Conformal Coating Spray

- Electronic Potting Material Manufacturer

- August 19, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, circuit board potting, coating for electronic implants, coating heads adhesive application, coating material manufacturer, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating spray, conformal coating spray manufacturer, conformal coating spray market, conformal coating spray supplier, conformal coating suppliers, conformal coating types, electrical potting compound, electronic epoxy encapsulant potting compounds, epoxy encapsulation electronic components, epoxy encapsulation for photovolatics, epoxy encapsulation led, epoxy encapsulation meaning, epoxy encapsulation molding compound, epoxy potting compound, epoxy resin encapsulation, epoxy resin encapsulation solar panels, pcb potting, polyurethane potting compound, polyurethane potting compound for electronics, potting compound for electronics, potting compound for pcb, potting compound vs epoxy, potting material for electronic components, potting material for electronics, potting pcb, silicone potting compound for electronics, UV curing potting compound, waterproof potting compound, what is pcb potting

Conformal Coating Spray

In the fast-paced world of electronics, protecting printed circuit boards (PCBs) from environmental hazards is essential to ensure reliability and longevity. Conformal coating sprays offer a practical and efficient solution, applying a thin, protective film to PCBs to shield them from moisture, dust, chemicals, and mechanical stress. As a widely used method in industries like automotive, aerospace, and consumer electronics, conformal coating sprays provide robust protection while maintaining the lightweight and compact nature of modern devices.

Conformal coating sprays stand out for their ease of application, allowing manufacturers to coat complex PCB geometries quickly and effectively. By forming a barrier against environmental threats, these sprays prevent corrosion, electrical shorts, and performance degradation, extending the lifespan of electronics. This article delves into the essentials of conformal coating sprays, covering their properties, types, application techniques, benefits, challenges, and selection criteria. Whether you’re an engineer optimizing a production line or a hobbyist safeguarding a custom PCB, this guide will equip you with the knowledge to leverage conformal coating sprays effectively.

What is Conformal Coating Spray?

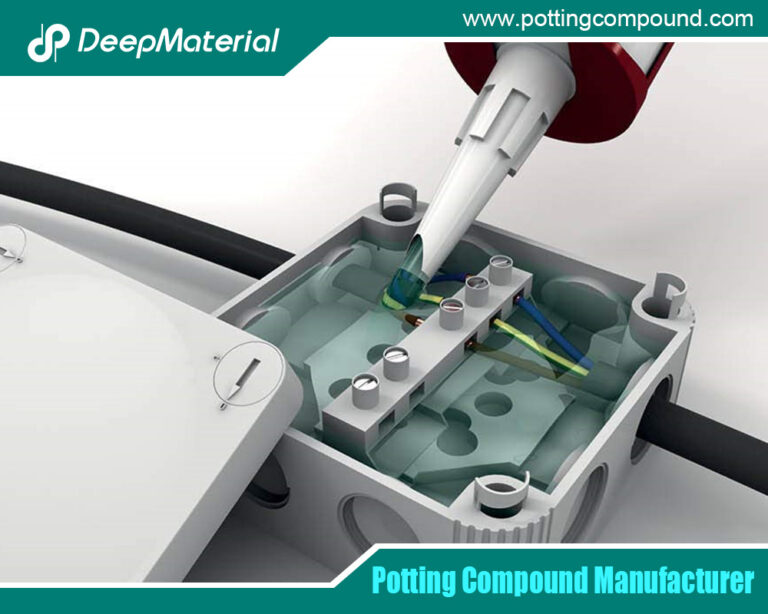

A conformal coating spray is a method of applying a thin, polymeric film to the surface of a printed circuit board using a spray mechanism. The coating, typically 25 to 250 micrometers thick, “conforms” to the PCB’s contours, covering components, solder joints, and exposed traces to protect them from environmental stressors like moisture, dust, chemicals, and temperature extremes. Unlike potting, which fully encapsulates electronics, conformal coatings allow access for repairs while providing a protective barrier.

Conformal coating sprays are formulated from materials such as acrylics, polyurethanes, silicones, or UV-curable resins, each offering specific properties like flexibility, chemical resistance, or thermal stability. The spray application can be manual (using aerosol cans or handheld sprayers), semi-automated, or fully automated (using robotic systems), making it versatile for both small-scale and high-volume production.

Compared to other application methods like dipping or brushing, spraying offers speed, precision, and the ability to coat complex geometries without excessive material buildup. It is particularly effective for covering large or irregularly shaped PCBs, though care must be taken to ensure uniform coverage. Conformal coating sprays are a cornerstone of electronics protection, ensuring PCBs perform reliably in diverse and challenging environments.

Key Properties of Conformal Coating Sprays

Conformal coating sprays are selected for their ability to protect PCBs while maintaining functionality. Key properties include:

- Electrical Insulation: High dielectric strength prevents electrical arcing and shorts, critical for densely packed PCBs with closely spaced traces operating at high voltages.

- Moisture and Chemical Resistance: Sprays form a barrier against water, humidity, and chemicals like solvents, oils, or acids, reducing corrosion and component degradation.

- Thermal Stability: Many coatings withstand temperatures from -65°C to over 200°C, protecting PCBs in extreme environments like automotive engines or aerospace systems.

- Mechanical Protection and Flexibility: Coatings absorb vibrations and mechanical shocks, protecting solder joints. Flexible formulations accommodate thermal expansion without cracking.

- Ease of Application and Coverage: Spray coatings conform to complex PCB geometries, ensuring uniform protection with minimal material waste when applied correctly.

These properties make conformal coating sprays versatile, balancing robust protection with practical considerations like application efficiency and reworkability. For example, acrylic sprays are favored for their ease of use, while silicone sprays excel in high-temperature applications. The choice depends on the PCB’s operating conditions and production requirements.

Types of Conformal Coating Sprays

Conformal coating sprays are available in various formulations, each suited to specific applications. The main types include:

- Acrylic Sprays: Known for their ease of application and removal, acrylics provide good moisture resistance and electrical insulation. They are cost-effective for general-purpose applications like consumer electronics. Pros: Easy to apply/rework, affordable, good insulation.

Cons: Limited chemical and high-temperature resistance.

- Polyurethane Sprays: These offer excellent chemical resistance and toughness, ideal for harsh environments like automotive or industrial systems. They are more durable but harder to remove. Pros: Strong chemical resistance, flexible, durable.

Cons: Difficult to rework, longer curing times.

3. Silicone Sprays: Highly flexible and thermally stable, silicones perform well in extreme temperatures (-65°C to 200°C) and UV-exposed environments, suitable for aerospace or outdoor applications. Pros: Wide temperature range, UV resistance, flexible.

Cons: Expensive, challenging to remove.

4. UV-Curable Sprays: These cure rapidly under UV light, enabling high-throughput production. They offer good moisture resistance and are used in applications requiring fast processing, like LED manufacturing. Pros: Rapid curing, precise application, good protection.

Cons: Requires UV equipment, limited penetration in shadowed areas.

5. Each type is tailored to address specific environmental, mechanical, or production challenges, allowing manufacturers to select the optimal spray for their PCB needs.

Application Process for Conformal Coating Sprays

Applying conformal coating sprays involves several steps to ensure effective protection:

- PCB Preparation: Clean the PCB to remove contaminants like dust, oils, or flux residues using solvents or ultrasonic cleaning. Mask areas that should remain uncoated, such as connectors or test points, with tape or peelable masks.

- Spray Application:

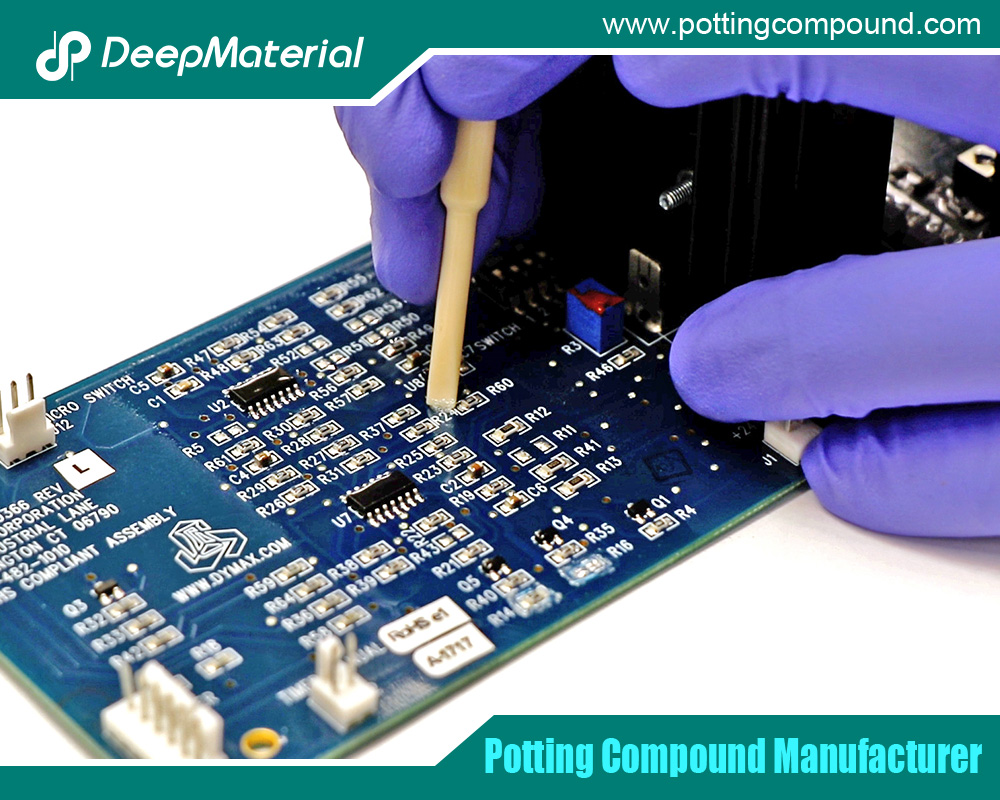

- Manual Spraying: Aerosol cans or handheld sprayers are used for low-volume or prototype work, offering flexibility but requiring operator skill for uniformity.

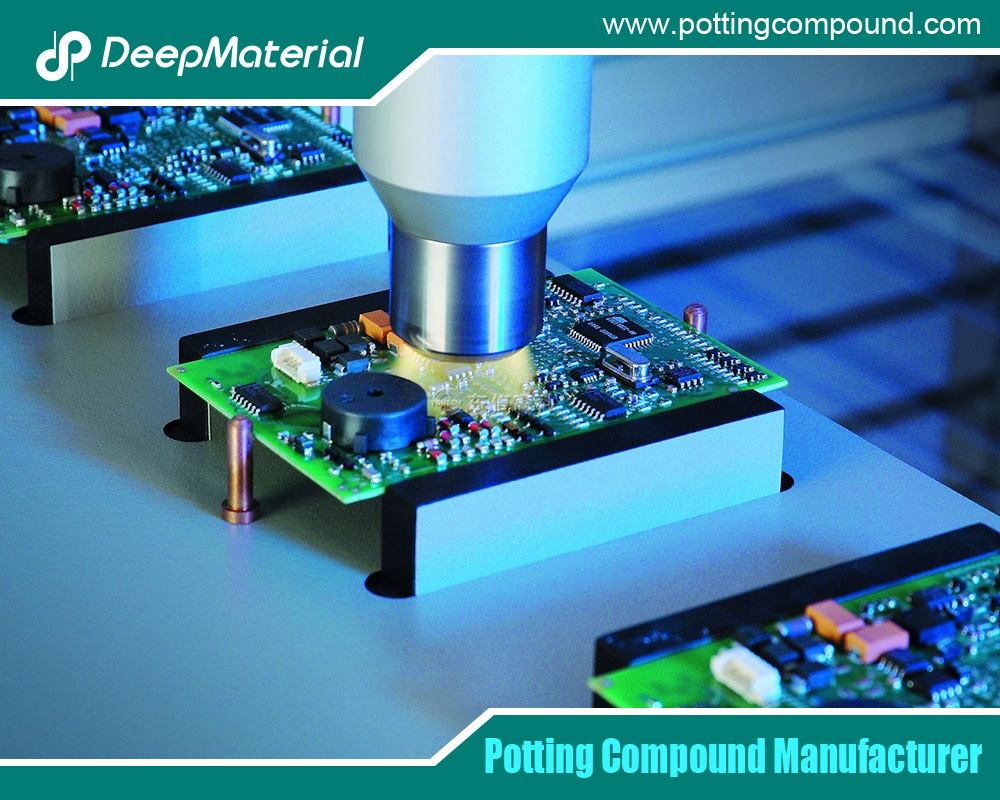

- Automated Spraying: Robotic or conveyor-based systems apply precise, consistent coatings in high-volume production, using selective spraying to avoid masked areas.

- Aerosol Sprays: Convenient for small-scale or field repairs, aerosols provide quick application but may result in overspray.

3. Curing: Depending on the coating type, curing occurs via air drying (acrylics, polyurethanes), heat (some polyurethanes), or UV light (UV-curable sprays). Curing times range from seconds (UV) to hours (air-dried).

4. Quality Control and Inspection: Inspect coatings for uniformity, thickness, and defects like bubbles or pinholes using visual checks, UV fluorescence (for certain coatings), or automated optical inspection (AOI).

Proper application ensures optimal protection, with automated systems offering greater consistency for large-scale production. Ventilation and safety measures are critical due to solvent vapors in some sprays.

Applications of Conformal Coating Sprays

Conformal coating sprays are used across diverse industries to protect PCBs in challenging environments. Key applications include:

- Consumer Electronics: Smartphones, tablets, wearables, and home appliances use sprays to shield PCBs from humidity, dust, and spills, ensuring reliability in daily use.

- Automotive Electronics: Engine control units (ECUs), sensors, and infotainment systems rely on sprays to withstand heat, oil, vibrations, and road salt in vehicles.

- Aerospace and Defense: Avionics, radar, and communication systems use sprays to endure extreme temperatures, high altitudes, and mechanical stress, ensuring mission-critical performance.

- Industrial Equipment: Motors, control systems, and sensors in factories benefit from sprays that resist chemicals, dust, and temperature fluctuations in harsh settings.

- Medical Devices: PCBs in diagnostic tools and wearables use sprays to protect against humidity and sterilization processes, ensuring reliability in clinical environments.

- Renewable Energy Systems: Solar inverters and wind turbine controllers use sprays to resist UV exposure, rain, and thermal cycling in outdoor installations.

These applications highlight the versatility of conformal coating sprays, which are tailored to meet industry-specific demands while enabling efficient production.

Benefits of Conformal Coating Sprays

Conformal coating sprays offer several advantages, making them a preferred choice for PCB protection:

- Effective Environmental Protection: Sprays shield PCBs from moisture, chemicals, dust, and UV exposure, preventing corrosion and electrical failures.

- Simplified Application Process: Spraying is fast and adaptable, suitable for complex PCB geometries and scalable from prototypes to mass production.

- Lightweight and Space-Saving: Thin coatings add minimal weight or bulk, ideal for compact electronics like wearables or drones.

- Reworkability: Acrylic and some UV-curable sprays can be easily removed for repairs, reducing maintenance costs.

- Cost-Effectiveness: Sprays provide robust protection at a lower cost than potting, offering long-term savings by reducing failures.

These benefits make conformal coating sprays an efficient and reliable solution for manufacturers seeking to balance protection and production efficiency.

Challenges and Considerations

Despite their advantages, conformal coating sprays present challenges:

- Uniformity and Coverage Issues: Achieving consistent thickness on complex PCBs can be difficult, especially with manual spraying, risking pinholes or thin spots.

- Overspray and Waste: Excess spray can coat unintended areas or be wasted, requiring masking and cleanup, particularly with aerosols or manual methods.

- Equipment and Ventilation Requirements: Automated systems and UV curing equipment add upfront costs, and solvent-based sprays require proper ventilation to ensure worker safety.

- Material Compatibility: Some sprays may not adhere well to certain PCB materials, risking delamination if compatibility is not tested.

- Environmental Impact: Solvent-based sprays may emit volatile organic compounds (VOCs), requiring compliance with environmental regulations.

Manufacturers can mitigate these challenges by using automated systems, testing compatibility, and selecting low-VOC or water-based sprays where possible.

How to Choose the Right Conformal Coating Spray

Selecting the appropriate conformal coating spray involves evaluating several factors:

- Environmental Conditions: Assess exposure to moisture, chemicals, UV light, or temperature extremes to choose a resistant formulation (e.g., silicone for high temperatures).

- Electrical Requirements: Ensure the spray’s dielectric strength meets the PCB’s voltage demands to prevent arcing.

- Application Method: Confirm compatibility with manual, automated, or aerosol spraying based on production scale and equipment.

- Reworkability: Consider whether the coating needs to be removable (e.g., acrylics) or permanent (e.g., polyurethanes).

- Certifications: Look for sprays meeting standards like UL, IPC-CC-830, or MIL-I-46058C for regulatory compliance.

- Budget: Balance performance with cost, especially for high-volume production.

Testing samples and collaborating with suppliers can help identify the best spray, ensuring optimal protection and efficiency for your PCB application.

Conclusion

Conformal coating sprays are a vital tool for protecting PCBs in today’s demanding environments, offering efficient application, robust protection, and design flexibility. Their applications across industries—from consumer electronics to aerospace—highlight their importance in ensuring reliability and longevity. By understanding their properties, types, and application techniques, manufacturers can leverage conformal coating sprays to enhance product performance and durability.

As technology evolves, innovations like eco-friendly sprays and automated application systems promise to further improve their utility. For engineers and manufacturers, exploring the range of conformal coating sprays available today is a critical step toward building resilient electronics. Consult with suppliers, test samples, and evaluate your needs to find the perfect spray, ensuring your PCBs thrive in even the most challenging conditions.

For more about choosing the conformal coating spray, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB