Choose the Right Conformal Coating Process to Extend Electronic Component Lifespan by 5 Times

- Electronic Potting Material Manufacturer

- September 28, 2025

- Acrylic Conformal Coating, acrylic vs silicone conformal coating, Ceramic Potting Compound, Ceramic Potting Compound Manufacturer, circuit board potting compound, circuit board potting compounds, conformal coating, conformal coating electronics, conformal coating for electronics, conformal coating for pcb, conformal coating for pcb standards, Conformal Coating in Electronic, conformal coating in electronics market, conformal coating manufacturers, conformal coating market, conformal coating material, Conformal Coating Material Manufacturer, Conformal Coating Material Supplier, conformal coating material types, conformal coating overspray, conformal coating pcb, conformal coating process, conformal coating silicone, conformal coating silicone manufacturer, Conformal CoatingConformal Coating, Connector Potting Compound, deepmaterial potting compound, deepmaterial potting compound manufacturer, electric motor potting compound, electric motor potting compound china OEM, potting compound

Choose the Right Conformal Coating Process to Extend Electronic Component Lifespan by 5 Times

Conformal coatings are thin polymeric films applied to printed circuit boards (PCBs) to protect electronic components from environmental stressors such as moisture, dust, chemicals, and temperature extremes. The conformal coating process is a critical step in electronics manufacturing, ensuring reliability and longevity in applications ranging from consumer electronics to aerospace systems. This process involves material selection, surface preparation, application, curing, inspection, and quality control, all governed by industry standards like IPC-CC-830 and ISO 9001. This article explores the conformal coating process in detail, covering its steps, methods, materials, challenges, compliance requirements, and emerging trends, providing a thorough guide for manufacturers and engineers.

Overview of the Conformal Coating Process

The conformal coating process involves applying a protective layer, typically 25–250 micrometers thick, that conforms to the contours of PCBs and their components. The goal is to provide insulation, prevent corrosion, reduce electrical arcing, and enhance durability in harsh environments. The process is highly technical, requiring precision to achieve uniform coverage, defect-free films, and compliance with performance standards. Key steps include:

- Material Selection: Choosing the appropriate coating material based on application needs.

- Surface Preparation: Cleaning and priming the PCB to ensure adhesion.

- Application: Applying the coating using methods like spraying, dipping, or brushing.

- Curing: Solidifying the coating through heat, moisture, or UV exposure.

- Inspection and Testing: Verifying coating quality and performance.

- Rework (if needed): Removing and reapplying coating for repairs.

Each step must be carefully controlled to meet standards like IPC-CC-830, MIL-I-46058C, and UL 746E, ensuring reliability and regulatory compliance.

Step 1: Material Selection

Overview

The conformal coating process begins with selecting a material suited to the PCB’s operating environment and performance requirements. Common materials include acrylic, polyurethane, silicone, epoxy, Parylene, and UV-curable coatings, each with distinct properties.

Key Considerations

- Environmental Conditions: Assess exposure to moisture, chemicals, UV light, or temperature extremes. For example, silicone is ideal for high-temperature applications, while polyurethane excels in chemical resistance.

- Electrical Properties: Ensure high dielectric strength (e.g., 1,000–5,000 V/mil) for insulation.

- Application Method: Match the material’s viscosity and curing requirements to the chosen application method.

- Reworkability: Consider ease of removal for repairs (e.g., acrylics are reworkable, while epoxies are not).

- Standards Compliance: Select materials certified to IPC-CC-830 (e.g., Type AR for acrylic, SR for silicone) or MIL-I-46058C.

Common Materials

- Acrylic: Cost-effective, easy to apply, good for moderate environments.

- Polyurethane: Durable, chemically resistant, suitable for harsh conditions.

- Silicone: Flexible, thermally stable, ideal for high temperatures and vibrations.

- Epoxy: Rigid, mechanically robust, used in rugged environments.

- Parylene: Uniform, pinhole-free, applied via vapor deposition for high-reliability applications.

- UV-Curable: Fast-curing, eco-friendly, used in high-throughput production.

Process Impact

Material selection influences application methods, curing conditions, and equipment requirements, setting the foundation for a successful coating process.

Step 2: Surface Preparation

Overview

Proper surface preparation is critical to ensure coating adhesion and performance. Contaminants like flux residues, oils, or dust can cause defects such as delamination or pinholes.

Key Steps

- Cleaning: Remove contaminants using solvents (e.g., isopropyl alcohol), aqueous cleaners, or plasma cleaning. Plasma cleaning is increasingly used for its ability to remove organic residues and improve surface wettability.

- Masking: Cover areas not requiring coating (e.g., connectors, test points) with tapes, boots, or peelable masks. Masking ensures precise application and compliance with IPC-CC-830 visual standards.

- Priming (if needed): Apply a primer to enhance adhesion, especially for silicone or Parylene coatings on low-energy surfaces like plastics.

- Drying: Ensure the PCB is completely dry to prevent trapped moisture, which can lead to defects during curing.

Standards Compliance

IPC-CC-830 requires a clean, contaminant-free surface to achieve uniform coating and prevent defects. ISO 9001 mandates documented cleaning procedures for traceability.

Challenges

Inconsistent cleaning can lead to adhesion failures, while improper masking may result in coating on sensitive areas, affecting functionality.

Step 3: Application Methods

The application method determines coating uniformity, thickness, and production efficiency. Common methods include:

1. Brushing

- Description: Manual application using a brush for small-scale or prototype PCBs.

- Advantages: Low cost, suitable for touch-ups or rework.

- Disadvantages: Inconsistent thickness, labor-intensive, prone to operator error.

- Standards: Must meet IPC-CC-830 thickness requirements (e.g., 25–125 µm for acrylics).

2. Spraying

- Description: Applied via aerosol cans, spray guns, or automated spray systems.

- Advantages: Fast, suitable for high-volume production, achieves uniform coverage.

- Disadvantages: Overspray can waste material; requires ventilation and masking.

- Standards: Ensures consistent thickness per IPC-CC-830 and defect-free films.

3. Dipping

- Description: PCBs are immersed in a coating bath and withdrawn at a controlled rate.

- Advantages: Uniform coverage, ideal for complex geometries.

- Disadvantages: Requires precise viscosity control to avoid runs or bubbles.

- Standards: Meets IPC-CC-830 thickness and visual requirements.

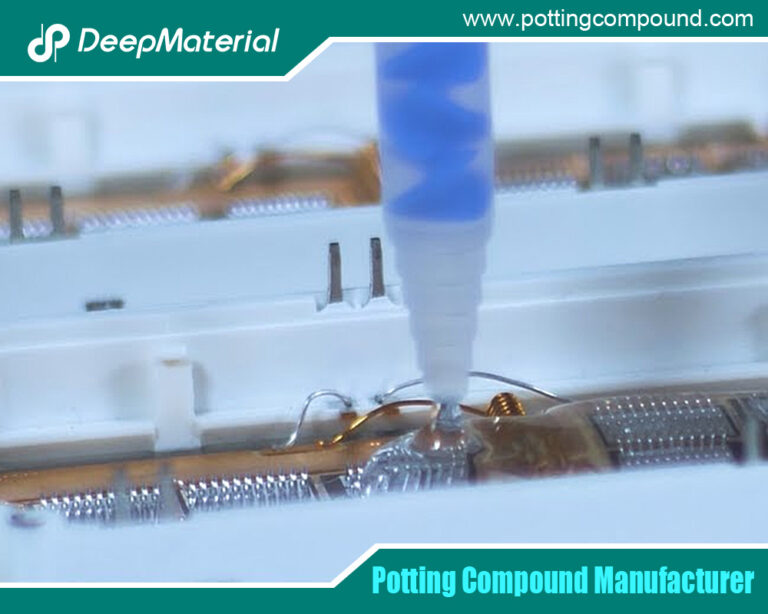

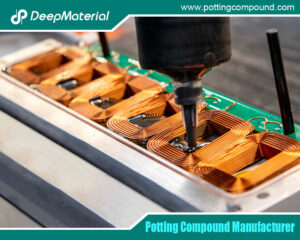

4. Selective Coating

- Description: Robotic systems dispense coating on specific PCB areas using nozzles or jets.

- Advantages: Precise, minimizes waste, supports high-throughput production.

- Disadvantages: High initial equipment cost, requires programming expertise.

- Standards: Aligns with ISO 9001 for process control and IPC-CC-830 for coverage.

5. Vapor Deposition (Parylene)

- Description: Parylene is deposited as a vapor in a vacuum chamber, forming a thin, uniform film.

- Advantages: Pinhole-free, excellent for complex geometries and high-reliability applications.

- Disadvantages: High cost, requires specialized equipment, limited to Parylene.

- Standards: Meets IPC-CC-830 (Type XY) and IEC 61086 requirements.

Process Considerations

The choice of method depends on production volume, PCB complexity, and material properties. Automated methods like selective coating and spraying enhance consistency and compliance with standards.

Step 4: Curing

Overview

Curing solidifies the conformal coating, forming a protective film with the desired properties. Curing methods vary by material and must be controlled to meet standards.

Curing Methods

- Moisture Cure: Common for silicones and some polyurethanes, curing occurs via ambient humidity (24–48 hours).

- Heat Cure: Accelerates curing for acrylics, polyurethanes, and silicones using ovens (30 minutes to several hours at 60–100°C).

- UV Cure: UV-curable coatings solidify in seconds under UV light, ideal for high-throughput production. Shadow areas may require secondary curing (moisture or heat).

- Room-Temperature Cure: Some acrylics cure at ambient conditions, taking hours to days.

- Vapor Deposition (Parylene): Curing occurs during deposition, requiring no additional step.

Standards Compliance

IPC-CC-830 specifies curing conditions to ensure film integrity. ISO 9001 requires documented curing parameters for consistency.

Challenges

Inconsistent curing can lead to incomplete films, tackiness, or reduced performance. UV-curable coatings require careful exposure to avoid uncured areas in shadowed regions.

Step 5: Inspection and Testing

Overview

Inspection and testing verify coating quality, ensuring compliance with standards and performance requirements. Key methods include:

- Visual Inspection (IPC-CC-830): Checks for defects like bubbles, pinholes, or uneven coverage using magnifying tools or automated optical inspection (AOI).

- Thickness Measurement: Uses micrometers, eddy-current probes, or cross-sectional analysis to verify thickness (e.g., 50–210 µm for silicones).

- Dielectric Strength (MIL-I-46058C, UL 746E): Tests insulation properties, typically 1,000–5,000 V/mil.

- Moisture and Insulation Resistance (IPC-CC-830): Evaluates performance under high humidity (85% RH, 85°C).

- Thermal Shock (MIL-I-46058C): Cycles between -55°C and 125°C to assess durability.

- Flammability (UL 746E): Ensures compliance with UL 94 ratings (e.g., V-0).

- Adhesion Testing (ASTM D3359): Verifies coating adhesion to the PCB substrate.

Process Impact

Rigorous inspection ensures defect-free coatings and compliance with standards, reducing the risk of field failures.

Step 6: Rework (if Needed)

Overview

Rework involves removing and reapplying coating for repairs or modifications. The ease of rework depends on the material:

- Acrylics: Easily dissolved with solvents like acetone.

- Silicone/Polyurethane: Require specialized solvents or mechanical methods (e.g., abrasion).

- Epoxy/Parylene: Extremely difficult, often requiring abrasive or laser techniques.

Process Considerations

Rework must maintain PCB integrity and comply with standards for reapplication. ISO 9001 requires documented rework procedures for traceability.

Challenges

Reworking silicone, epoxy, or Parylene coatings is time-consuming and costly, necessitating careful planning during material selection.

Standards Governing the Conformal Coating Process

The conformal coating process must comply with industry standards to ensure reliability:

- IPC-CC-830: Defines material qualification, application, and testing requirements for acrylic, polyurethane, silicone, epoxy, and Parylene coatings.

- MIL-I-46058C: Specifies performance for military applications, including thermal shock and fungus resistance.

- UL 746E: Ensures safety and flammability compliance for consumer and industrial electronics.

- IEC 61086: International standard for coating performance and application.

- ISO 9001: Ensures consistent processes, documentation, and quality control.

Compliance involves adhering to specified thickness ranges, curing conditions, and testing protocols, with traceability for quality assurance.

Challenges in the Conformal Coating Process

- Defect Control: Bubbles, pinholes, or uneven thickness can compromise protection. Automated systems and proper surface preparation mitigate these issues.

- Material Compatibility: Mismatched materials and application methods can lead to adhesion failures or curing issues.

- Shadow Areas: UV-curable coatings may not cure in areas shielded from light, requiring secondary curing methods.

- Cost vs. Performance: High-performance coatings like Parylene are costly, while low-cost acrylics may not meet stringent requirements.

- Environmental Regulations: Low-VOC and eco-friendly coatings are increasingly required, necessitating process adjustments.

Emerging Trends in the Conformal Coating Process

The conformal coating process is evolving to meet modern electronics demands:

- Automation: Robotic selective coating systems with real-time monitoring improve precision and compliance with ISO 9001.

- UV-Curable Coatings: Rapid curing reduces production time, with hybrid UV/moisture-cure systems addressing shadow areas.

- Sustainable Processes: Low-VOC and water-based coatings align with environmental regulations.

- Nanocoatings: Ultra-thin coatings for miniaturized electronics maintain performance while reducing material use.

- Smart Coatings: Self-healing or conductive coatings are emerging for advanced applications.

These trends enhance efficiency, sustainability, and adaptability in the coating process.

Conclusion

The conformal coating process is a critical aspect of PCB manufacturing, ensuring protection and reliability in diverse applications. By carefully selecting materials, preparing surfaces, applying coatings, curing, and inspecting, manufacturers can achieve defect-free films that meet standards like IPC-CC-830, MIL-I-46058C, and UL 746E. Despite challenges like defect control and rework, advancements in automation, UV-curable coatings, and sustainable processes are driving innovation. Understanding the conformal coating process enables engineers to optimize protection for electronics, from consumer devices to aerospace systems, ensuring performance in increasingly demanding environments.

For more about choose the right conformal coating process to extend electronic component lifespan by 5 times, you can pay a visit to DeepMaterial at https://www.pottingcompound.com/ for more info.

Recent Posts

- Common Mistakes to Avoid When Applying Conformal Coating

- How Does Potting and Encapsulation Protect Electronic Components?

- How to Prevent Voids in Circuit Board Potting: A Comprehensive Guide to Reliable Encapsulation

- How to Choose the Right Potting Material for Your PCB

- Basic Knowledge, Methods and Materials about Electronic Encapsulation

- Electronic Encapsulation Technology to Enhance the Durability of Automotive Electronics

- The Unsung Guardian: Why Silicone Potting Compound is Widely Used in the Electronics Industry

- The Development Trend and Future Prospects of Electrical Potting Compound in the Glue Industry

- The Conformal Coating for PCB Market Has Entered an Explosive Period: Key Drivers and Reports Detailed

- How Does Epoxy Encapsulated LED Work?

Tags

Related Posts

How Does Potting and Encapsulation Protect Electronic Components?

How to Choose the Right Potting Material for Your PCB