The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- Electronic Potting Material Manufacturer

- December 16, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, Automotive potting material manufacturers, Benefits of Potting Electronics, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, china electronic potting silicone manufacturer, china electronic potting silicone supplier, circuit board potting, circuit board potting compound, circuit board potting compounds, coating for electronic implants, coating heads adhesive application, coating material manufacturer, conformal coating, conformal coating electronics, conformal coating for pcb, conformal coating for PCB market, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, Conformal Coating Material Manufacturer, Conformal Coating Material Supplier, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating silicone manufacturer, Connector Potting Compound, Connector Potting Process, custom automated electronics potting, LED Potting Compounds, LED Potting Glue, LED Potting Glue Market, led uv glue adhesive

The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

A Silent Guardian’s Moment in the Spotlight

In the intricate, unseen world within electronic devices, printed circuit boards (PCBs) form the foundational nervous system. For decades, a critical but often overlooked process has protected these delicate circuits from their operational environments: conformal coating. This thin polymeric film, applied to assembled PCBs, acts as a protective barrier against moisture, dust, chemicals, thermal shock, and fungal growth. Today, this once-niche segment of the electronics manufacturing ecosystem is experiencing unprecedented growth. The global conformal coating market is not merely expanding; it has entered a phase of explosive, transformative growth. Driven by technological revolutions and shifting global demands, this market is projected to surge from approximately $1.2 billion in 2023 to over $2.0 billion by 2028, exhibiting a robust Compound Annual Growth Rate (CAGR) of 9-12%. This article delves into the key drivers propelling this boom and examines the detailed insights provided by leading market reports.

From Optional Extra to Essential Enabler: Understanding the Market Shift

Traditionally, conformal coating was reserved for electronics destined for extreme environments—military, aerospace, and heavy industrial applications. The proliferation of electronics into every facet of modern life has fundamentally altered this calculus. The “perfect storm” of miniaturization, heightened performance expectations, and harsh deployment scenarios has elevated conformal coating from a specialized safeguard to a standard, critical component of reliability engineering. Market reports from firms like MarketsandMarkets, Grand View Research, and Yole Développement consistently highlight this paradigm shift, identifying several interconnected mega-trends as primary accelerants.

Key Driver 1: The Unstoppable March of Miniaturization and Increased Complexity

The most potent driver is the relentless trend toward smaller, denser, and more powerful electronics. The rise of High-Density Interconnect (HDI) PCBs and miniaturized components (like 0201 or 01005 packages) has reduced the spacing (pitch) between conductive traces to microscopic levels. This creates a heightened risk of electrochemical migration (dendrite growth) and short circuits caused by even minute contaminants or condensation. Conformal coating is essential in mitigating these risks, providing insulation and preventing current leakage. Furthermore, the adoption of mixed-technology boards combining traditional components with advanced systems-in-package (SiP) necessitates a protective layer that accommodates varied topographies without compromising performance.

Key Driver 2: Proliferation into Harsh and Unforgiving Environments

Electronics are no longer confined to climate-controlled offices and homes. The Internet of Things (IoT) and Industrial IoT (IIoT) are deploying sensor nodes and control units in factories (exposed to oils, coolants), agriculture (outdoors with humidity and pesticides), and utility infrastructure (temperature extremes). Automotive electronics, crucial for Advanced Driver-Assistance Systems (ADAS), infotainment, and engine control, must withstand under-hood temperatures, vibration, and exposure to fuels and road salts. Similarly, wearable medical devices and implants require coatings that are not only protective but also biocompatible. This expansion into diverse, challenging environments mandates tailored coating solutions—silicone for extreme thermal cycling, polyurethane for chemical resistance, acrylic for easy repairability—directly expanding the market’s breadth and value.

Key Driver 3: The Electric Vehicle (EV) and Renewable Energy Revolution

The global push toward electrification and sustainability is a colossal catalyst. An electric vehicle contains significantly more electronic content than a conventional car—battery management systems (BMS), power inverters, and charging modules. These high-voltage systems are particularly sensitive to contamination and humidity, which can lead to catastrophic failures. Conformal coatings are critical for ensuring the long-term reliability and safety of these components under demanding automotive conditions. Concurrently, the renewable energy sector—solar inverters and wind turbine controllers—deploys electronics in outdoor, high-humidity, and salty maritime atmospheres. The need for durable, long-lasting (25+ years) protection in these green technologies creates a substantial and growing demand segment.

Key Driver 4: Advancements in Coating Materials and Application Technologies

The market explosion is not solely demand-driven; supply-side innovations are enabling it. Material science has delivered advanced formulations:

- Fluoropolymer Coatings (e.g., Parylene):Offering exceptional barrier properties, ultra-thin deposition, and biocompatibility for critical medical and aerospace uses.

- UV-Curable Coatings:Enabling rapid, on-line curing for high-volume manufacturing, boosting throughput.

- Low-VOC and Bio-Based Materials:Addressing stringent environmental regulations (e.g., REACH, RoHS) and corporate sustainability goals.

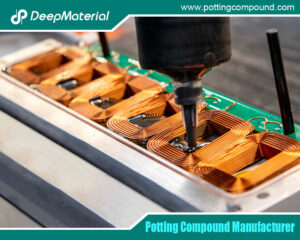

Equally important are application technologies. Selective coating machines, guided by precise robotic programming, can apply coating only where needed, avoiding connectors, heatsinks, and test points. This precision reduces waste, improves quality, and is essential for complex boards. The integration of these advanced materials and precise application methods makes conformal coating more effective, efficient, and environmentally compliant, removing previous adoption barriers.

Key Driver 5: Geopolitical and Supply Chain Resilience

Recent global disruptions have underscored the critical importance of supply chain security and longevity. Manufacturers can no longer afford high failure rates due to environmental factors, especially for electronics embedded in long-lifecycle capital equipment. Conformal coating is increasingly viewed as a cost-effective insurance policy, enhancing product reliability, reducing warranty claims, and protecting brand reputation. This focus on Design for Reliability (DfR) and Lifecycle Engineering is embedding coating consideration earlier in the design process, further institutionalizing its use.

Market Reports Detailed: Segmentation and Regional Insights

Leading market analyses provide granular detail on this growth trajectory:

- By Material Type:The market is segmented into Acrylic, Silicone, Polyurethane, Epoxy, Parylene, and others. Silicone holds a dominant share for its flexibility and wide temperature range, while acrylic is favored for mass production due to its fast drying and easy rework. Parylene, though expensive, is the fastest-growing segment for ultra-high-reliability applications.

- By Application Method:Spray coating (both manual and automated) leads in volume, but selective coating is growing fastest due to precision and material savings. Dip coating remains relevant for high-volume, full-coverage needs.

- By End-Use Industry:Consumer electronics remains the largest volume sector, but automotive, aerospace & defense, and medical are the highest-value and fastest-growing segments, driven by their stringent reliability requirements.

- By Region:

- Asia-Pacific:The undisputed leader, accounting for over 45% of the global market. This is driven by the region’s dominance in electronics manufacturing, especially in China, South Korea, Taiwan, and the burgeoning markets of Vietnam and India.

- North America & Europe:Mature but innovation-led markets, characterized by high demand for advanced materials (Parylene, fluoropolymers) in aerospace, defense, medical, and automotive industries. Stricter environmental regulations here also drive the adoption of new, compliant chemistries.

Challenges and the Road Ahead

Despite the boom, challenges persist. The rework and repair of coated boards remain skilled, time-intensive tasks. Developing coatings that balance high performance with ease of removal for specific areas is an ongoing R&D focus. Process control and inspection are critical; voids, pinholes, or insufficient coverage can render the coating useless. Advanced inspection techniques like 3D scanning and automated optical inspection (AOI) for coatings are becoming necessary. Furthermore, the industry must continue to evolve sustainable solutions, reducing the environmental footprint of both the materials and the application processes.

Conclusion

The explosive growth of the conformal coating market is a direct response to the evolving landscape of global electronics. It is a foundational technology enabling the next wave of innovation—from autonomous vehicles and smart cities to wearable health monitors and space exploration. No longer a mere afterthought, conformal coating is now a strategic consideration integral to product design, reliability, and compliance. As electronics continue to become more pervasive, complex, and mission-critical, the thin, protective layer of conformal coating will stand as an indispensable guardian, ensuring that the digital heart of our world keeps beating reliably, regardless of the environment it calls home. The reports are clear: this explosive period is not a transient spike but the new baseline for a market whose essential role is now fully recognized and irreversibly entrenched.

For more about the conformal coating for PCB market has entered an explosive period: key drivers and reports detailed, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Conformal Coating vs. Potting: What’s the Difference for Your PCB?

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

Tags

Related Posts

Common Mistakes to Avoid When Applying Conformal Coating

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB