Conformal Coating Waterproof: Protecting Electronics from Water Damage

- Electronic Potting Material Manufacturer

- October 10, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, Ceramic Potting Compound, circuit board potting compound, circuit board potting compounds, conformal coating, conformal coating electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, Conformal Coating Material Manufacturer, Conformal Coating Material Supplier, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating silicone manufacturer, Conformal Coatings, Conformal Coatings for Electronic, conformal coatings for electronics applications, conformal coatings market for automotive electronics, Connector Potting Compound, deepmaterial potting compound, deepmaterial potting compound manufacturer, Industrial Conformal Coatings, potting compound, sharp edge coverage conformal coatings, Silicone Conformal Coatings, Silicone Conformal Coatings Manufacturer, Waterproof Conformal Coatings, Waterproof Conformal Coatings Manufacturer, Waterproof Conformal Coatings Supplier

Conformal Coating Waterproof: Protecting Electronics from Water Damage

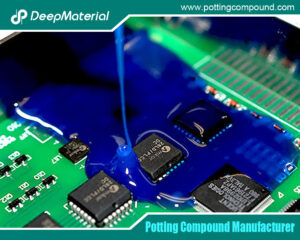

In the world of electronics, protecting printed circuit boards (PCBs) from environmental factors is critical to ensuring reliability and longevity. Among these factors, water exposure—whether from humidity, condensation, or direct immersion—poses a significant threat, leading to corrosion, electrical shorts, and component failure. Conformal coatings waterproof, thin polymeric films applied to PCBs, are designed to provide a protective barrier, with waterproofing being a key function for many applications. This article explores the role of conformal coatings in waterproofing electronics, detailing the materials, properties, application processes, standards, testing methods, and emerging trends that enable effective water resistance in industries such as automotive, aerospace, medical, and consumer electronics.

Understanding Waterproof Conformal Coatings

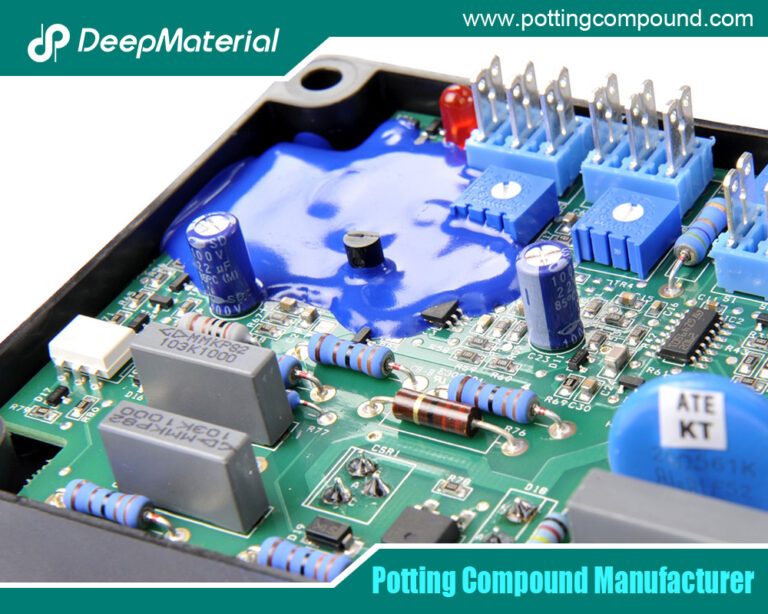

Conformal coatings are protective layers, typically 25–250 micrometers thick, that conform to the contours of PCBs and their components. They shield electronics from environmental stressors, including moisture, dust, chemicals, and temperature extremes. Waterproofing, in the context of conformal coatings, refers to the ability to prevent water ingress, whether from ambient humidity, rain, or immersion, thereby protecting circuits from corrosion and electrical failures.

While no conformal coating is entirely impervious to water under all conditions (e.g., prolonged submersion in high-pressure environments), many coatings provide excellent moisture resistance, often referred to as “waterproof” in practical terms. The effectiveness of a coating’s waterproofing depends on its material properties, application quality, and adherence to industry standards like IPC-CC-830 and MIL-I-46058C.

Why Waterproofing is Critical for PCBs

Water exposure can devastate electronic assemblies by:

- Corrosion: Moisture can corrode metal traces and solder joints, degrading performance.

- Electrical Shorts: Water can create unintended conductive paths, causing short circuits.

- Dielectric Breakdown: Moisture reduces insulation resistance, leading to electrical failures.

- Component Degradation: Prolonged exposure can damage sensitive components like capacitors or sensors.

Industries such as marine electronics, outdoor lighting, automotive systems, and medical devices require robust waterproof protection to ensure functionality in humid, wet, or submerged environments. Conformal coatings provide a cost-effective solution compared to fully sealed enclosures, balancing protection with design flexibility.

Types of Conformal Coatings for Waterproofing

Several conformal coating materials offer waterproofing capabilities, each with unique properties suited to specific applications. Below are the primary types, their waterproofing characteristics, and their applications:

- Acrylic Coatings (AR)

Properties: Acrylics form a flexible, transparent film with excellent moisture resistance, operating from -55°C to 125°C. They are solvent-based or water-based and easy to apply.

Waterproofing: Provide good protection against humidity and light water exposure but may not withstand prolonged immersion or high-pressure water.

Applications: Consumer electronics (e.g., smartphones, wearables), automotive control modules, and indoor industrial equipment.

Advantages: Cost-effective, reworkable, good dielectric strength (2,000 V/mil).

Disadvantages: Limited resistance to immersion or aggressive chemicals.

- Polyurethane Coatings (UR)

Properties: Polyurethanes create a tough, durable film with excellent chemical and moisture resistance, operating from -55°C to 130°C.

Waterproofing: Highly effective against humidity, condensation, and moderate water exposure, including saltwater in marine environments.

Applications: Automotive electronics, marine systems, industrial controls.

Advantages: Superior chemical and abrasion resistance, durable in harsh conditions.

Disadvantages: Difficult to rework, longer curing times.

- Silicone Coatings (SR)

Properties: Silicone coatings are flexible, elastomeric films with a wide temperature range (-55°C to 200°C) and UV stability.

Waterproofing: Excellent moisture resistance, suitable for humid environments and occasional water exposure. Their flexibility ensures a reliable seal during thermal cycling.

Applications: Aerospace electronics, LED lighting, medical devices, outdoor sensors.

Advantages: High thermal stability, vibration resistance, UV resistance.

Disadvantages: Higher cost, tacky surface may attract dust.

- Epoxy Coatings (ER)

Properties: Epoxies form a rigid, mechanically robust film with strong chemical resistance, operating from -55°C to 150°C.

Waterproofing: Provide excellent moisture resistance but may crack under thermal expansion, compromising the seal in dynamic environments.

Applications: Military electronics, heavy industrial equipment, oil and gas systems.

Advantages: High durability, strong adhesion.

Disadvantages: Rigid, difficult to rework, prone to cracking.

- Parylene Coatings (XY)

Properties: Parylene is applied via vapor deposition, forming a thin, pinhole-free film with exceptional barrier properties and biocompatibility, operating from -200°C to 150°C.

Waterproofing: Offers superior moisture resistance, ideal for immersion and high-humidity environments due to its uniform, conformal coverage.

Applications: Medical implants, aerospace electronics, MEMS, high-reliability sensors.

Advantages: Uniform, biocompatible, excellent dielectric strength (5,000 V/mil).

Disadvantages: High cost, requires specialized equipment, rework challenges.

- UV-Curable Coatings

Properties: These coatings, often based on acrylic or silicone resins, cure rapidly under UV light, offering customizable properties and low VOCs.

Waterproofing: Provide good moisture resistance, suitable for humid environments, but shadow areas may require secondary curing for complete sealing.

Applications: Consumer electronics, automotive sensors, high-throughput production.

Advantages: Fast curing, eco-friendly, versatile.

Disadvantages: Requires UV equipment, potential for uncured areas.

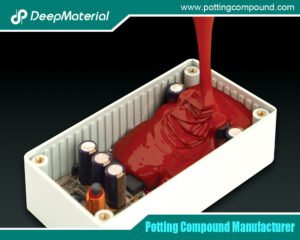

The Conformal Coating Process for Waterproofing

Achieving effective waterproofing requires a precise conformal coating process, involving several key steps:

- Material Selection

Select a coating material based on the level of water exposure:

- Humidity/Condensation: Acrylics or UV-curable coatings suffice for indoor or moderate environments.

- Splash/Immersion: Polyurethane, silicone, or Parylene are better for marine or outdoor applications.

- Standards: Ensure compliance with IPC-CC-830 (e.g., Type SR for silicone) or MIL-I-46058C for waterproof performance.

- Surface Preparation

A clean, contaminant-free surface is critical for adhesion and waterproofing:

- Cleaning: Remove flux residues, oils, or dust using solvents, aqueous cleaners, or plasma cleaning. Plasma cleaning enhances wettability for better sealing.

- Masking: Protect connectors, test points, or sensitive components with tapes or peelable masks to ensure precise coating application.

- Priming: Apply a primer for materials like silicone or Parylene to enhance adhesion on low-energy surfaces.

- Standards: IPC-CC-830 requires a clean surface to prevent defects like pinholes, which compromise waterproofing.

- Application Methods

The application method impacts the coating’s ability to form a waterproof barrier:

- Brushing: Manual, suitable for small-scale or rework tasks; requires skill to avoid defects.

- Spraying: Automated or manual, ideal for uniform coverage in high-volume production.

- Dipping: Ensures complete coverage for complex geometries, critical for immersion resistance.

- Selective Coating: Robotic systems apply coating precisely, minimizing gaps that could allow water ingress.

- Vapor Deposition (Parylene): Provides pinhole-free films, ideal for high-reliability waterproofing.

- Standards: IPC-CC-830 specifies thickness ranges (e.g., 50–210 µm for silicones) and defect-free films for waterproof performance.

- Curing

Curing solidifies the coating, ensuring a robust waterproof barrier:

- Moisture Cure: Common for silicones, curing via ambient humidity (24–48 hours).

- Heat Cure: Accelerates curing for polyurethanes or silicones (30 minutes to hours at 60–100°C).

- UV Cure: Rapid curing for UV-curable coatings, requiring secondary curing for shadow areas.

- Room-Temperature Cure: Used for some acrylics, taking hours to days.

- Standards: IPC-CC-830 defines curing conditions to ensure film integrity and waterproofing.

- Inspection and Testing

Inspection verifies the coating’s waterproofing effectiveness:

- Visual Inspection (IPC-CC-830): Checks for defects like bubbles, pinholes, or incomplete coverage that could allow water ingress.

- Thickness Measurement: Ensures compliance with specified ranges (e.g., 25–125 µm for acrylics) using micrometers or eddy-current probes.

- Moisture and Insulation Resistance (IPC-CC-830): Tests performance under high humidity (85% RH, 85°C).

- Water Immersion Testing (MIL-STD-810): Evaluates resistance to water exposure, simulating rain or submersion.

- Salt Spray Testing (ASTM B117): Assesses corrosion resistance in saline environments, critical for marine applications.

- Dielectric Strength (UL 746E): Verifies insulation properties under wet conditions.

- Standards: Compliance with IPC-CC-830, MIL-I-46058C, and MIL-STD-810 ensures reliable waterproofing.

Standards for Waterproof Conformal Coatings

Industry standards ensure conformal coatings provide effective waterproofing:

- IPC-CC-830: Qualifies coatings for moisture resistance, dielectric strength, and visual quality. Specifies types (AR, UR, SR, ER, XY) and thickness ranges.

- MIL-I-46058C: Military standard for high-reliability applications, requiring resistance to humidity, salt spray, and thermal cycling.

- MIL-STD-810: Tests environmental durability, including water immersion and humidity exposure.

- UL 746E: Ensures safety and flammability compliance, critical for consumer electronics exposed to moisture.

- IEC 61086: International standard for coating performance, including moisture resistance.

- ISO 9001: Mandates consistent processes for application, curing, and quality control.

Compliance involves rigorous testing and documentation, ensuring coatings meet waterproofing requirements for specific applications.

Challenges in Achieving Waterproof Conformal Coatings

- Defect Control: Pinholes, bubbles, or uneven thickness can compromise waterproofing. Automated application and inspection mitigate these issues.

- Material Limitations: No coating is fully waterproof under extreme conditions (e.g., prolonged submersion). Parylene offers the best resistance but is costly.

- Shadow Areas: UV-curable coatings may not cure in shielded areas, requiring secondary curing for complete sealing.

- Adhesion Issues: Poor surface preparation can lead to delamination, allowing water ingress.

- Cost vs. Performance: High-performance coatings like Parylene are expensive, while acrylics may not suffice for immersion scenarios.

Emerging Trends in Waterproof Conformal Coatings

The conformal coating industry is evolving to enhance waterproofing capabilities:

- Nanocoatings: Ultra-thin films (nanometer-scale) provide lightweight, effective waterproofing for miniaturized electronics.

- UV-Curable Hybrids: Combine rapid curing with silicone or polyurethane properties for enhanced moisture resistance.

- Low-VOC Formulations: Eco-friendly coatings reduce environmental impact while maintaining waterproof performance.

- Automation: Robotic selective coating systems ensure precise application, minimizing gaps that could allow water ingress.

- Hydrophobic Coatings: Fluoropolymer-based coatings with low surface energy enhance water repellency for extreme environments.

These trends address the growing demand for reliable waterproofing in compact, high-performance electronics.

Conclusion

Conformal coatings play a vital role in waterproofing PCBs, protecting electronics from moisture-related failures in diverse applications. Materials like acrylic, polyurethane, silicone, epoxy, Parylene, and UV-curable coatings offer varying levels of water resistance, with Parylene and silicone excelling in demanding environments. The conformal coating process—material selection, surface preparation, application, curing, and testing—must be meticulously controlled to ensure a robust waterproof barrier. Compliance with standards like IPC-CC-830, MIL-I-46058C, and MIL-STD-810 guarantees performance, while emerging trends like nanocoatings and automation enhance waterproofing capabilities. By mastering the conformal coating process, manufacturers can safeguard electronics against water damage, ensuring reliability in challenging conditions.

For more about conformal coating waterproof: protecting electronics from water damage, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

- Which Glues Are Suitable for Encapsulation of Electronic Products?

- What Are the Design Standards for the Glass Transition Temperature (Tg) and Tensile Modulus of Automotive Electronic Encapsulants Adhesives?

- Usage Methods of LED Potting Compounds: From Mixing to Curing – A Complete Step-by-Step Guide

- The Characteristics of Thermal Conductivity, Waterproofness and Shock Resistance of LED Potting Compounds