delicate

Basic Knowledge, Methods and Materials about Electronic Encapsulation

Basic Knowledge, Methods and Materials about Electronic Encapsulation In an era defined by ubiquitous electronics—from the smartphone in your pocket to the sensor monitoring

Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics The modern automobile has undergone a radical transformation, evolving from a predominantly mechanical machine